Laminated slab prefabricated part parameter modeling production method

A technology of parametric modeling and prefabricated components, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of poor precision, difficult coordination, low efficiency, etc., to achieve accurate information, increase speed, and ensure The effect of image quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

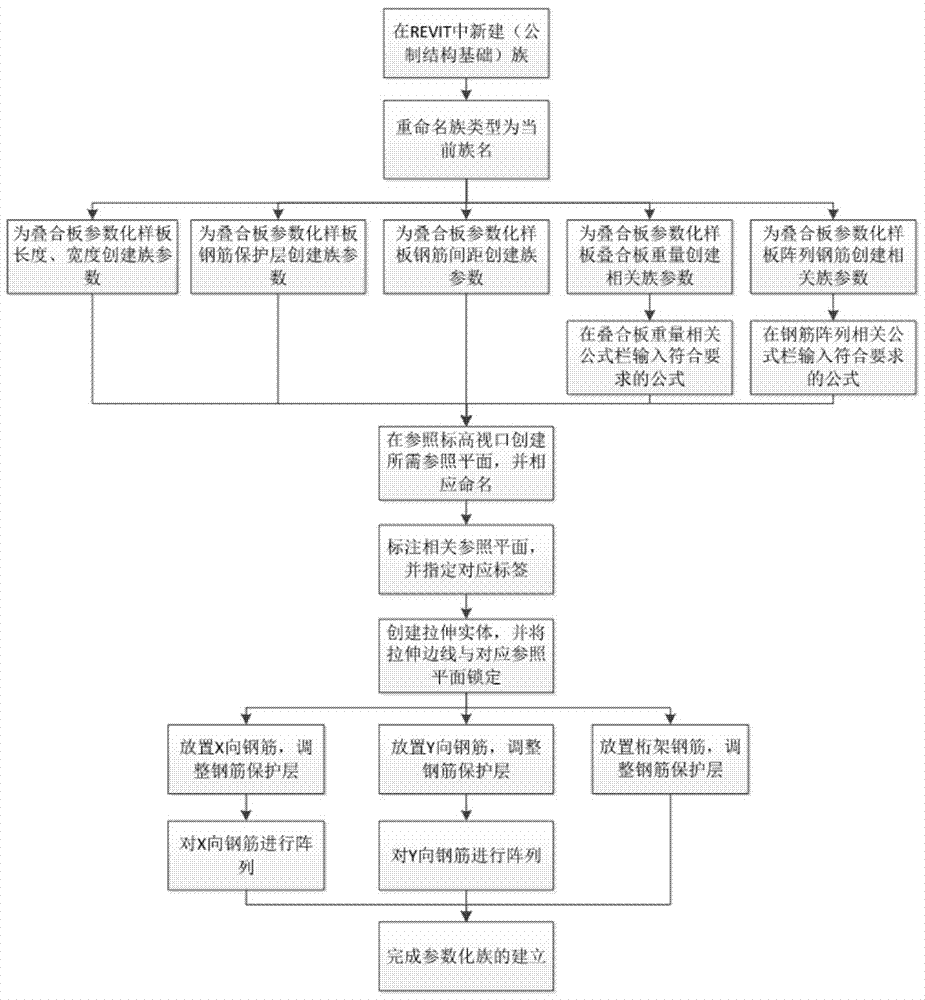

[0030] A parametric modeling production method for prefabricated composite panels, the process of which is as follows: first, a parametric model of a composite panel is established; then, construction drawings are directly produced from this set of completely correct parametric models. , increase or decrease, adjust the number of planes, elevations, sections and details on the drawings at any time, and can draw out specific details, so that the production unit can better understand the drawing information; finally, the production is carried out in the factory according to the drawn construction drawings.

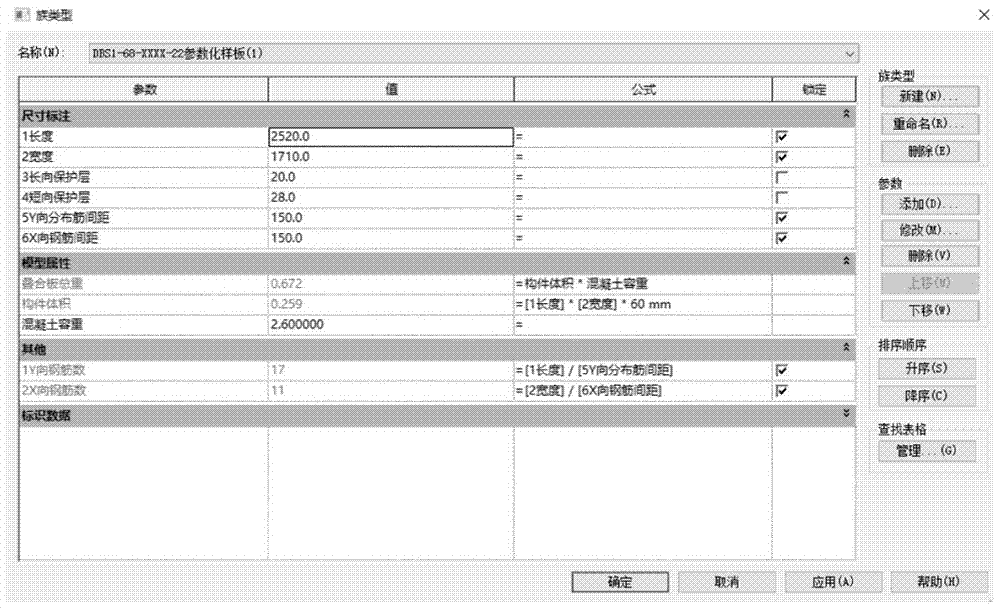

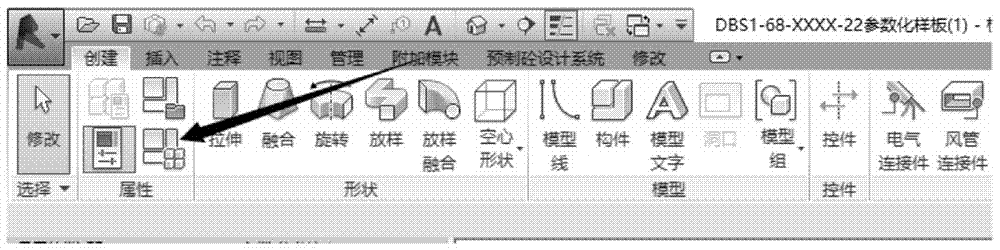

[0031] The parameterized model of the laminated board can realize parameter driving, and the logic of parameter driving is: first, set the family parameter superposed board family parameter interface as follows: figure 1 shown), that is, the drive parameters involved in the parameterized drive. Then create a reference plane, mark the reference plane, define and label the fam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com