A transmission line deicing device

A technology of transmission lines and longitudinal beams, which is applied in the installation of cables, overhead installations, electrical components, etc., and can solve problems such as broken wires, accidental injuries, and grounding short circuits, so as to avoid excessive bending, ensure safety, and avoid being damaged. damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

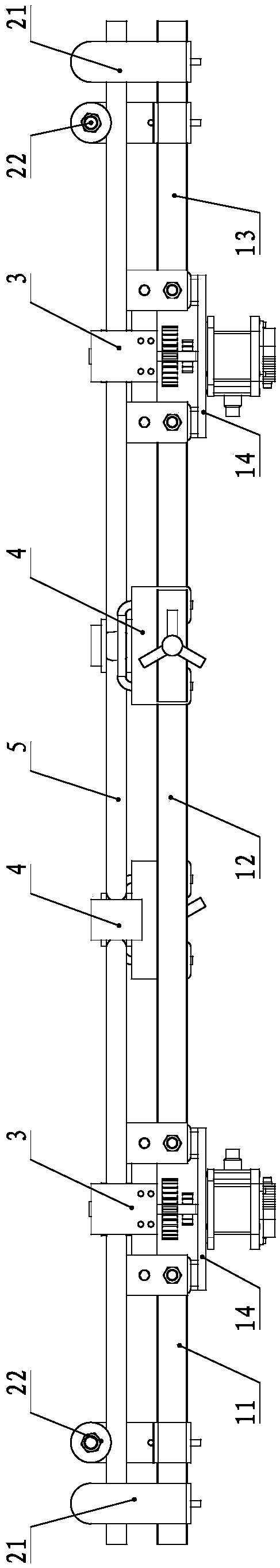

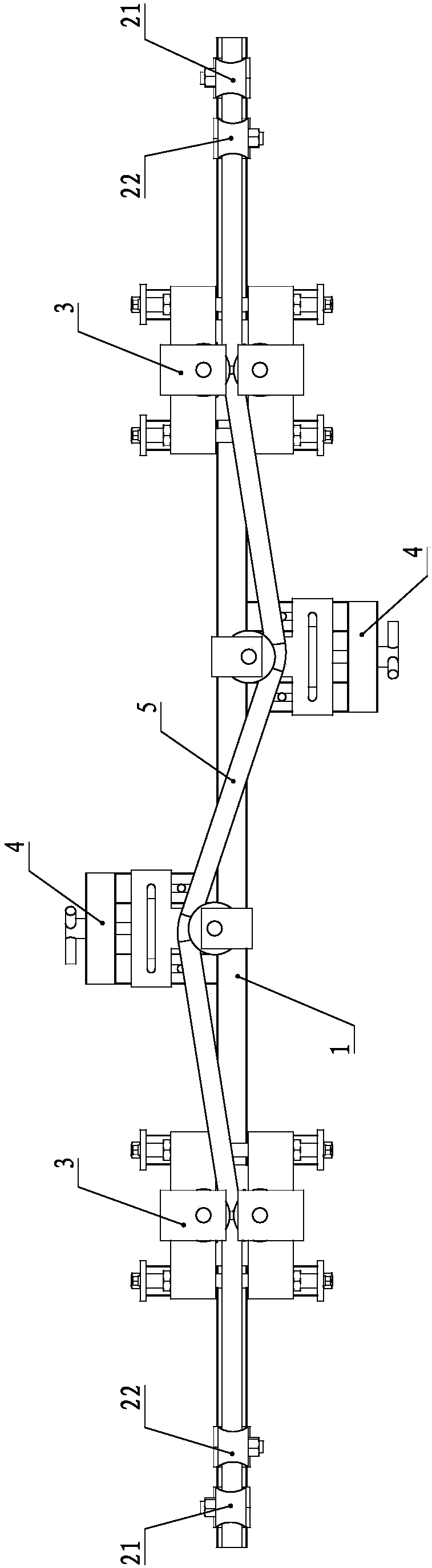

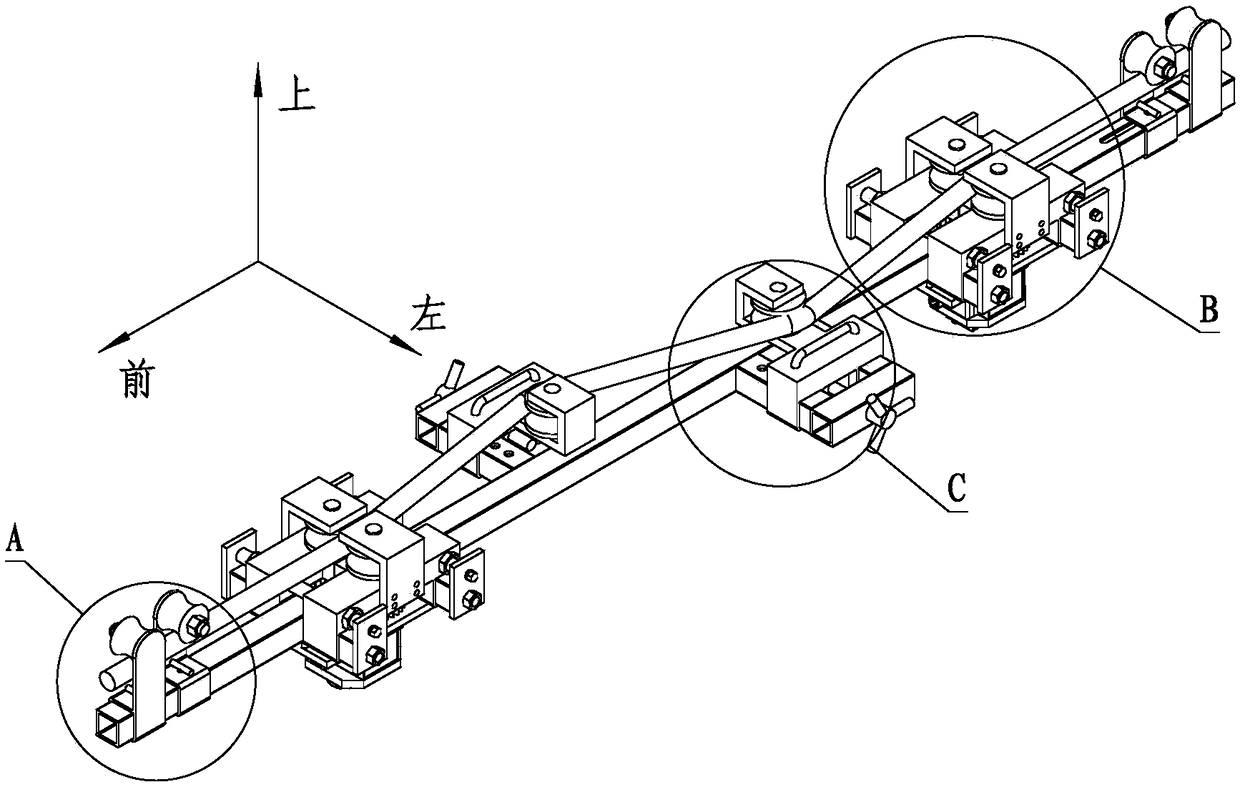

[0042] For the convenience of description, the coordinate system is defined as figure 1 , and the front and back directions are vertical, the left and right directions are horizontal, and the up and down directions are vertical.

[0043] Such as figure 1 , figure 2 with Figure 7 As shown, a five-way deicing device for a power transmission line includes a main frame body 1 , and the main frame body 1 includes a first longitudinal beam 11 , a second longitudinal beam 12 and a third longitudinal beam 13 sequentially from front to back. The first longitudinal beam 11 and the second longitudinal beam 12 are located on the lower side of the first longitudinal beam 11 and the second longitudinal beam 12, and the second longitudinal beam 12 and the third longitudinal beam 13 are located on the second longitudinal beam. The lower sides of the beam 12 and the third longitudinal beam 13 are respectively provided with motor mounting plates 14 . The rear end of the first longitudinal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com