Gearing-down device and method for industrial fan

A deceleration transmission and fan technology, which is applied to the transmission device, transmission device parts, gear transmission device, etc., can solve the problems of increasing the energy consumption of the power device, loss of power mechanism mechanical wear, large area of rotation and agitation, and reducing the service life of the fan. Achieve the effect of reducing oil leakage, saving energy consumption and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

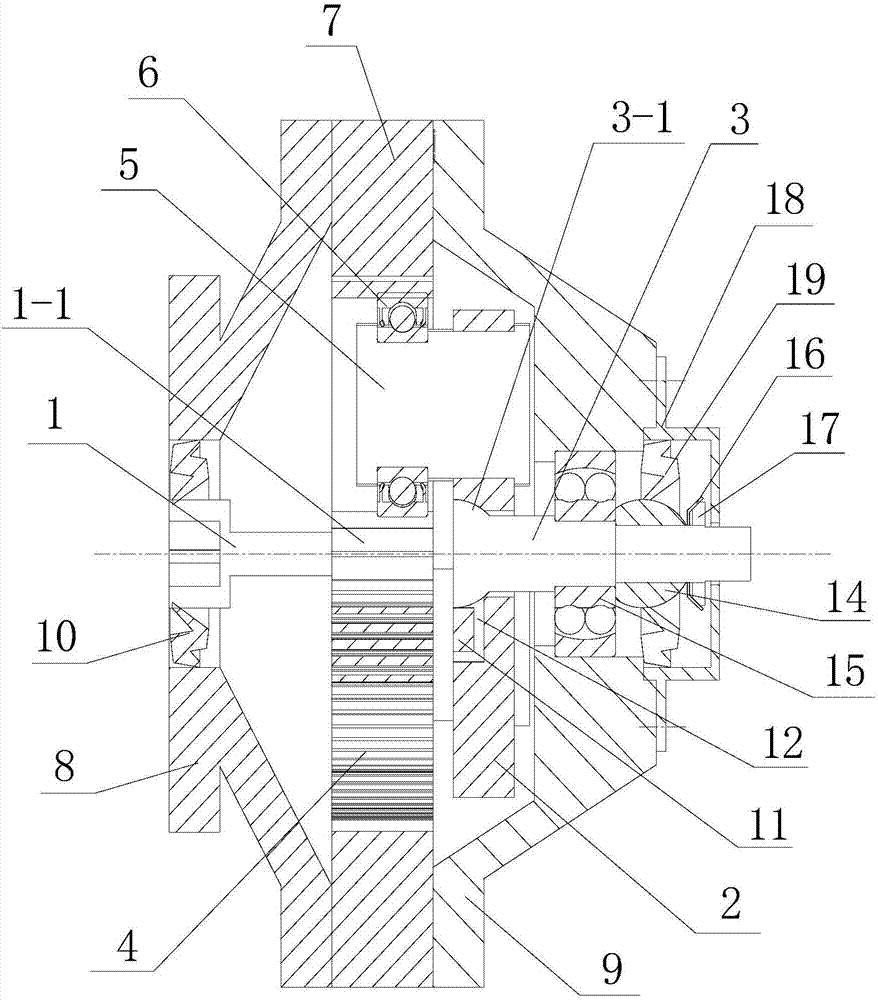

[0027] In this embodiment, a kind of deceleration transmission device for industrial fans, such as figure 2 As shown, it includes input shaft 1, planetary gear assembly, transmission disc 2 and output shaft 3. One end of the input shaft is connected to an external motor, the other end of the input shaft is connected to the transmission disc through the planetary gear assembly, and one end of the output shaft has a spherical connection surface 3-1 , and connect with the transmission disc through the spherical connection surface. In this structure, the traditional single-shaft output transmission structure is changed to a multi-stage output transmission structure, and the planetary gear assembly and the transmission disc are used for transmission in the middle, which can effectively improve the radial torque while reducing the radial torsion caused by the excessively long transmission shaft. The balance of the transmission output keeps the natural rotating surface of the power ...

Embodiment 2

[0034] In this embodiment, a deceleration transmission method for industrial fans is realized through the device described in Embodiment 1, specifically: after the external motor of the deceleration transmission device outputs power to the input shaft, it first decelerates through the planetary gear assembly, and the planetary gear assembly drives the transmission The disc rotates, and then the output shaft is connected with the transmission disc by means of a spherical connection surface, and the output shaft is driven by the rotating disc to output power.

[0035] Wherein, when the planetary gear assembly is decelerating, the specific process is as follows:

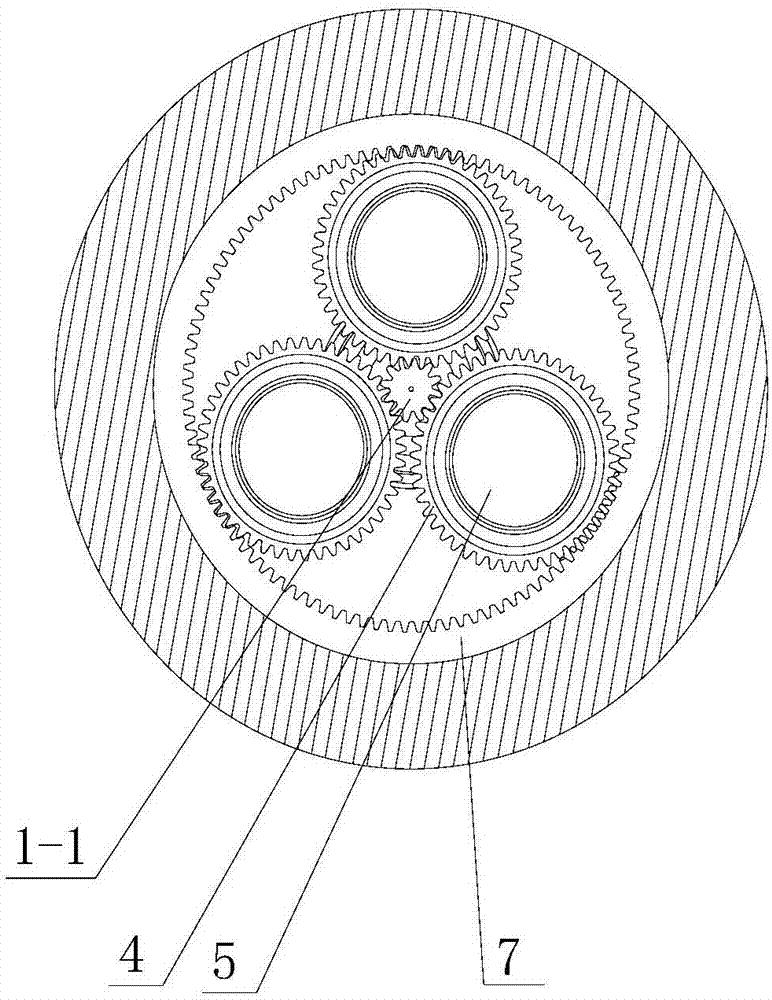

[0036] Each planetary gear in the planetary gear assembly rotates around the gear shaft section of the input shaft, and each planetary gear is limited in the inner gear when rotating; each planetary gear is provided with a corresponding planetary shaft, and is connected to the planetary shaft through the first bearing, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com