System and method for treating exhaust gas based on cold plasma fusion technique

A technology for cold plasma and waste gas treatment, which is applied in gas treatment, separation methods, chemical instruments and methods, etc. It can solve the problems that the waste gas treatment process is not easy to control, the packing needs to be replaced regularly, and the floor space is large, so as to reduce investment. The effect of low burden, low operating cost and small land occupation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to better illustrate the purpose, technical solutions and advantages of the present invention, the present invention will be further described below in conjunction with specific examples.

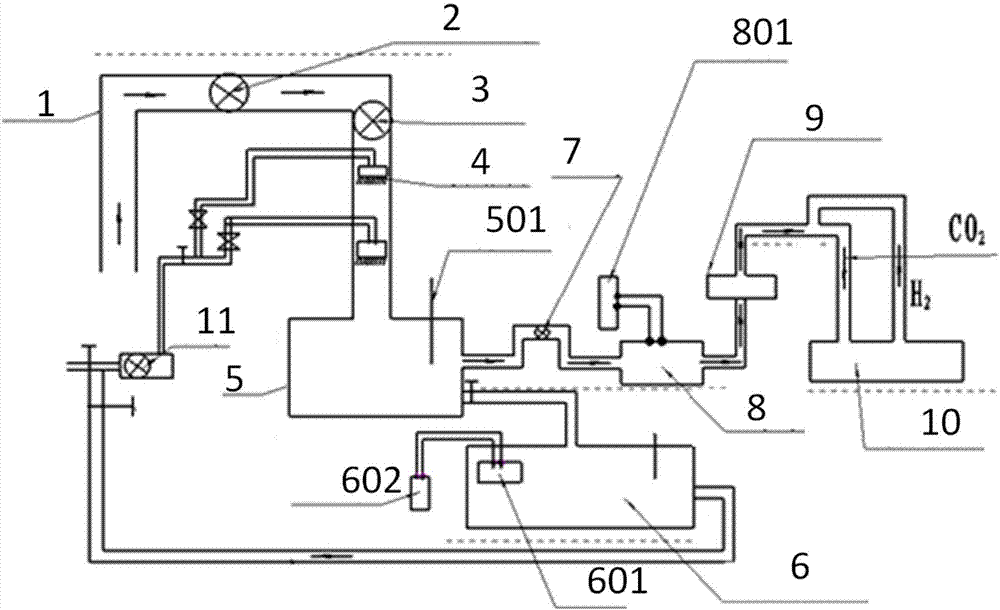

[0019] An embodiment of the cold plasma fusion technology exhaust gas treatment system of the cold plasma fusion reactor technology described in the present invention, the structural diagram is as attached figure 1 As shown, it includes exhaust gas input pipe 1, electrostatic smoke removal device 2, suction fan I 3, spray device 4, water tank 5, electrode generator 6, suction fan II 7, cold plasma generator 8, and cold plasma fusion reaction chamber 9. Formaldehyde synthesis workshop 10 and water pump 11.

[0020] Described waste gas input pipe 1 is provided with electrostatic smoke removal device 2, suction fan 13 and spray device 4, and the water outlet of described spray device 4 links to each other with water tank 5, and described water tank 5 is provided with water outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com