Bulletproof, anti-theft and energy-saving composite glass

A composite glass, outer glass technology, applied in the direction of preventing theft, parallel glass structure, fire doors, etc., can solve the problems of affecting light transmittance, easy wear of bulletproof film, damage of anti-theft net, etc., to improve thermal insulation or thermal insulation performance , Good light transmission performance, the effect of reducing the volume decibel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

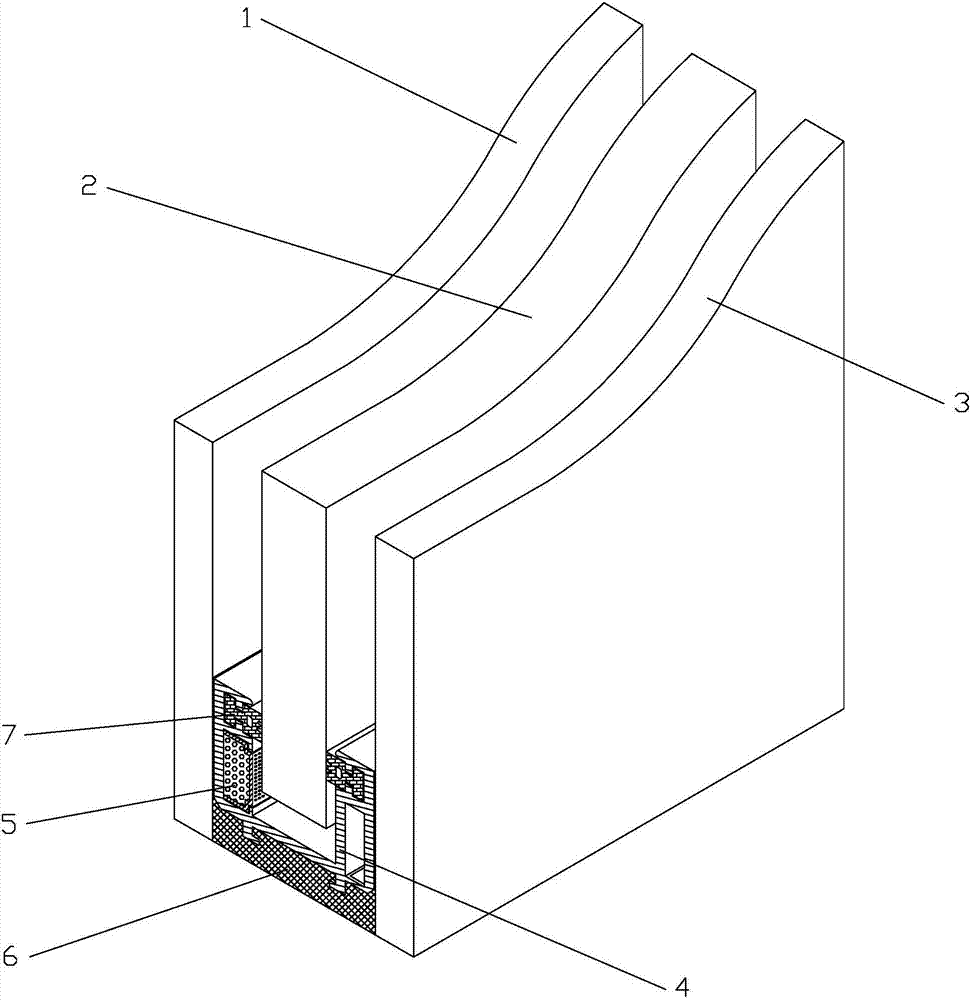

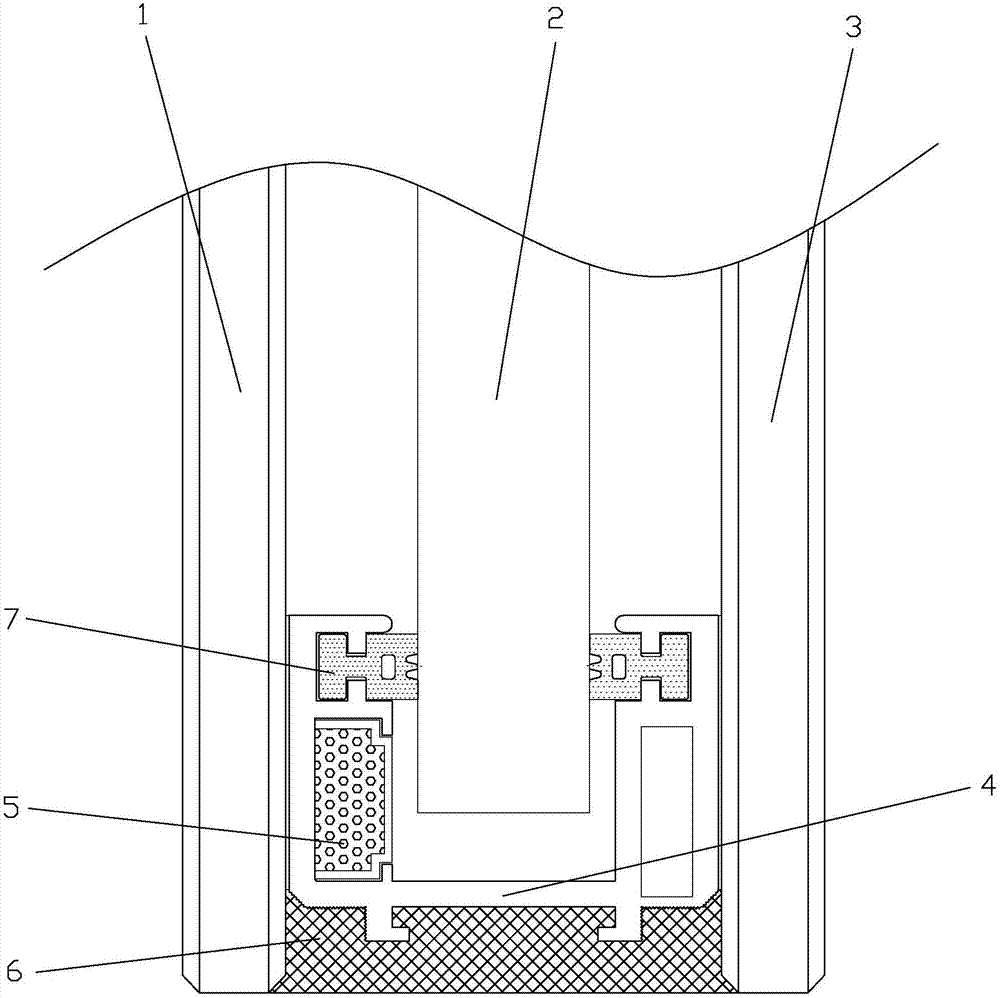

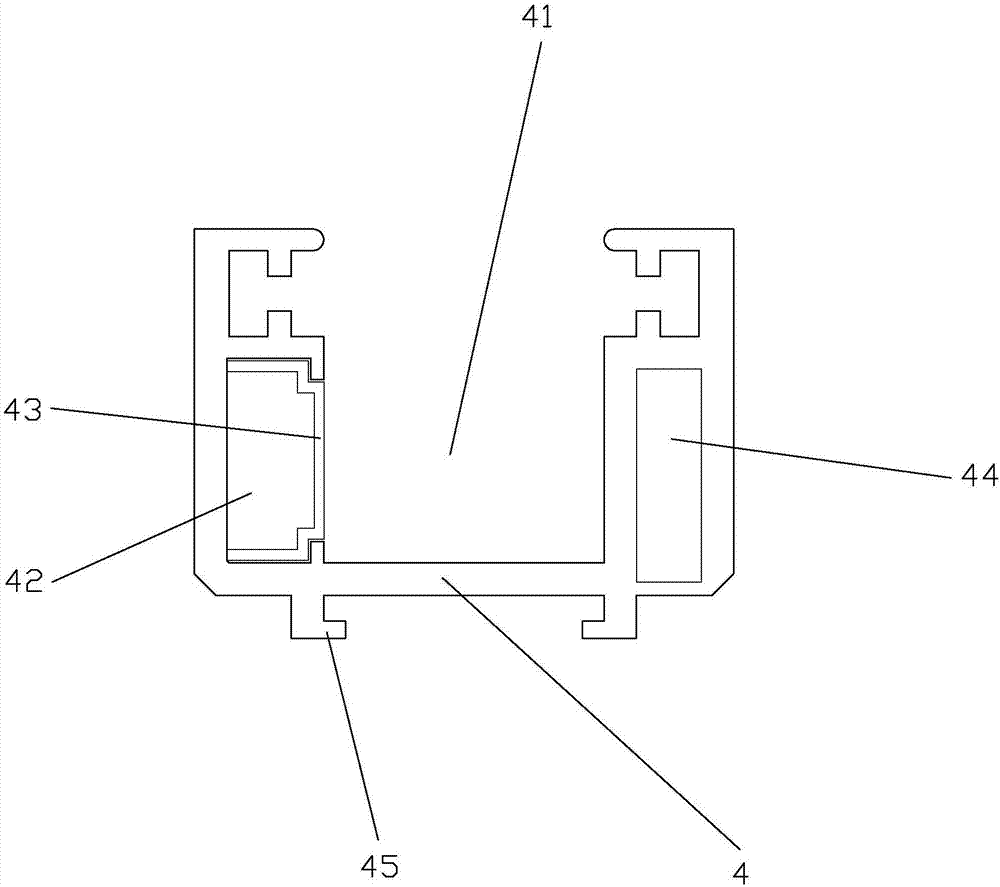

[0024] refer to Figure 1 ~ Figure 3 , a bullet-proof, anti-theft, energy-saving composite glass, including an installation frame 4 and an inner glass 1 connected to the installation frame 4, a bulletproof endurance film 2, and an outer glass 3, and the inner glass 1 and the outer glass are divided into three parts The two sides of the installation frame 4 are usually bonded with butyl glue. The outer surface of the installation frame 4 and the inner glass 1 and outer glass 3 are covered with sealant 6, which can not only serve as a sealing structure but also increase the structural strength and stability. The middle part of the installation frame 4 is provided with a groove 41, and the edge of the bulletproof film 2 is connected to the groove 41. Since the thermal expansion of the bulletproof film 2 far exceeds that of the inner glass 1 and the outer glass 3, the groove 41 There is a reserved space between the bulletproof and durable film 2 for the expansion of the bulletproo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com