Miniature hydraulic drive system used for ankle joint artificial limb

A driving system and ankle joint technology, applied in fluid pressure actuation devices, accumulator devices, artificial legs, etc., can solve problems such as slow response speed and insufficient output torque, so as to avoid start-stop and commutation, Reduced power consumption, the effect of reducing peak power requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

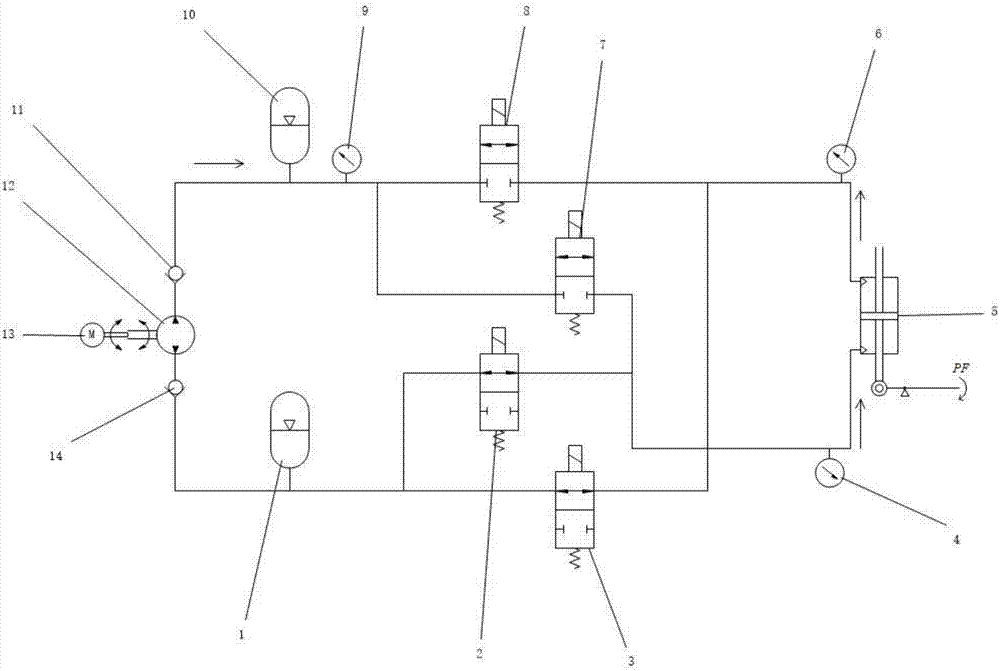

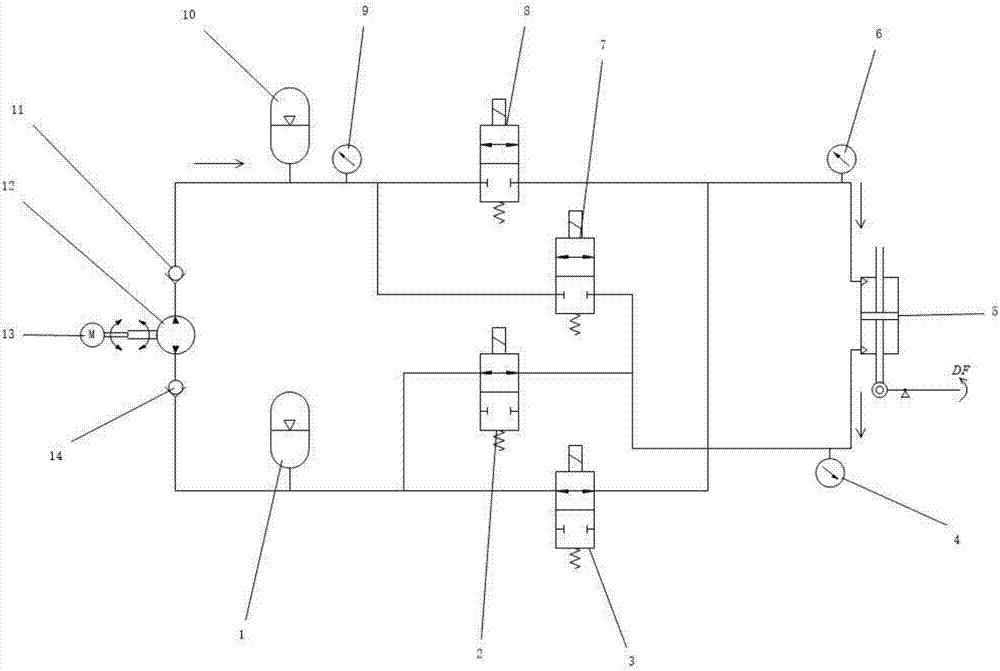

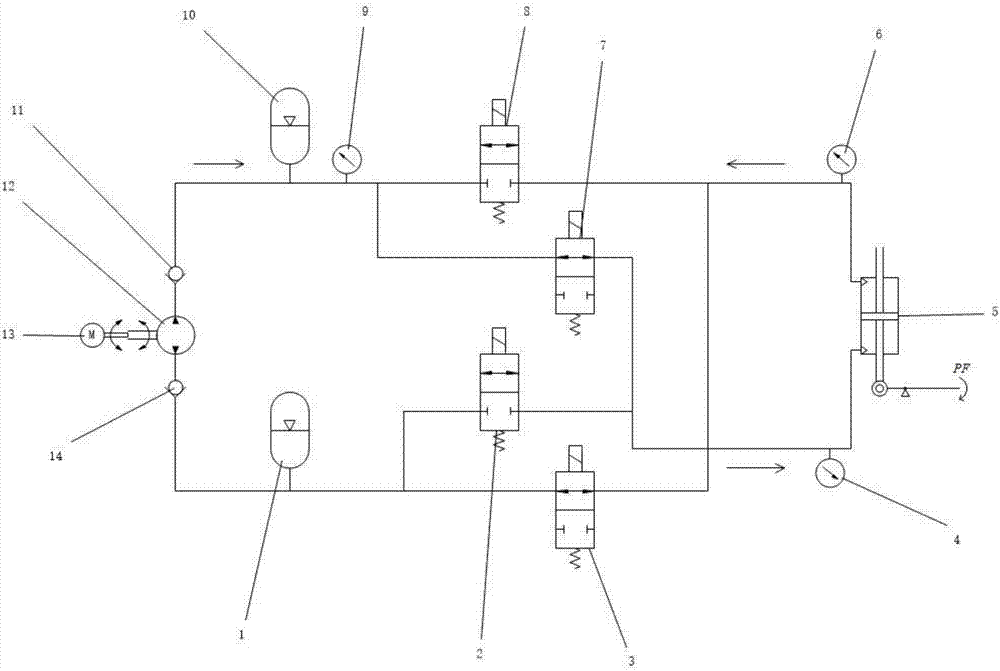

[0029] In the present invention, the hydraulic pump 12 adopts the electric motor 13 (brushless DC motor) to control the plunger pump, and the oil outlet of the hydraulic pump 12 passes through the first one-way valve 11 and the first accumulator 10, the first pressure sensor 9, the first The two normally closed switch valves 8 and the first normally closed switch valve 7 are connected; the oil inlet of the hydraulic pump 12 is connected with the second accumulator 1, the first normally open switch valve 2 and the second normally open switch valve 1 through the second check valve 14. Open the switch valve 3 to connect. The upper rod cavity of the double rod hydraulic cylinder 5 is connected with the second pressure sensor 6 , the second normally closed switch valve 8 and the second normally open switch valve 3 . The lower rod chamber of the double-rod hydraulic cylinder 5 is connected with the third pressure sensor 4 , the first normally closed switch valve 7 and the first norm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com