A body-in-white quality management method and system

A quality management and body-in-white technology, applied in the field of quality management, can solve problems such as error-prone input data, energy consumption, and poor sharing, and achieve the effect of improving quality inspection and production efficiency, improving efficiency, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

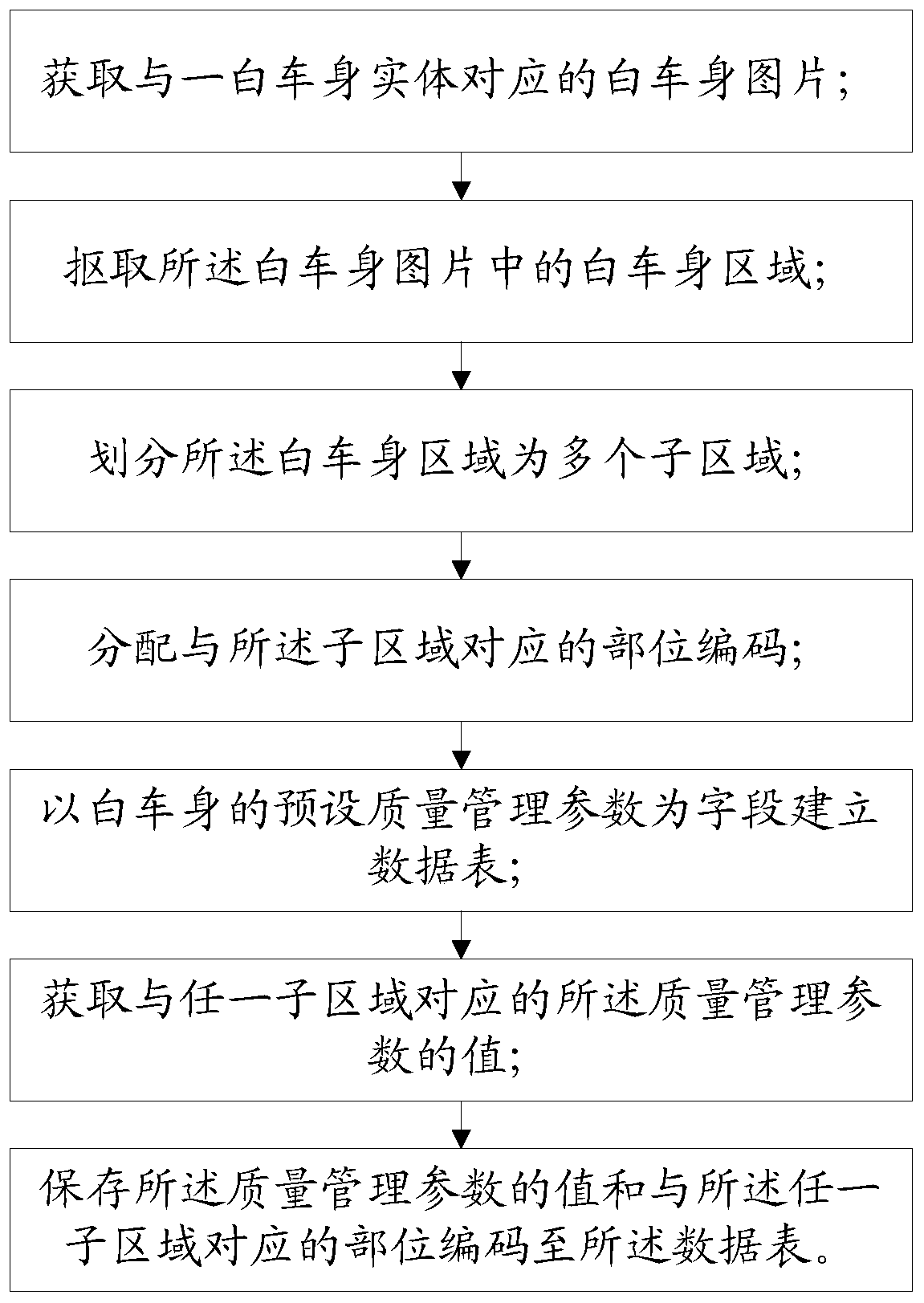

[0080] This embodiment provides a body-in-white quality management method, including:

