Zone collaborative optimization policy-based order processing method for automatic sorting system

An automatic sorting system and order processing technology, applied in data processing applications, instruments, commerce, etc., can solve the problems of high error rate, high labor intensity of workers, low efficiency of manual sorting, etc., to improve processing capacity and overcome efficiency. The effect of low, good application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the drawings:

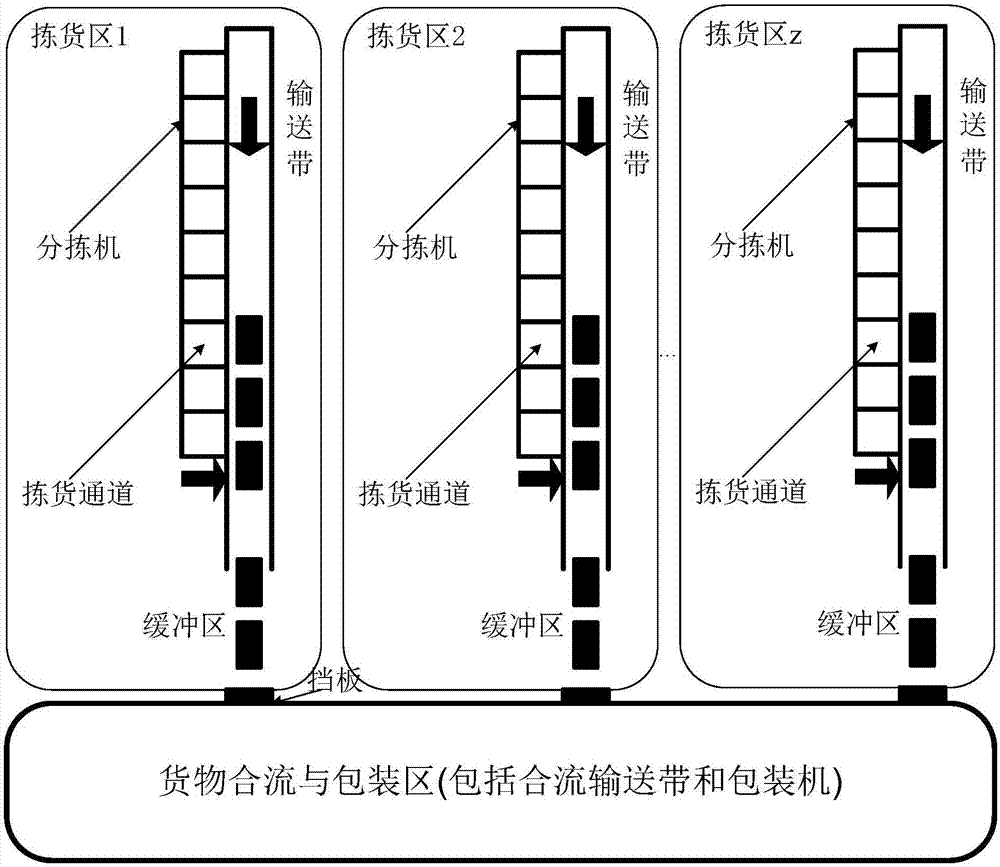

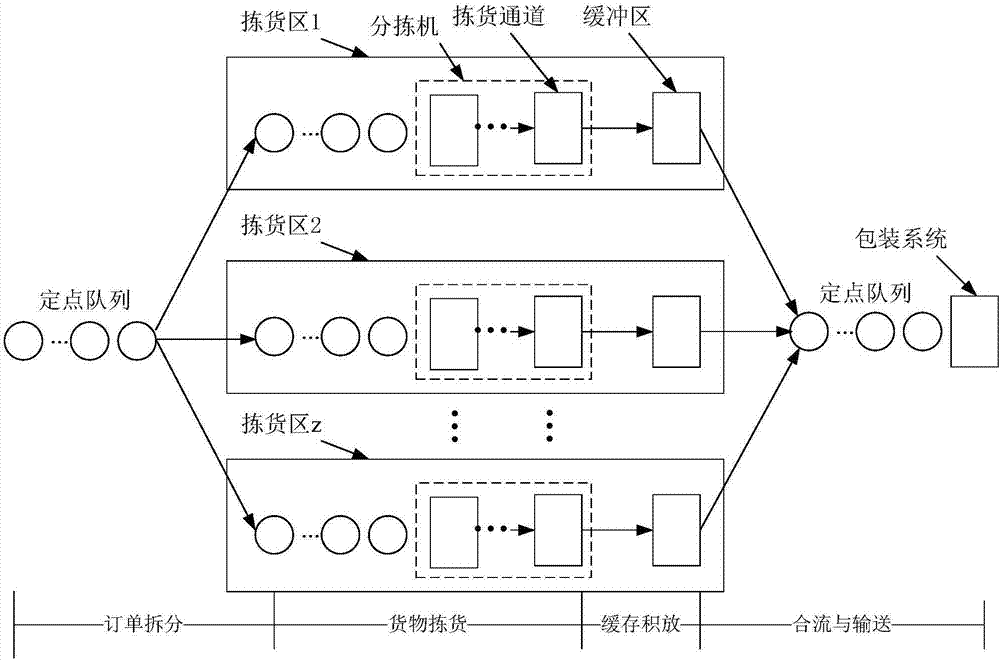

[0022] Reference figure 1 with figure 2 , The order processing method of automatic sorting system based on partition collaborative optimization strategy, including the following steps:

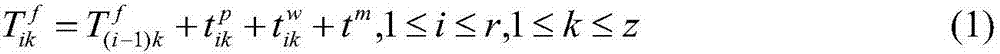

[0023] Step 1. Construct a mathematical analysis model of the order processing of the partition collaborative optimization sorting system: the key to order processing is how to minimize the total processing time. In order to obtain the structure of the total order processing time, it is necessary to analyze the system layout and the partition picking strategy. Work flow; such as figure 1 As shown, under the zoning picking strategy, the sorter system is divided into multiple independent picking areas, and a main conveyor belt is connected to the buffer at the end of each picking area; when processing orders, the sorters in each picking area pick the same The order goods are sent to the buffer zone, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com