Anti-broken manufacturing method of capacitance type touch display screen FPC (flexible printed circuit)

A technology of capacitive touch and manufacturing method, which is applied in the direction of printed circuit manufacturing, electrical components, printed circuits, etc., can solve the problems of easy bruising, broken FPC pad pins, product scrapping, etc., and achieves the goal of preventing being bruised Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

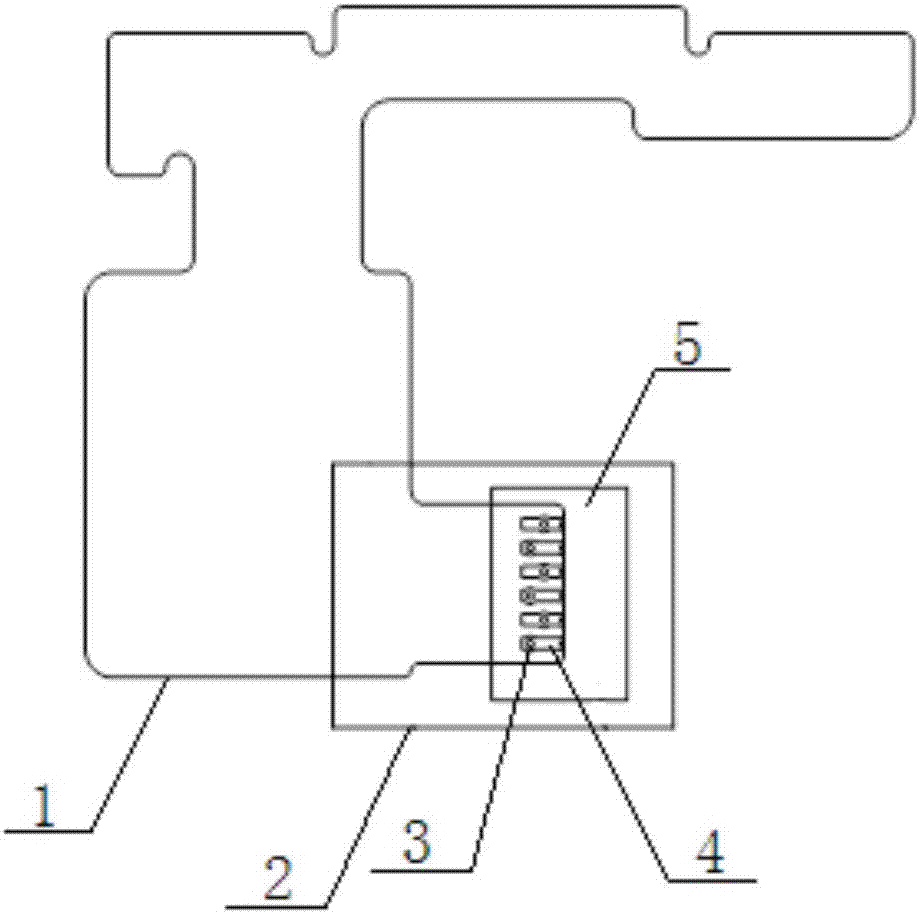

[0022] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

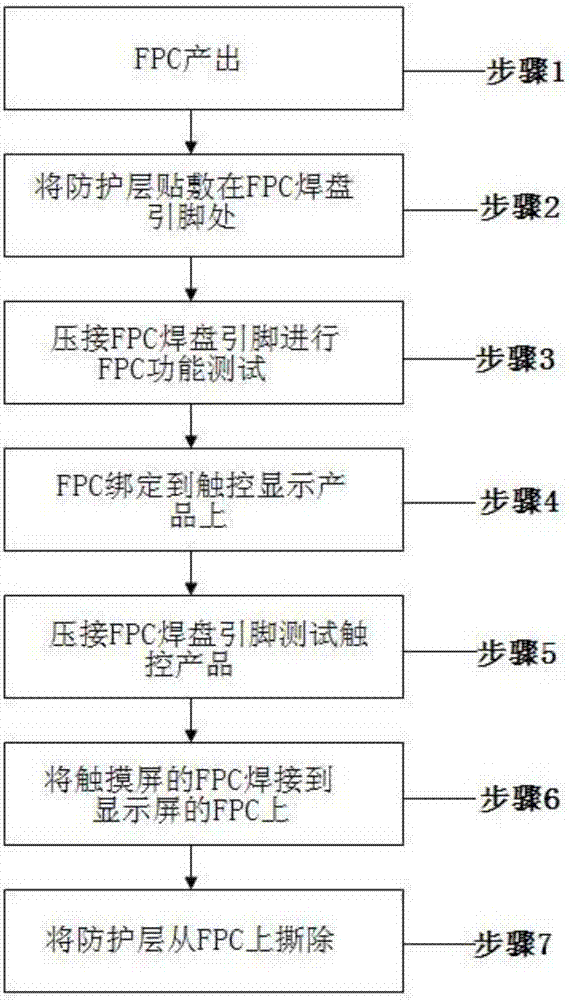

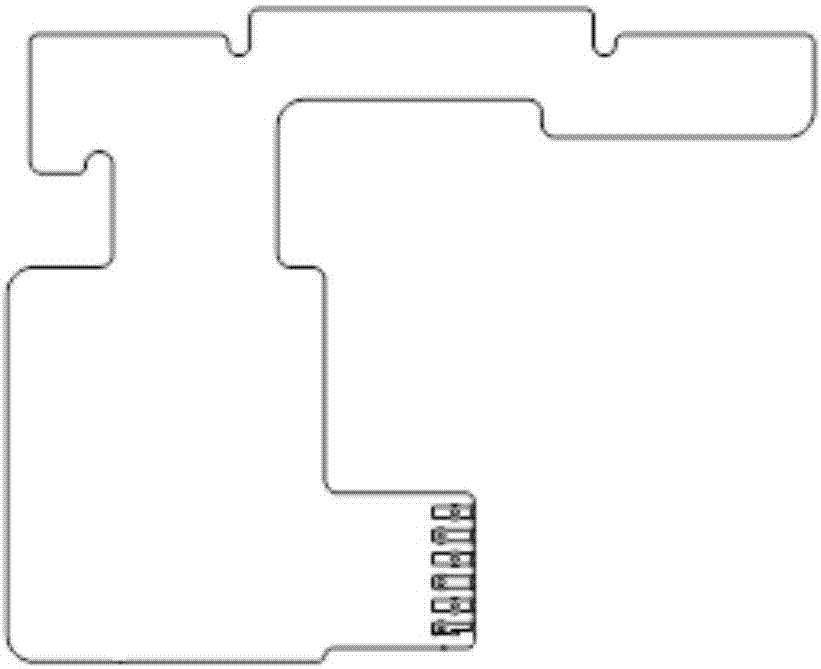

[0023] Such as figure 1 with 2 As shown, what is described in the embodiment of the present invention is a method for making a capacitive touch screen FPC to prevent damage. In the production process of the group, the FPC used in the present invention is one of the components of the capacitive touch display screen, and the production has been completed, mainly in order to avoid the problem of breaking the FPC, which is a component of the capacitive touch display screen. The method includes the following steps:

[0024] Step 1. Make FPC. FPC finished products are produced through cutting, drilling, copper sinking, electroplating, film sticking, exposure, development and other processes. The production process of FPC finished products is produced by existing technical means.

[0025] Step 2. Attach the protective layer 2 with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com