Pressure-driven impulse type pipeline washing brush

A pipeline flushing and pulse type technology, which is applied in the field of pressure-driven, pulse type pipeline flushing brushes, can solve the problems of repeated cleaning of the inner wall of low pressure pipelines, long length of spray guns and nozzles, and low passing rate of elbows, etc. High efficiency, improved cleaning efficiency, and less restrictive conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

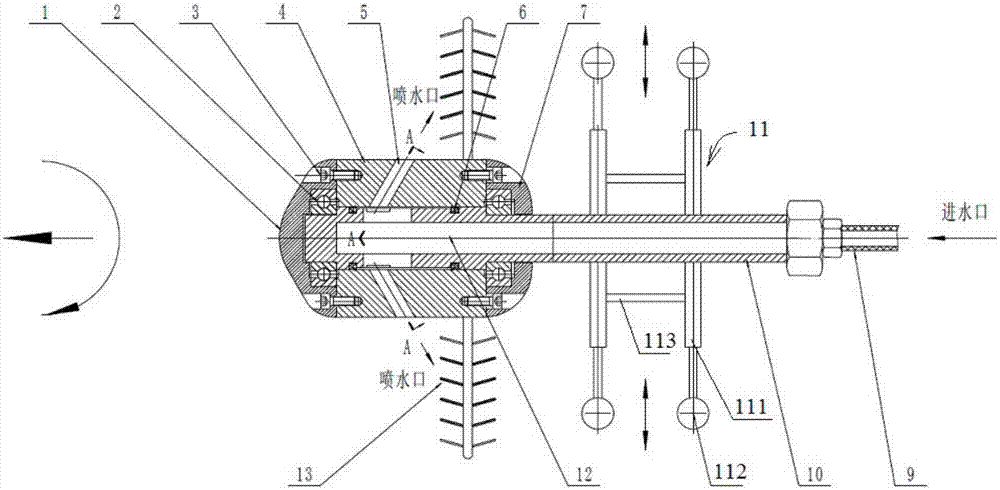

[0023] The technical solutions in the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the present invention.

