Axial-flow cylinder of harvester

A harvester and axial flow technology, applied in agricultural machinery and implements, threshing equipment, applications, etc., can solve the problems of skewed drum, low torque, easy drilling of wheat straw, etc., and achieve increased structural strength, light screen load, crushing low rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

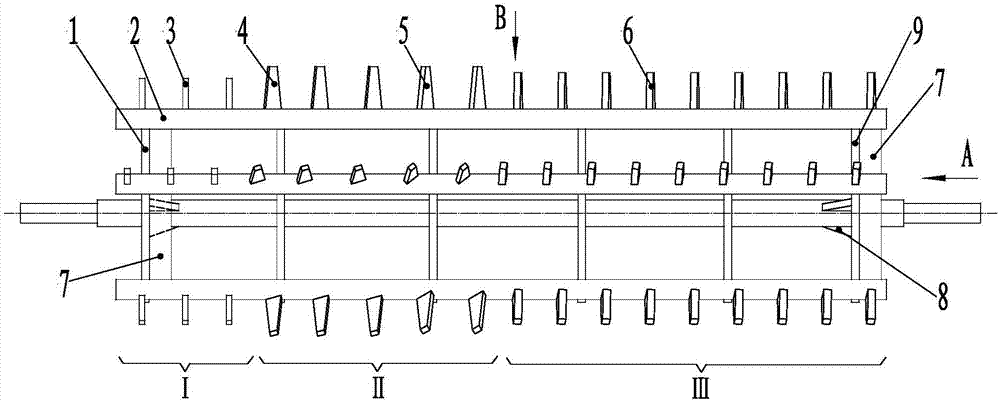

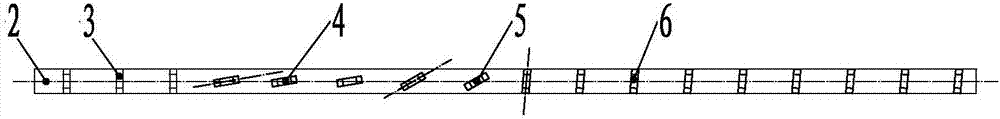

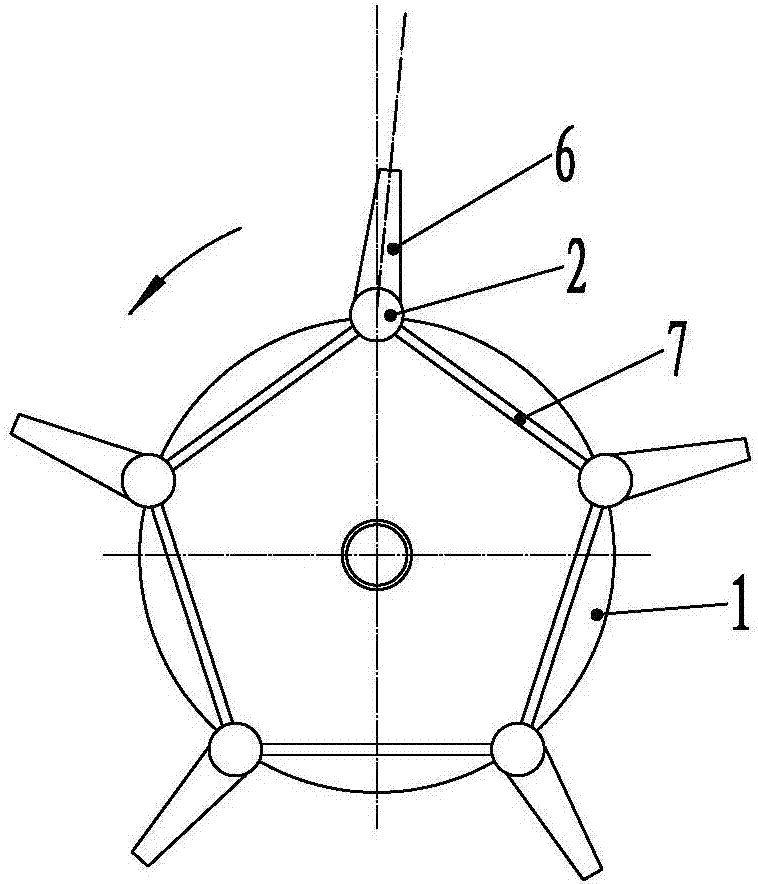

[0019] The axial flow drum on the harvester of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments:

[0020] figure 1 It is the structural representation of the axial flow drum on the harvester of the present invention, figure 2 Yes figure 1 B-direction view of middleware 2, image 3 Yes figure 1 A view from direction A. In the figure, the axial-flow drum on the harvester includes the main shaft, five racks 2 uniformly distributed around the main shaft and trapezoidal teeth arranged radially on the racks. The teeth are divided into discharge area I, separation area II and In the three sections of the feeding area III, five gear rods 2 are fixed on the circumference of the main shaft through a plurality of spaced support plates 1, and the right side of the two support plates 1 and 9 at the two ends is provided with a reinforcement plate 7, so The reinforcing plate 7 is arranged between two adjacent t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com