High-precision device for removing flash groove burrs of wheel

A high-precision, cap opening technology, used in wheels, feeding devices, turning equipment, etc., can solve problems such as uneven deburring deviation and uneven chamfering, and achieve uneven deburring deviation and high-precision removal of cap openings. Burr, novel structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

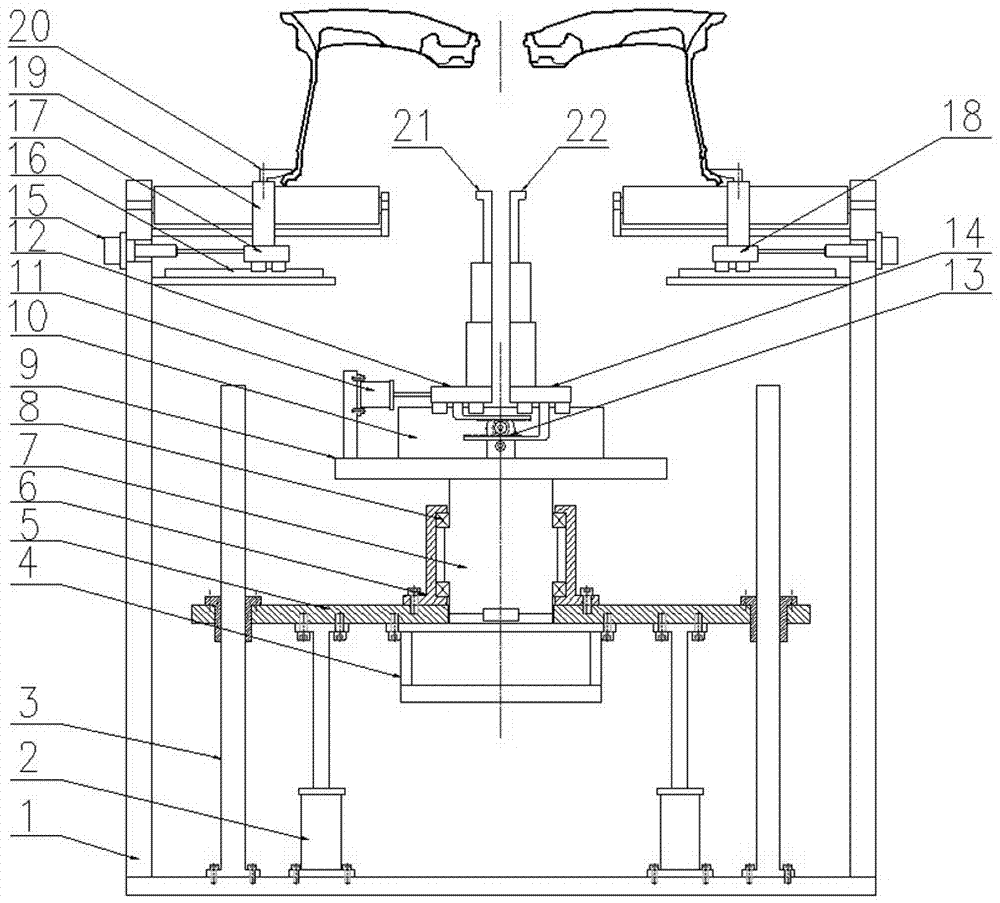

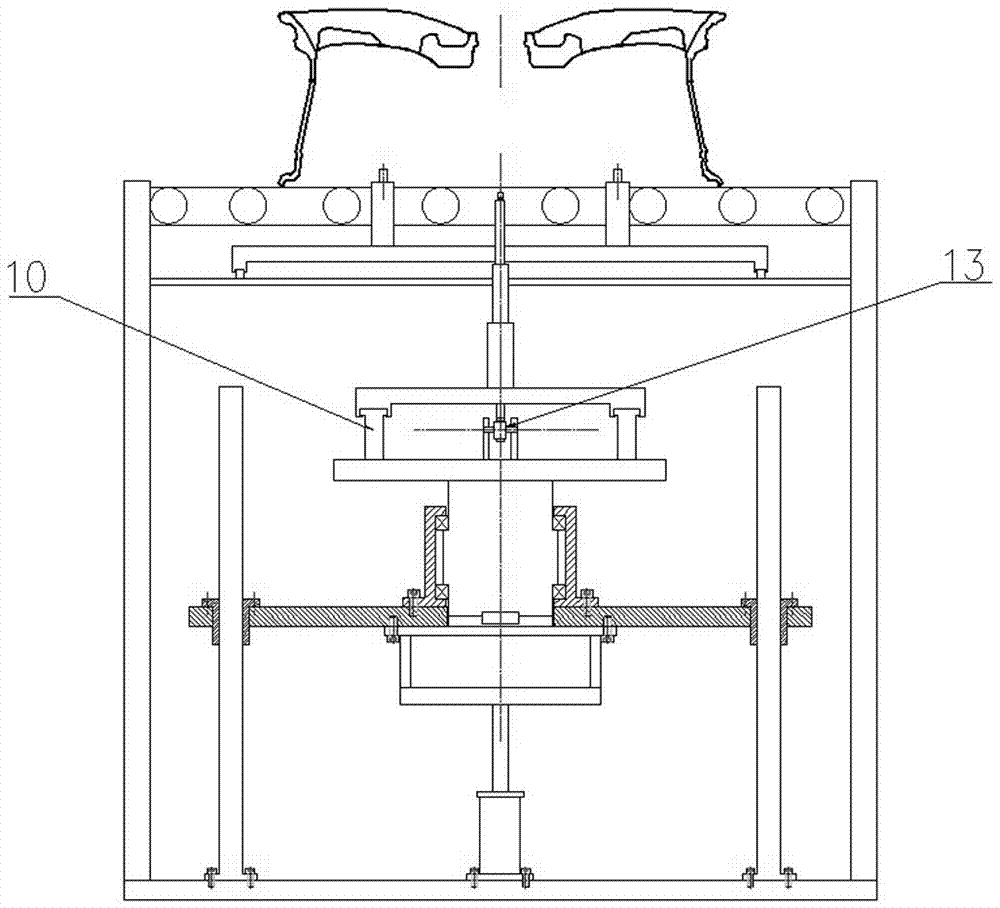

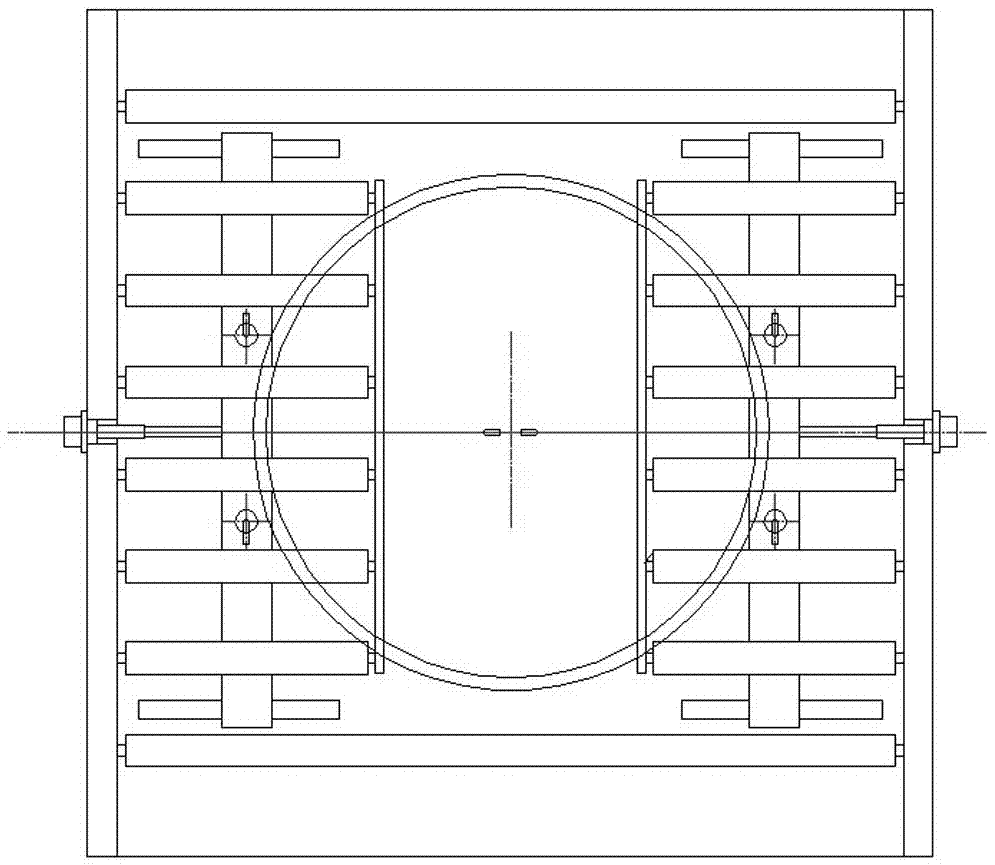

[0017] The details and working conditions of the specific device proposed by the present invention will be given below in conjunction with the description of the accompanying drawings.

[0018] A high-precision deburring device for the wheel cap, which consists of a frame 1, a jacking cylinder 2, a guide column 3, a servo motor 4, a lifting platform 5, a bearing seat 6, a shaft 7, a bearing 8, a rotary table 9, and an adjustment guide rail 10 , Adjusting cylinder 11, left sliding table 12, rack and pinion 13, right sliding table 14, pre-positioning cylinder 15, pre-positioning guide rail 16, slide plate Ⅰ 17, slide plate Ⅱ 18, pre-positioning column 19, corner cylinder pressure claw 20, left hairy bayonet 21 and right burr bayonet 22 form.

[0019] Four pre-positioning guide rails 16 are symmetrically installed on the frame 1, and slide plate I17 and slide plate II18 are installed on the pre-positioning guide rails 16 respectively, and both slide plate I17 and slide plate II18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com