Automatic shelling device of mytilus coruscus

A thick mussel, automatic technology, which is applied in the field of aquatic product processing equipment, can solve the problems of limited spraying range of nozzles, small number, affecting the separation of thick mussel shells and meat, etc., and achieves the effect of improving the separation rate of meat shells and expanding the spraying range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

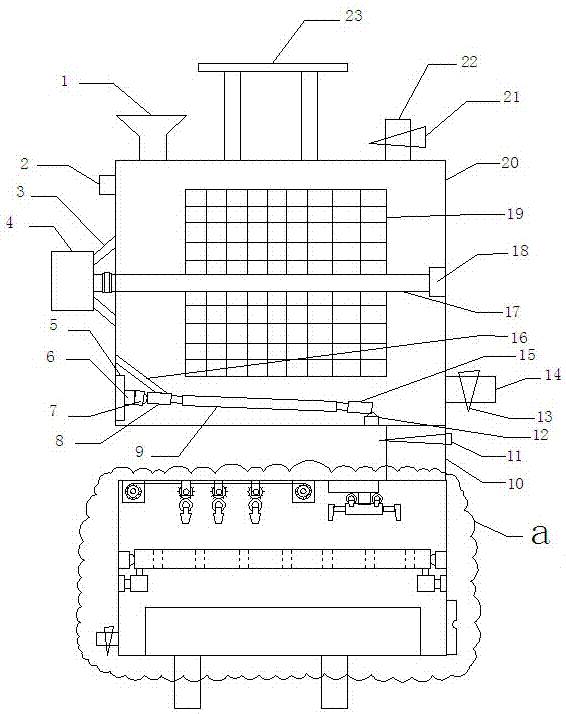

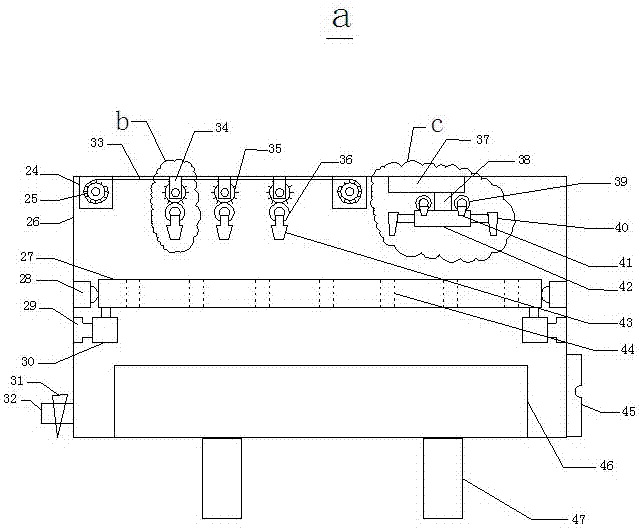

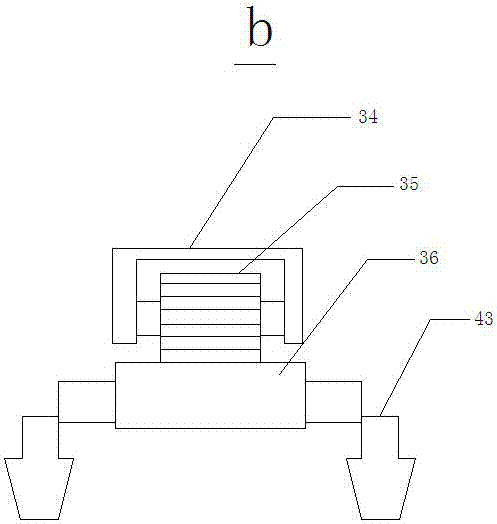

[0018]The present invention is an automatic shelling device for thick mussels, comprising a feed port 1, a controller 2, a base 3, a first motor 4, a first linear motor 5, a first moving block 6, and a first fisheye bearing 7 , the first telescopic plate 8, the support plate 9, the channel 10, the electric valve 11, the second fish-eye bearing 12, the first drain valve 13, the first water outlet pipe 14, the second telescopic plate 15, the baffle plate 16, the rotating shaft 17, Flange bearing 18, grid plate 19, first cabinet 20, water inlet valve 21, water inlet pipe 22, frame 23, second motor 24, second gear 25, second cabinet 26, vibrating plate 27, third fish Eye bearing 28, vibration isolation plate 29, vibration motor 30, second drain valve 31, second water outlet pipe 32, chain 33, wheel frame 34, first gear 35, first double-head cylinder 36, sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com