Method for treating sludge of aquatic product processing factories

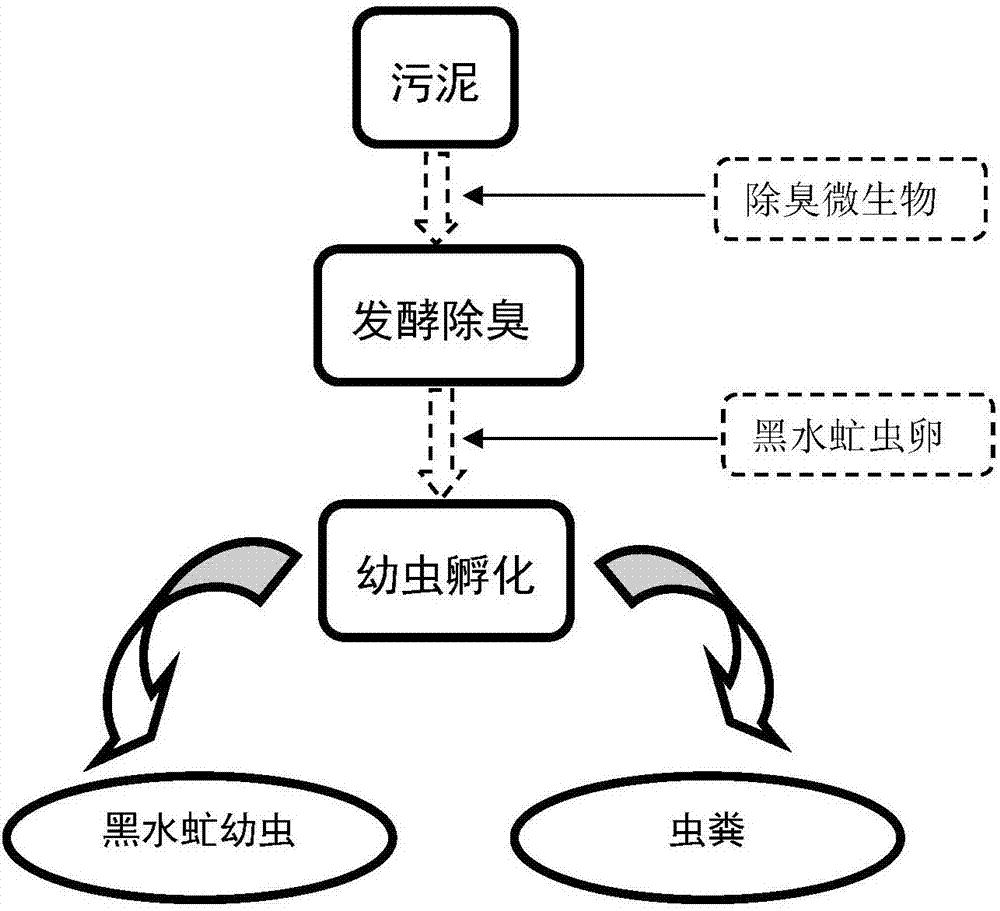

A processing plant and sludge technology, which is applied in the field of sludge treatment in aquatic product processing plants, can solve the problems of no economic benefit, low efficiency, and low organic matter content, and achieve the effect of less investment, excellent environment, and large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Collect 1 ton of sludge from the aquatic product processing plant in the sludge tank, add 1 / 1000th of the sludge mass urea and 15% of the sludge mass straw powder, and mix it into a mixture with a water content of about 70wt%. Then, pour into the prepared sludge (mixture) the mixed bacterial solution of yeast, lactic acid bacteria, and Bacillus subtilis, cover the sludge pool with a plastic film and seal it, and ferment for 10 days. After the fishy smell is eliminated, the sludge is taken out , paved into a plane with a thickness of about 10 cm, and then according to the added mass of 100 g / ton of sludge, black soldier fly eggs were inserted at 30°C, and after 10 days of treatment at 30°C, they hatched into black soldier fly larvae and obtained Insect manure, after sieving the black soldier fly larvae and insect manure with a vibrating sieve, the black soldier fly larvae are sent to a vacuum low-temperature dryer for drying, and the drying temperature is controlled at 75...

Embodiment 2

[0048] Collect 1 ton of sludge from the aquatic product processing plant in the sludge tank, add ammonium carbonate of 2 / 1000 of the sludge mass and 20% of the sludge mass of rice husk powder, and mix it into a water content of about 60wt%. Then, pour the EM bacterial liquid into the prepared sludge (mixture), cover the sludge pool with a plastic film and seal it, and ferment for 7 days. After the fishy smell is eliminated, take out the sludge and spread it into a thickness of about 5 cm Then, according to the added mass of 150 g / ton of sludge, the eggs of black soldier flies were inserted at 30°C. After 7 days of treatment at 30°C, black soldier fly larvae were hatched and feces were obtained. After the larvae and insect droppings are sieved with a vibrating sieve, the black soldier fly larvae are crushed into a slurry, and then EM bacteria are added to the resulting slurry, and fermented and stored in a sealed container; the insect droppings are matured and dried to make bioo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com