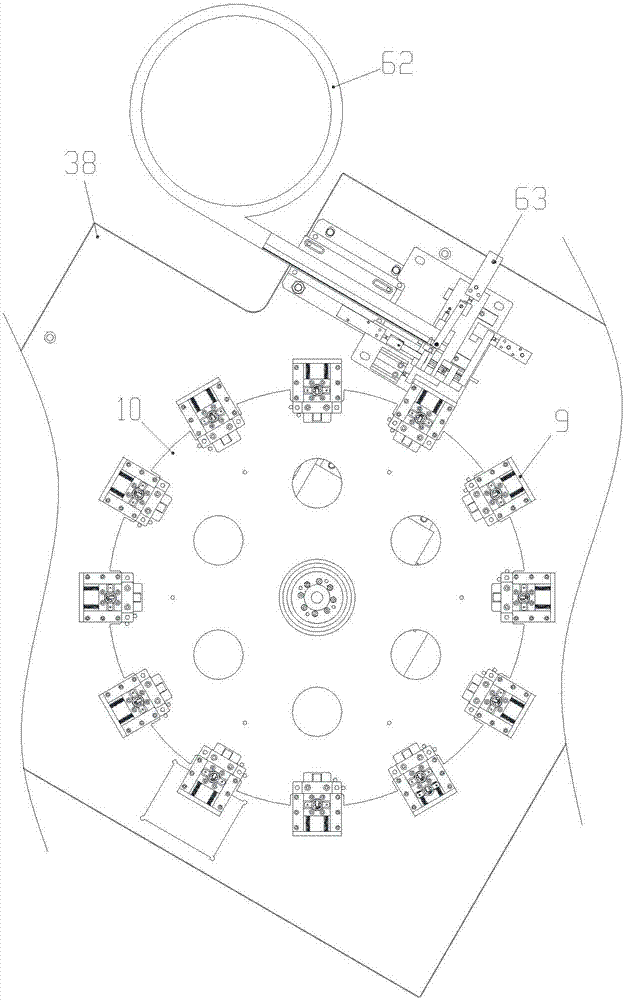

High-speed assembly line device for electronic elements

A technology for assembly lines and electronic components, applied to assembly machines, metal processing equipment, manufacturing tools, etc., can solve problems such as complex structures, difficult feeding, and easy deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

