Quantitative concrete agitating device for construction machinery

A technology of mixing device and construction machinery, applied in cement mixing device, clay preparation device, mixing operation control device, etc., can solve problems such as insufficient mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

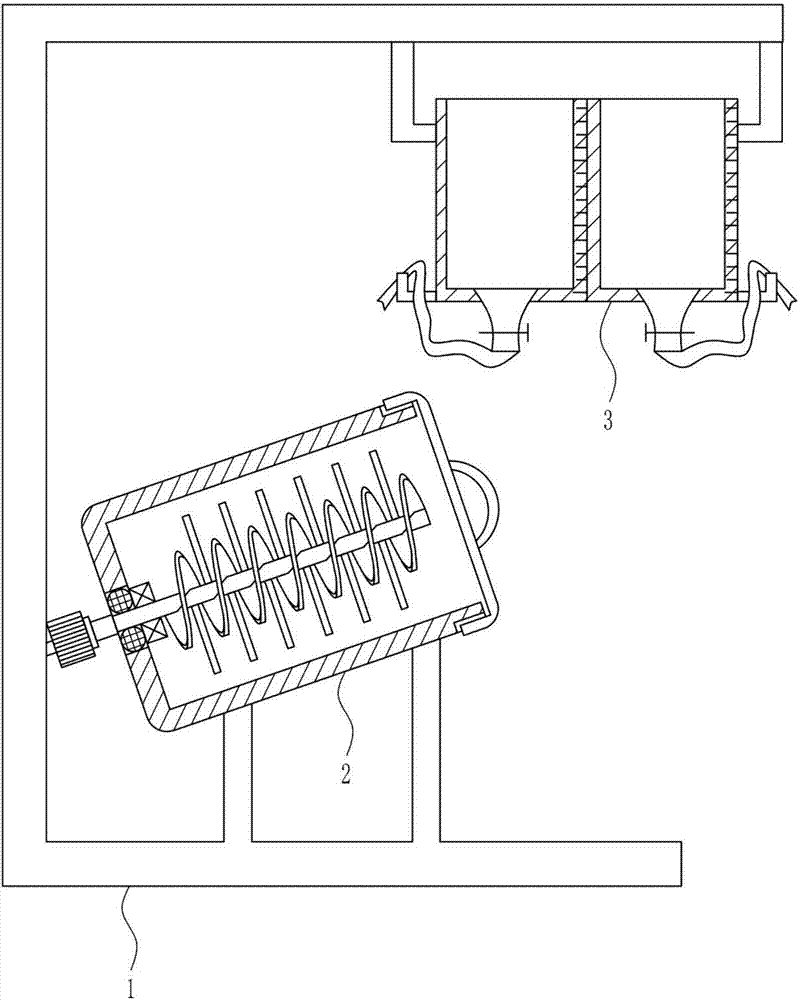

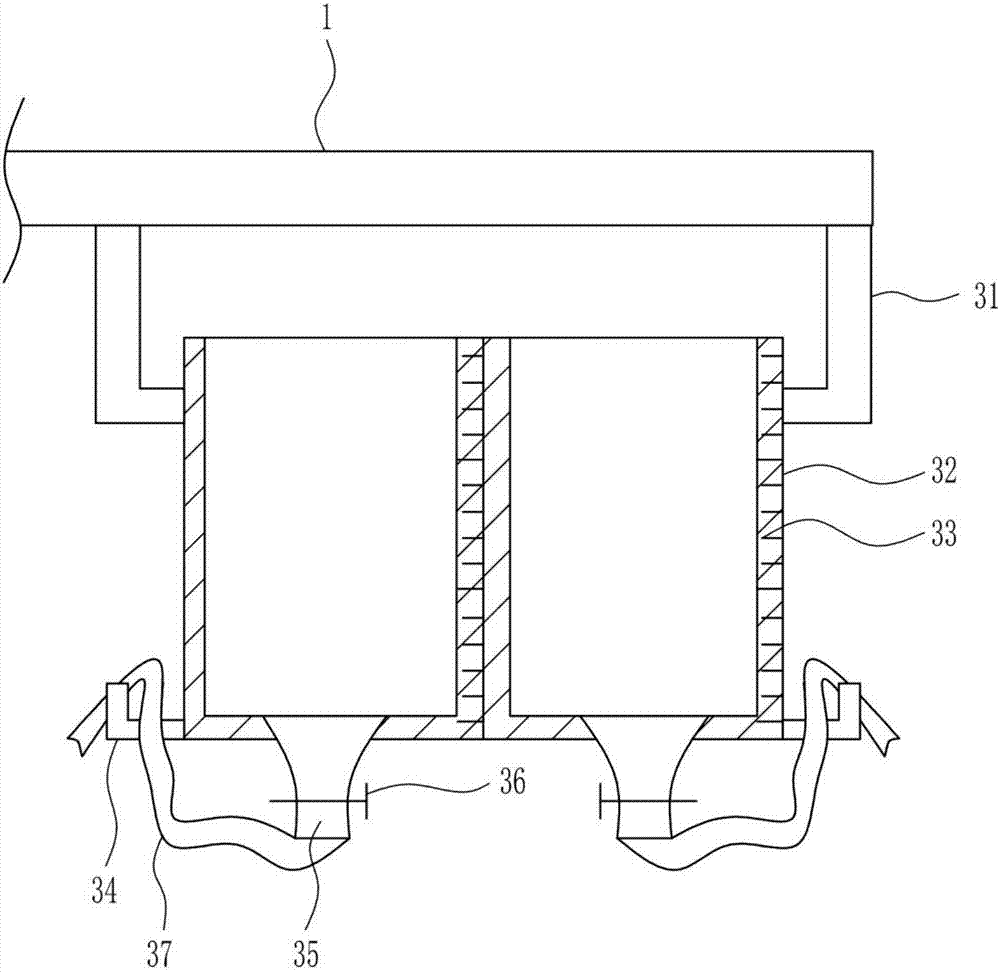

[0036] A concrete quantitative mixing device for construction machinery, such as Figure 1-7 As shown, it includes a support 1, a stirring mechanism 2 and a quantitative mechanism 3. The lower part of the support 1 is connected with a stirring mechanism 2, the upper part of the support 1 is connected with a quantitative mechanism 3, and the quantitative mechanism 3 is located at the upper right of the stirring mechanism 2.

