Intelligent grain combine bundling harvester

A harvester and baler technology, which is applied in the field of intelligent rice-wheat combine harvesting and baler, can solve problems such as less technical integration, achieve basic recycling problems, high harvesting efficiency, and realize multi-functional automation control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following is attached with the manual figure 1 to attach Figure 7 The principles and features of the present invention are described in detail, and the content is only used to explain the present invention.

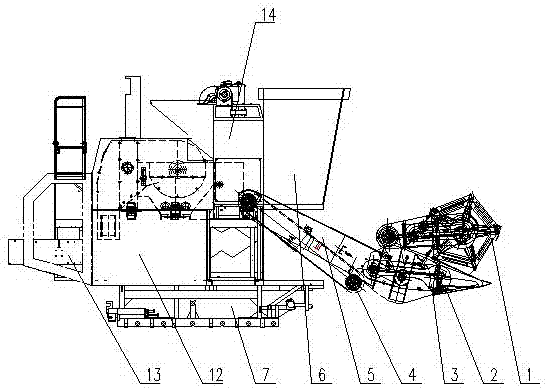

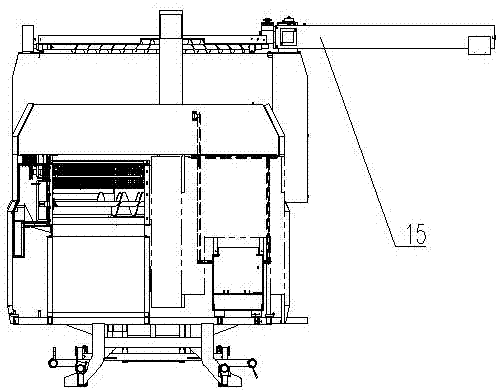

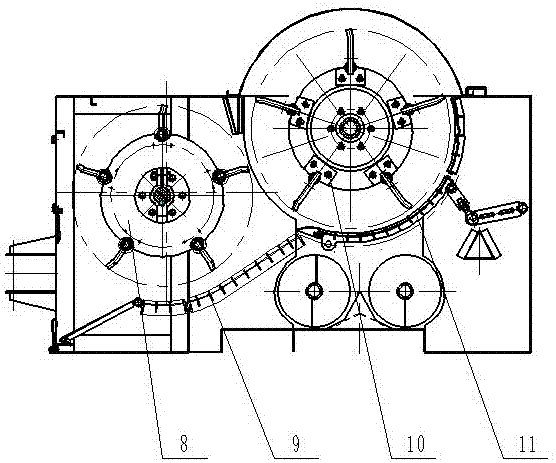

[0024] like figure 1 , 2 , 3, an intelligent rice-wheat combine harvester, including a reel 1, a cutter 2, a header auger 3, a conveyor chain rake 4, a bridge 5, a driver's cab 6, and a crawler chassis 7. Cutting flow drum 8, front concave plate 9, horizontal axial flow drum 10, rear concave plate 11, cleaning screen 12, bundling device 13, grain tank 14, grain unloading device 15; the reel 1, the The cutter 2 and the header auger 3 all belong to the header part of the harvester and are located at the front end of the harvester; the conveying chain rake 4 and the bridge 5 are located at the rear of the header; The cab 6 is located at the rear of the header; the crawler chassis 7 is located below the entire harvester; The threshing device that forms the ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com