Bomb heat refrigerating cycle method driven by low-grade heat and system thereof

A refrigeration cycle and low-grade heat technology, which is applied in the direction of refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of no help, large driving force of the system, etc., to avoid fluid leakage, simple system structure, and simplified system design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0044] The present invention relates to shape memory alloys (referred to as memory alloys) that provide stress and strain characteristics when they change from martensite to austenite under thermal drive, and when memory alloys change from austenite to martensite phase under stress drive Variable exothermic properties. In the memory alloy, there are at least two crystal structures (phases), that is, a high temperature phase (austenite) and a low temperature phase (martensite) at zero stress.

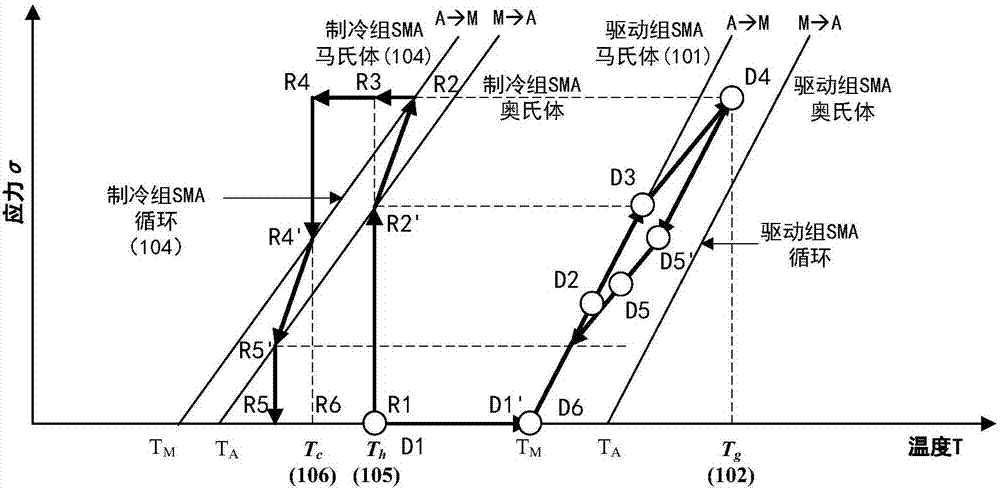

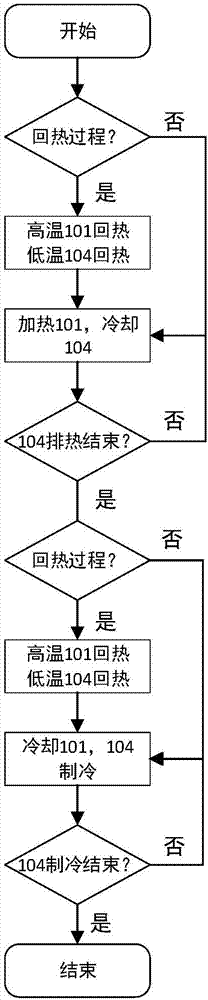

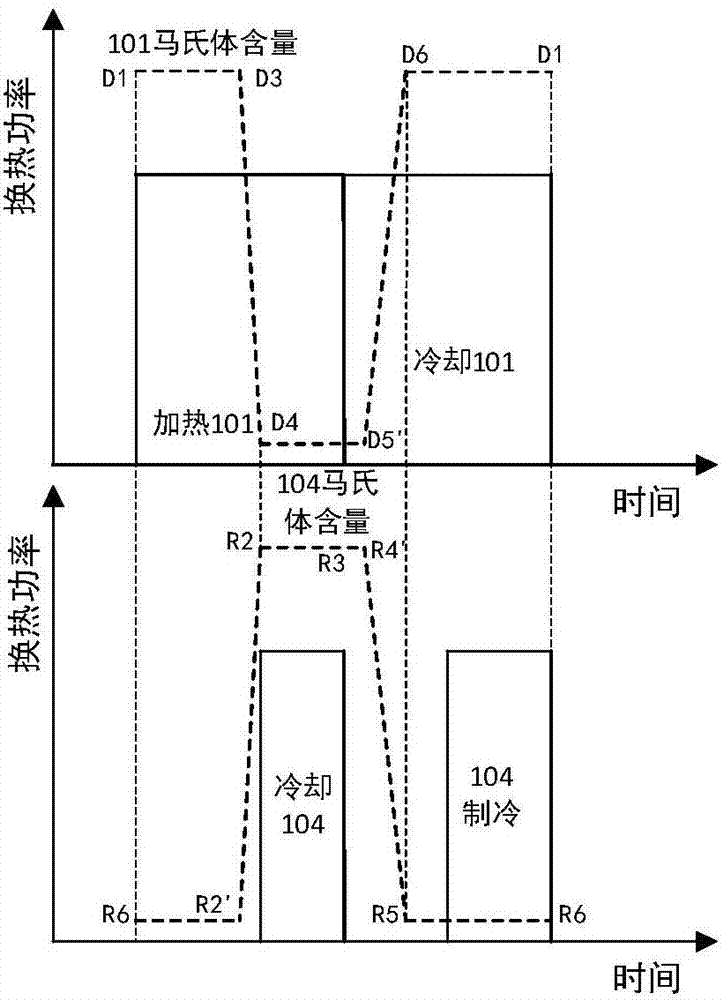

[0045] figure 1 The fundamentals of the heat-driven elastothermic refrigeration cycle approach are described. In order to facilitate the understanding of the principle, Figure 2A , Figure 2B , Figure 2C The basic process of the cycle method is described more vividly through the cycle flow chart, Figure 3A , Figure 3B Provides a design scheme fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com