Embodiment 2

[0038] A concrete quantitative mixing device for construction machinery, such as Figure 1-7 As shown, it includes a support 1, a stirring mechanism 2 and a quantitative mechanism 3. The lower part of the support 1 is connected with a stirring mechanism 2, the upper part of the support 1 is connected with a quantitative mechanism 3, and the quantitative mechanism 3 is located at the upper right of the stirring mechanism 2.

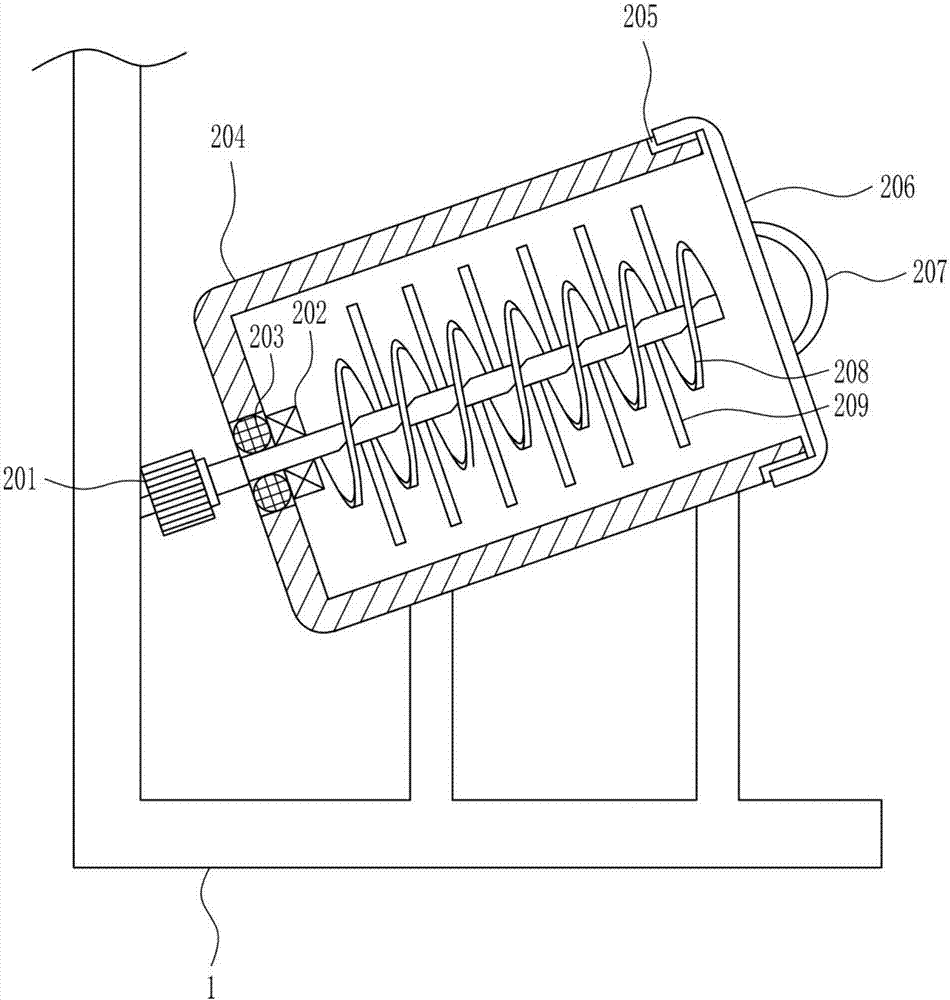

[0039] The stirring mechanism 2 includes a servo motor 201, a bearing seat 202, a sealing ring 203, a stirring box 204, a door 206, a handle 207, a stirring rod 208, and a first connecting rod 209. The top of the lower part of the support 1 is connected with a stirring box 204 for stirring The right side of the box 204 is provided with an annular threaded hole 205. The right side of the mixing box 204 is provided with a box door 206. The left side of the box door 206 is provided with an external thread that matches the annular threaded hole 205. The hole 205 ...

Embodiment 3

[0041] A concrete quantitative mixing device for construction machinery, such as Figure 1-7 As shown, it includes a support 1, a stirring mechanism 2 and a quantitative mechanism 3. The lower part of the support 1 is connected with a stirring mechanism 2, the upper part of the support 1 is connected with a quantitative mechanism 3, and the quantitative mechanism 3 is located at the upper right of the stirring mechanism 2.

[0042] The stirring mechanism 2 includes a servo motor 201, a bearing seat 202, a sealing ring 203, a stirring box 204, a door 206, a handle 207, a stirring rod 208, and a first connecting rod 209. The top of the lower part of the support 1 is connected with a stirring box 204 for stirring The right side of the box 204 is provided with an annular threaded hole 205. The right side of the mixing box 204 is provided with a box door 206. The left side of the box door 206 is provided with an external thread that matches the annular threaded hole 205. The hole 205 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com