Novel magnetic-resistance-type electromagnetic clutch

An electromagnetic clutch, reluctance technology, applied in electric brake/clutch, asynchronous induction clutch/brake, electrical components, etc., can solve the problems of reduced service life, large volume torque, degraded magnetic performance, etc., to achieve service life length, increase the amount of magnetoresistance change, and improve the effect of bonding torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

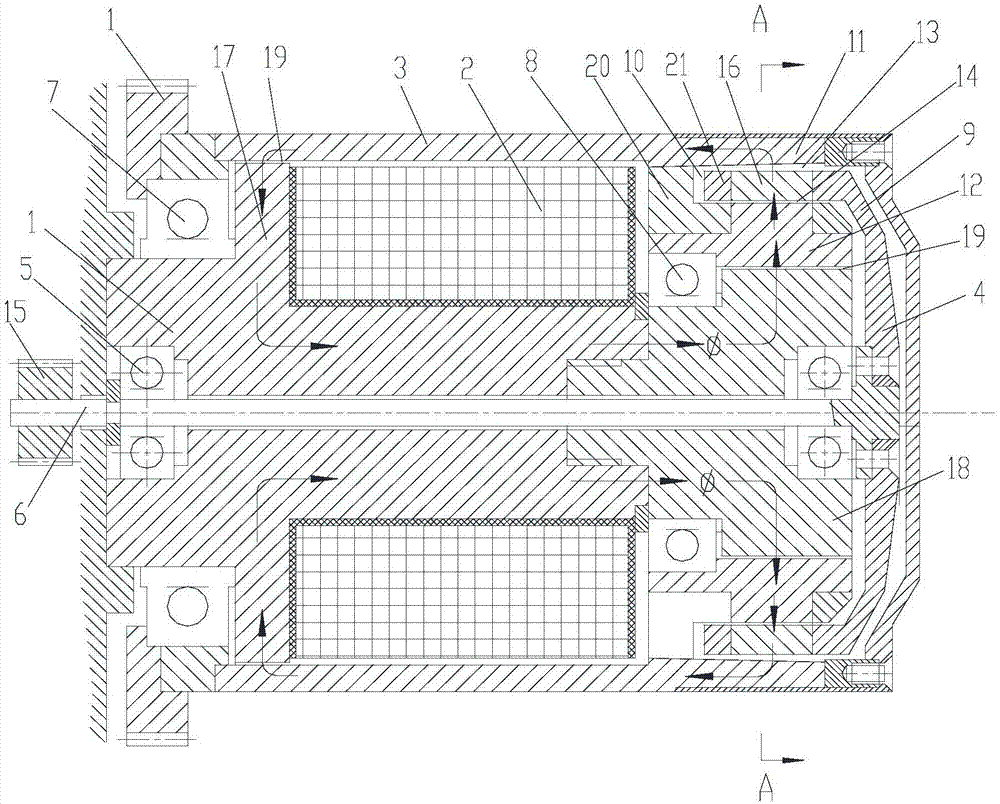

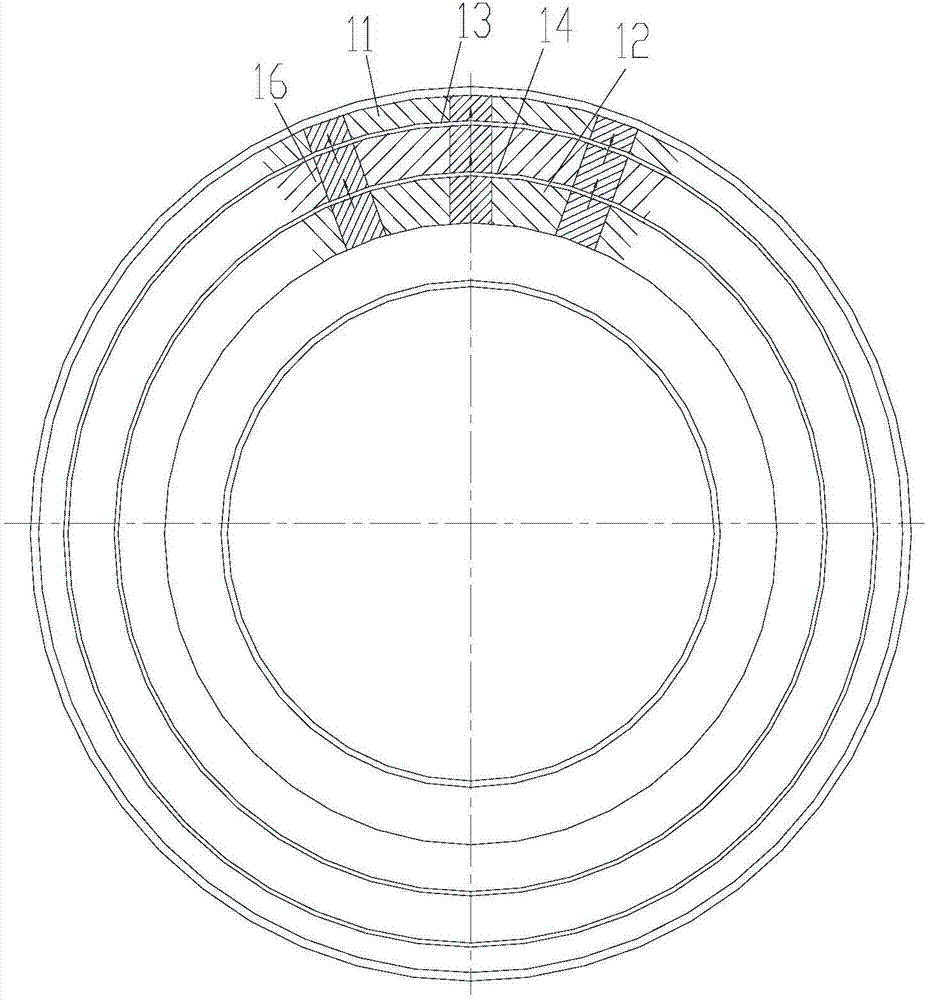

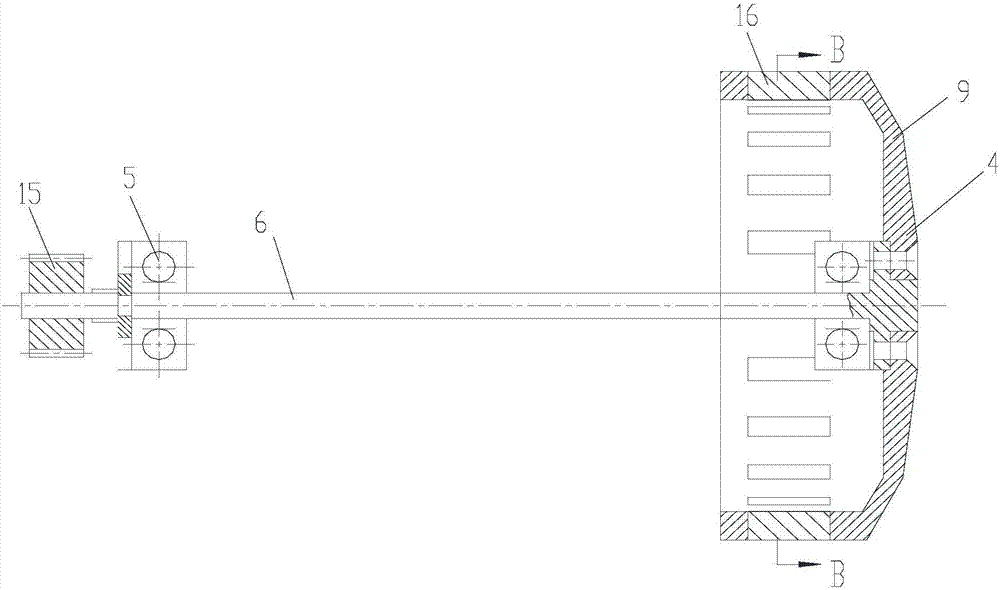

[0021] Attached below Figure 1-7 An embodiment of the present invention is described.

[0022] The new reluctance electromagnetic clutch has a stator 1, a winding 2 and a rotor. The rotor includes a driving rotor 3 and a driven rotor 4. The stator 1 is supported on the output shaft 6 of the driven rotor 4 through a bearing I5 and driven The rotor disk 9 on the rotor 4 is inserted into the annular space 10 on the active rotor disk 3, the active rotor 3 is supported on the outer circumference of the stator 1 through the bearing II7 and the bearing III8 and the winding 2 sleeved on the stator 1 is placed on the stator 1 and the driving rotor 3, specifically, the stator 1 is composed of a left stator 17 and a right stator 18, and the left stator 17 and the right stator 18 are connected and supported on the output shaft 6 through a bearing I5, The left side and the right side of the active rotor 3 are respectively supported on the outer circumference of the left stator 17 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com