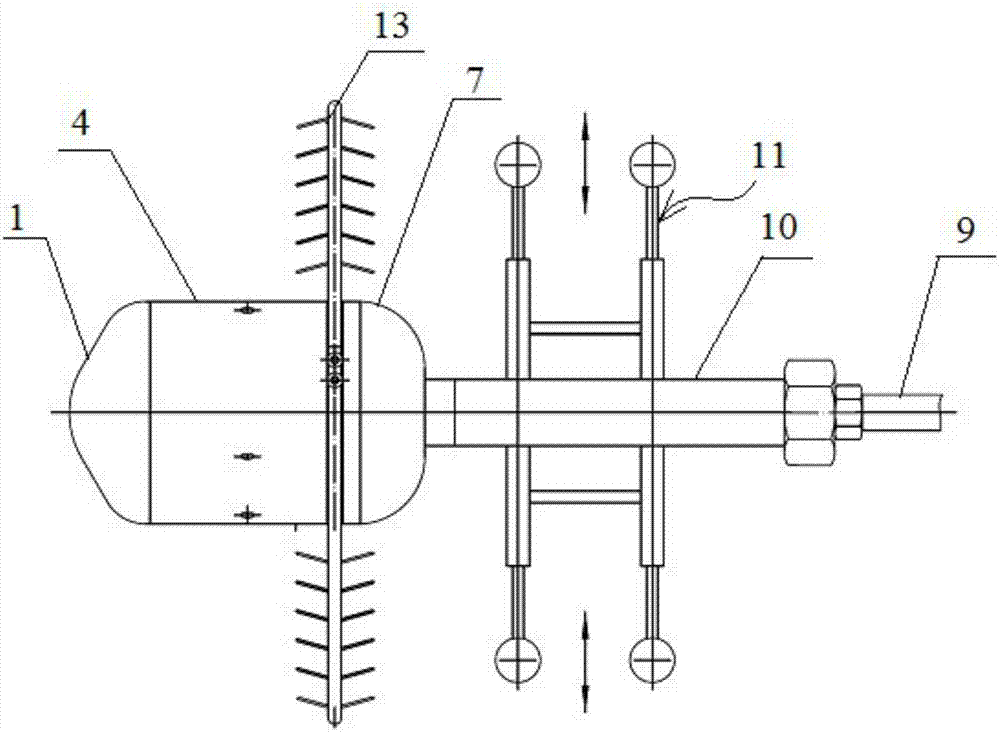

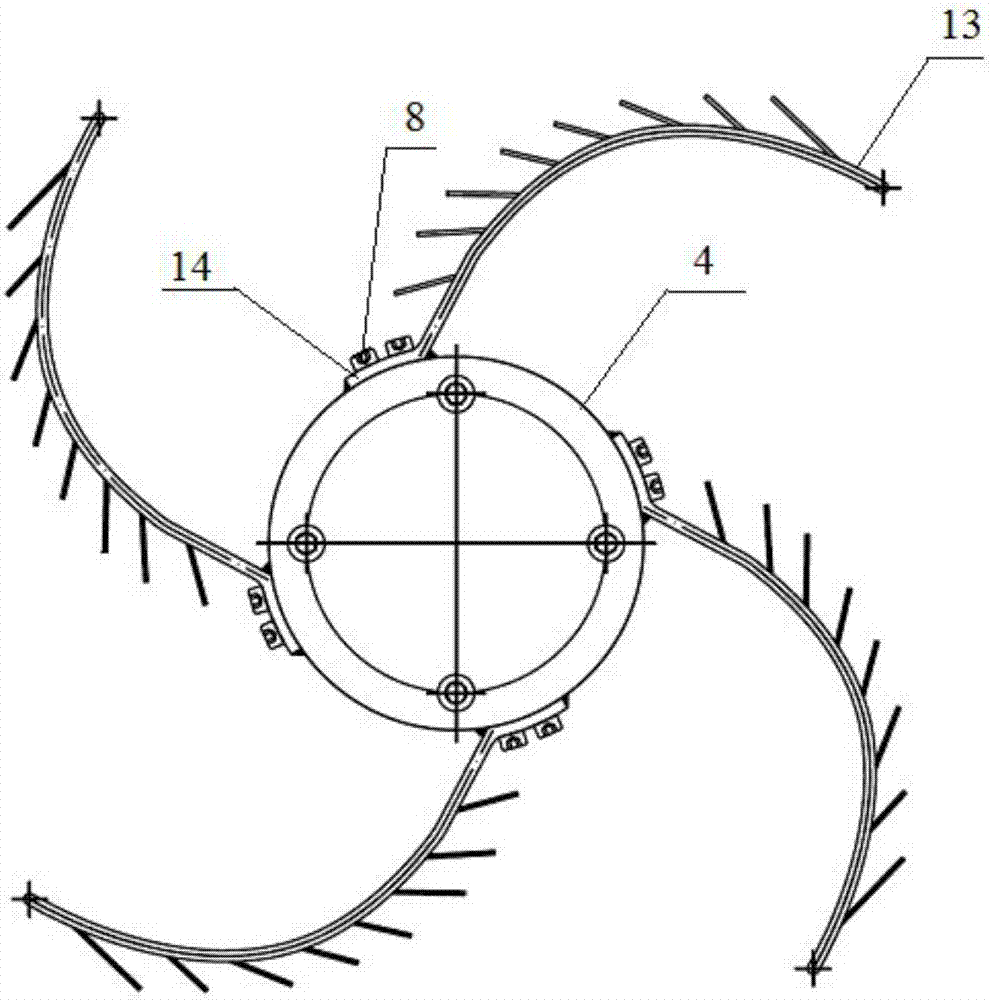

[0024] Please refer to Figure 1-3 One embodiment of the pressure-driven, pulse-type pipeline flushing brush of the present invention includes a rotating housing 4, a front end cover 1, a rear end cover 7, a central shaft 12, a pressure tube 10, an elastic brush 13, and a positioning wheel device 11.

[0025] The rotating housing 4 is a hollow cylinder with a certain wall thickness, and the front and rear ends are respectively sealed by the front end cover 1 and the rear end cover 7 . The top end of the front end cover 1 is arc-shaped, and can also be designed as spherical, spiral or chisel-shaped according to requirements, which can be used to remove large dirt during the advancement of the rotating housing 4, and through the countersunk head screw 3 and the rotating housing 4 connection, adopt the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com