Flexible bed-jig system for section construction of ship and construction method

A technology of segmented construction and tire frame, which is applied in the field of shipbuilding and construction tooling, can solve the problems of fixed adjustment range, low work efficiency, and lack of formulating a lattice partition plan for the tire frame, and achieves the effect of precise positioning and reduction of labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

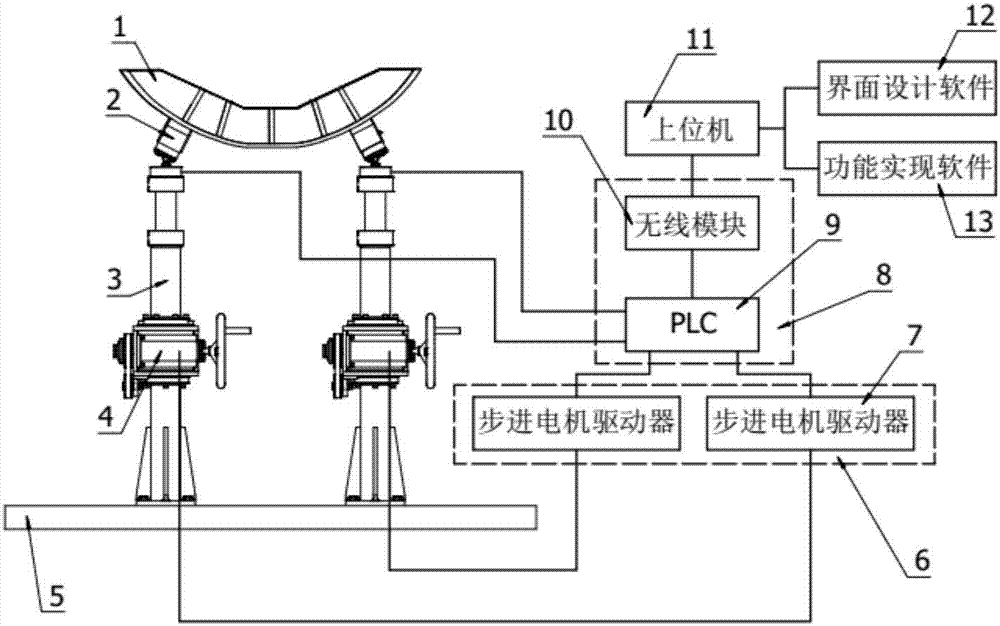

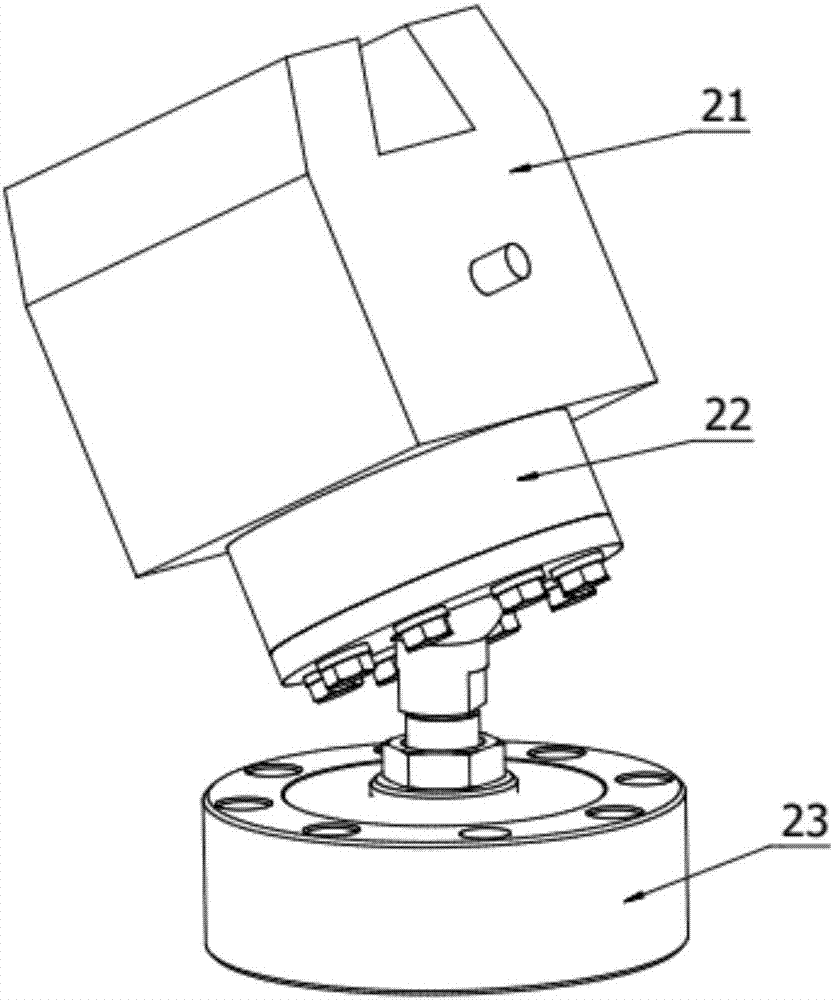

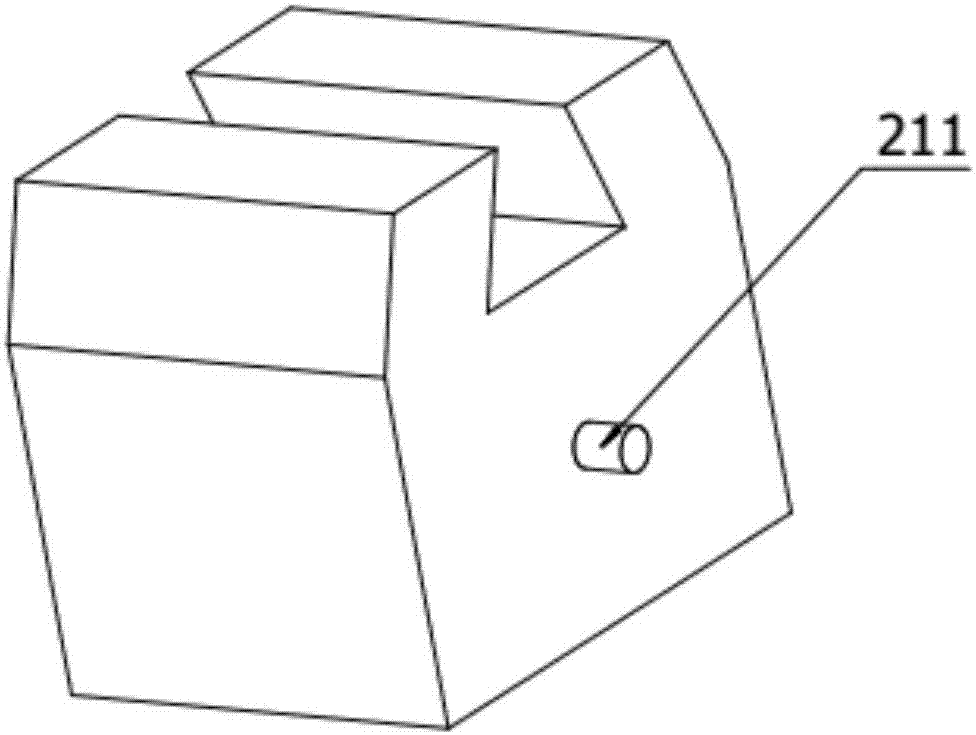

[0031] Such as Figure 1 to Figure 3 As shown, the flexible frame system for ship block construction of the present invention includes several construction support units, a driving mechanism 6, a PLC control system 8 and an upper computer 11 connected to the driving mechanism 6, and the construction support unit includes Two supporting and fixing mechanisms 2 for supporting ship sections and a flexible tire frame mechanism 3 connected to each supporting and fixing mechanism 2, the flexible tire frame mechanism 3 is connected with the driving mechanism 6, and the flexible tire frame mechanism 3 is a lifting mechanism, The flexible tire frame mechanism 3 is provided with a detachable external column 31, and the upper computer 11 and the PLC control system 8 adopt wireless module communication, and the upper computer 11 transmits the control amount to the PLC control syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com