[0081] S1. Acquire a body-in-white picture corresponding to a body-in-white entity; extract the body-in-white area in the body-in-white picture; divide the body-in-white area into multiple sub-areas; assign part codes corresponding to the sub-areas;

[0082] Wherein, the body-in-white area is divided into multiple sub-areas, specifically:

[0083] The body-in-white area is gridded into multiple sub-areas; the side length of each grid ranges from 100 mm to 200 mm; the corresponding grid is displayed on the body-in-white picture, and the corresponding grid is marked in each grid The part number of the sub-area;

[0084] For example, divide the body-in-white area except the background in the body-in-white picture into 63 sub-areas, and mark the corresponding part code in each grid, so that employees can quickly, intuitively and accurately match the corresponding ones when entering quality management p...

Embodiment 2

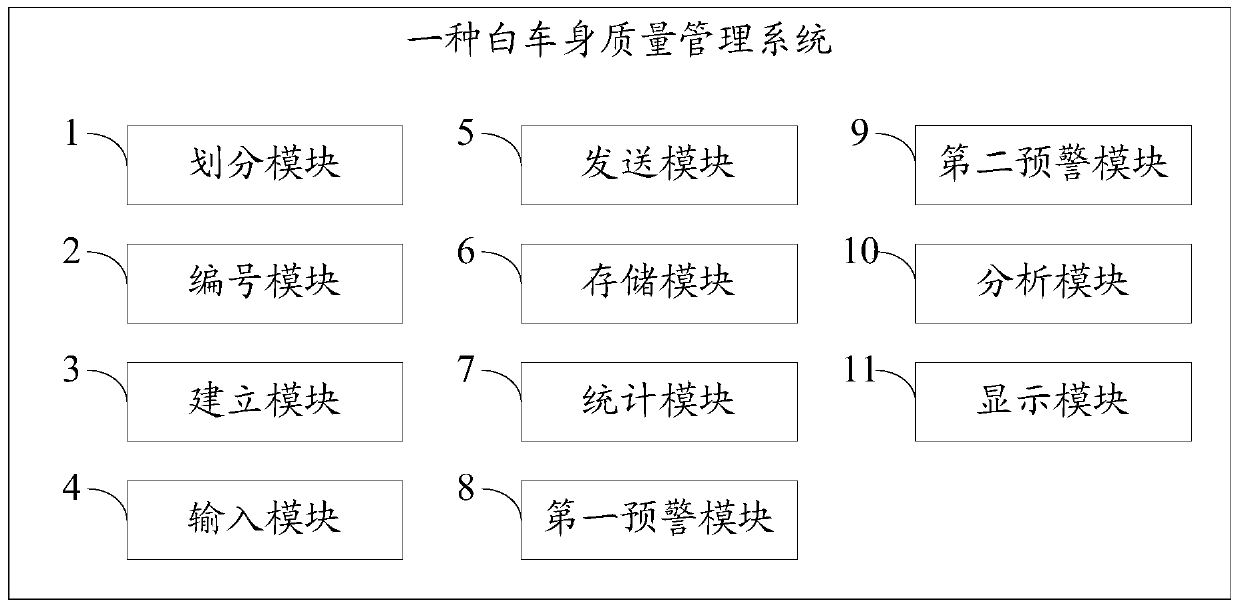

[0099] This embodiment provides a body-in-white quality management system, including:

[0100] The division module 1 obtains a body-in-white picture corresponding to a body-in-white entity; extracts the body-in-white area in the body-in-white picture; meshes the body-in-white area into multiple sub-areas; the side length value range of each grid It is 100 mm to 200 mm; the numbering module 2 assigns the part code corresponding to the sub-region; displays the corresponding grid on the white body picture, and marks the part number of the corresponding sub-region in each grid; establishes the module 3 Create a data table with the preset quality management parameters of the BIW as the fields; the quality management parameters include date, damage type, welding gun number, employee number, weld nugget diameter, size, and part code;

[0101] Select any one of the sub-regions through the input module 4, and enter the value of the quality management parameter corresponding to any one of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com