Full-automatic assembly device of canister light spring

An assembly equipment, fully automatic technology, applied in the direction of metal processing equipment, metal processing, manufacturing tools, etc., can solve the problem of inability to meet the development trend of high efficiency, high quality and low cost, difficult to choose between processing output and processing cost, no operation mode automation equipment and other problems, to achieve the effect of simplified structure, labor saving and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

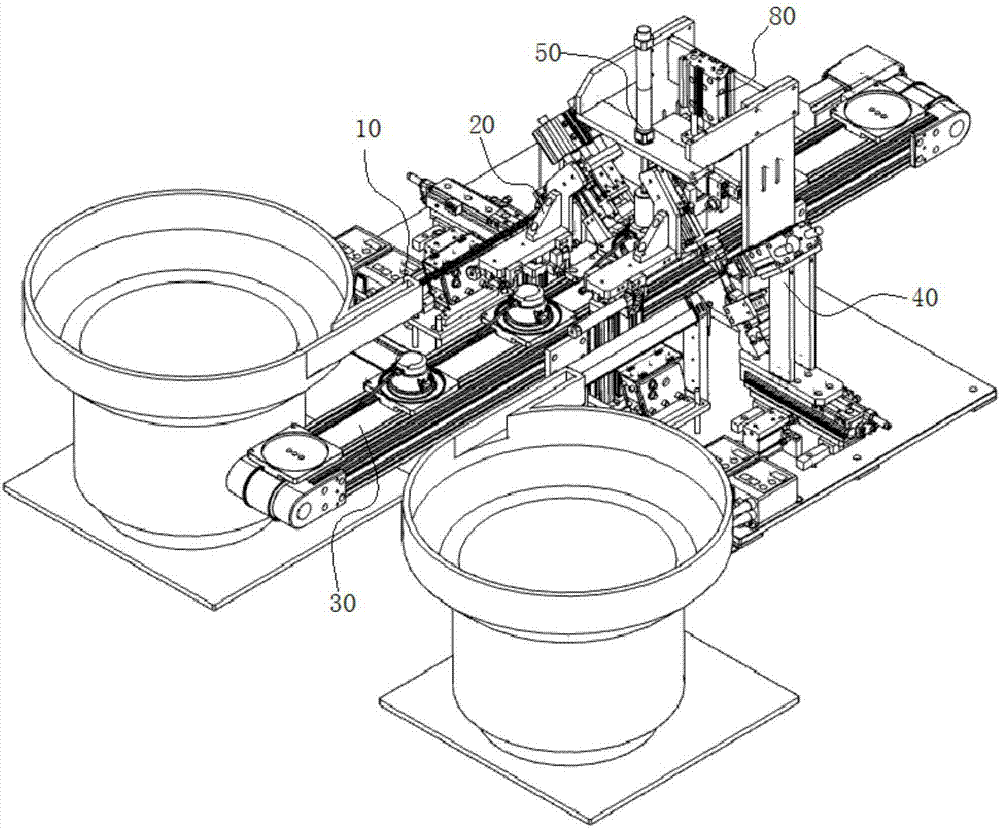

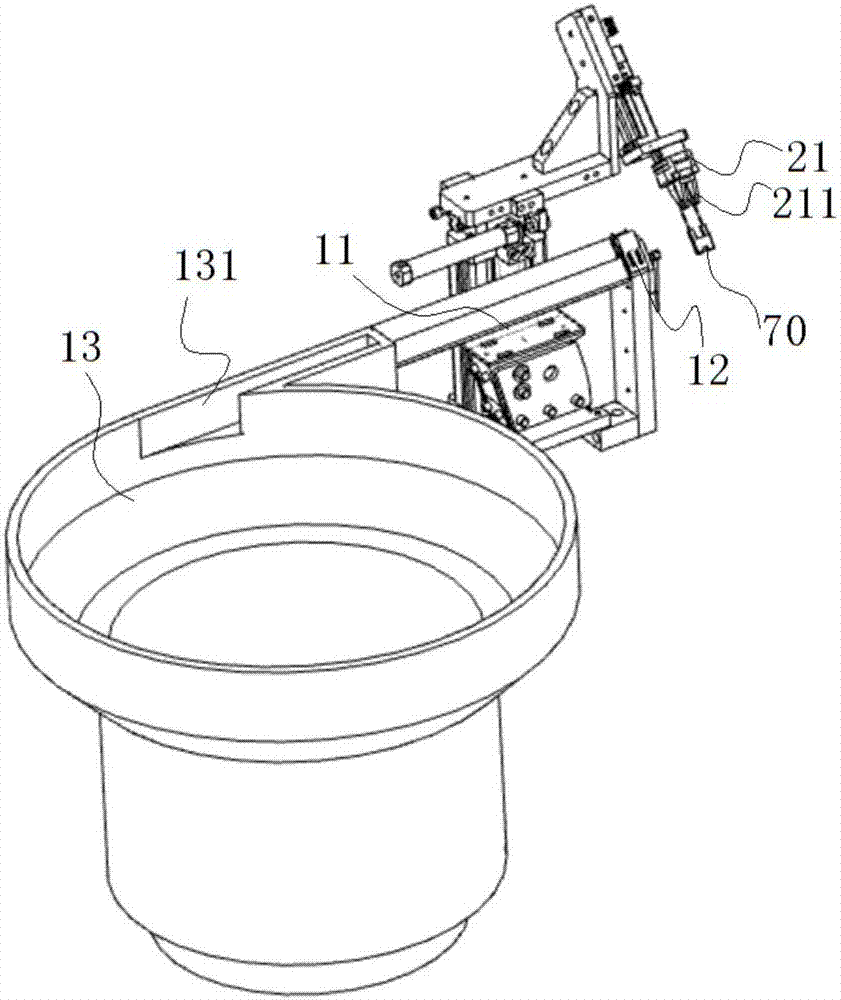

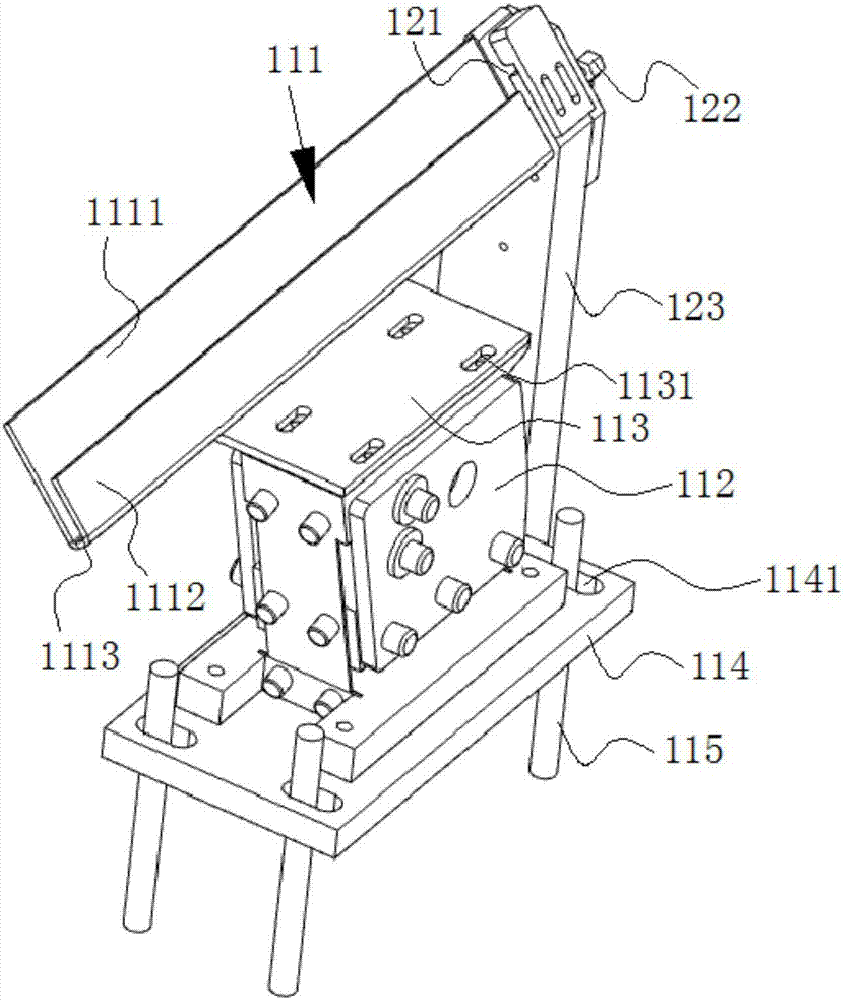

[0054] Embodiment 1: A kind of downlight spring automatic assembly equipment, such as Figure 1 to Figure 3-3 and Figure 5 to Figure 20 As shown, taking the direction of downlight transmission as the front, it includes spring automatic feeding device 10, spring automatic retrieving device 20, downlight automatic transmission device 30, spring left and right automatic clamping device 40, spring front and rear automatic shift fork device 80 and barrel The lamp automatic positioning and clamping device 50, the spring automatic feeding device, the spring automatic retrieving device and the spring left and right automatic clamping device are all located on the side of the downlight automatic conveying device, and the spring automatic retrieving device The device is located in front of the spring automatic feeding device, the spring left and right automatic clamping device is located in front of the spring automatic feeding and retrieving device, and the downlight automatic positio...

Embodiment 2

[0116] Embodiment 2: Similar in structure to Embodiment 1, the difference is: as Figure 4-1 to 4-3 as shown,

[0117] The structure of the feeding trough is: the height h22 of the second feeding plate is greater than the height h02 of the part below the coil of the spring, when feeding, the lower edge of the coil of the spring is hung on the second feeding plate The upper end of the spring and the tail end of the spring are not in contact with the bottom plate.

[0118] Preferably, the height h22 of the second feeding plate is 1-2 mm larger than the height h02 from the bottom surface of the spring to the lower tangent of the coil of the spring.

[0119] Preferably, the downlight spring generally has three specifications, and the height of the second feeding plate is greater than the height from the bottom surface of the spring of the largest specification to the lower tangent of the coil, because the spring hangs on the lower edge of the coil during the feeding process. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com