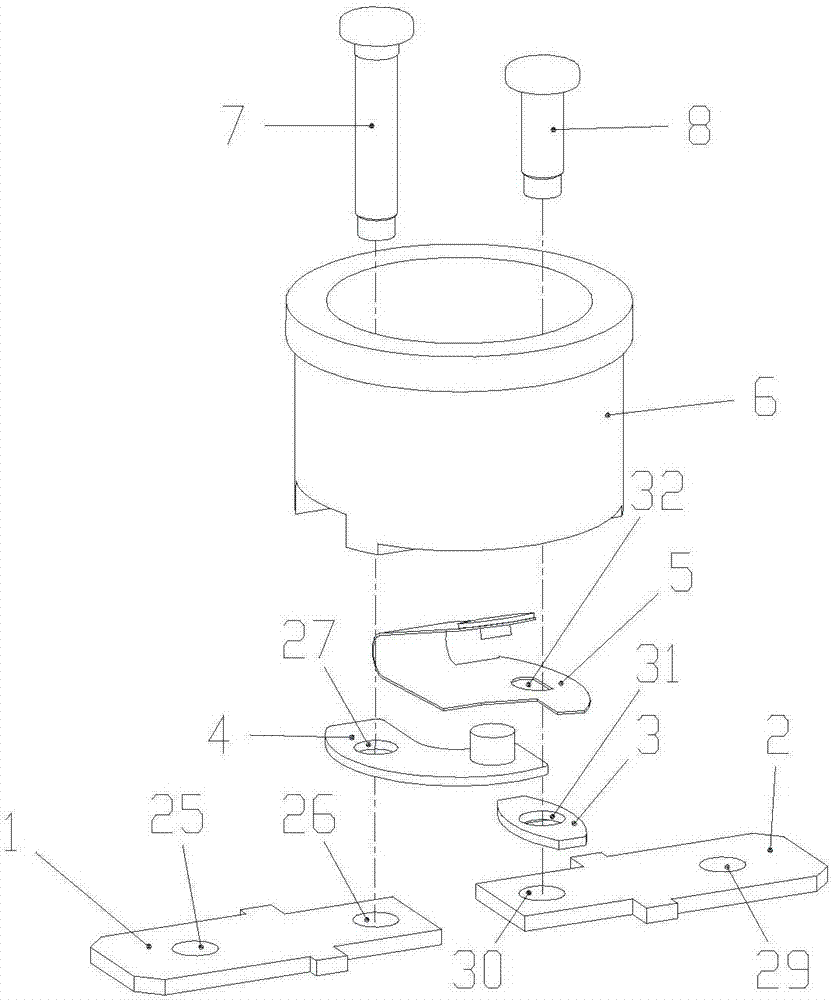

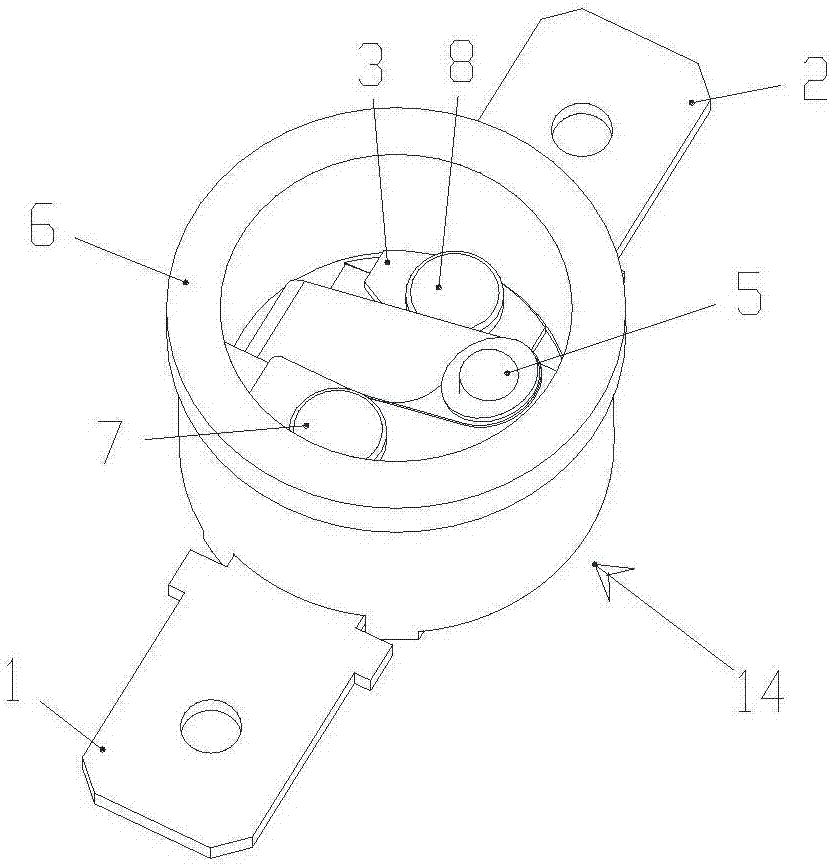

[0050] The present invention will be further described in detail below in conjunction with the accompanying drawings, but does not constitute any limitation to the present invention. Similar component numbers in the accompanying drawings represent similar components. As mentioned above, the present invention provides a high-speed assembly line equipment for electronic components, which is applied in the production and assembly process of the contact mechanism of electrical products. The present invention is used to output the moving electrodes to a specific position in an orderly manner. , cooperate with the automation mechanism in the back channel to realize the automatic assembly of the moving electrode. The high-speed assembly line equipment for electronic components of the present invention realizes the orderly output of thin-walled elastic parts, effectively avoids stacking and material jamming, and provides a technical basis for realizing automatic operation of electrical...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap