Method by using andradite one-step alkaline heat process to treat Bayer process red mud to produce metallurgical aluminum oxide

A technology for Bayer process red mud and calcium iron garnet, which is applied in the field of one-step alkaline heat treatment of calcium iron garnet to produce metallurgical grade alumina, can solve the problem of unsatisfactory effect, unfavorable red mud application, waste of raw materials, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In this embodiment, diaspore Bayer process red mud is used, and the main chemical composition (mass percentage, wt%) is: alumina (Al 2 o 3 ) 21.62%, silicon dioxide (SiO 2 )16.11%, sodium oxide (Na 2 O) 7.08%, calcium oxide (CaO) 16.50%, total iron (TFe) 14.80%, and its aluminum-silicon ratio is 1.34;

[0038] Sodium ferrite is sintered from iron-containing raw materials and industrial caustic soda;

[0039] The caustic concentration in the circulating mother liquor is 240g / L, and the molecular ratio is 25;

[0040] F / A=0.6:1;

[0041] C / S=2.5:1.

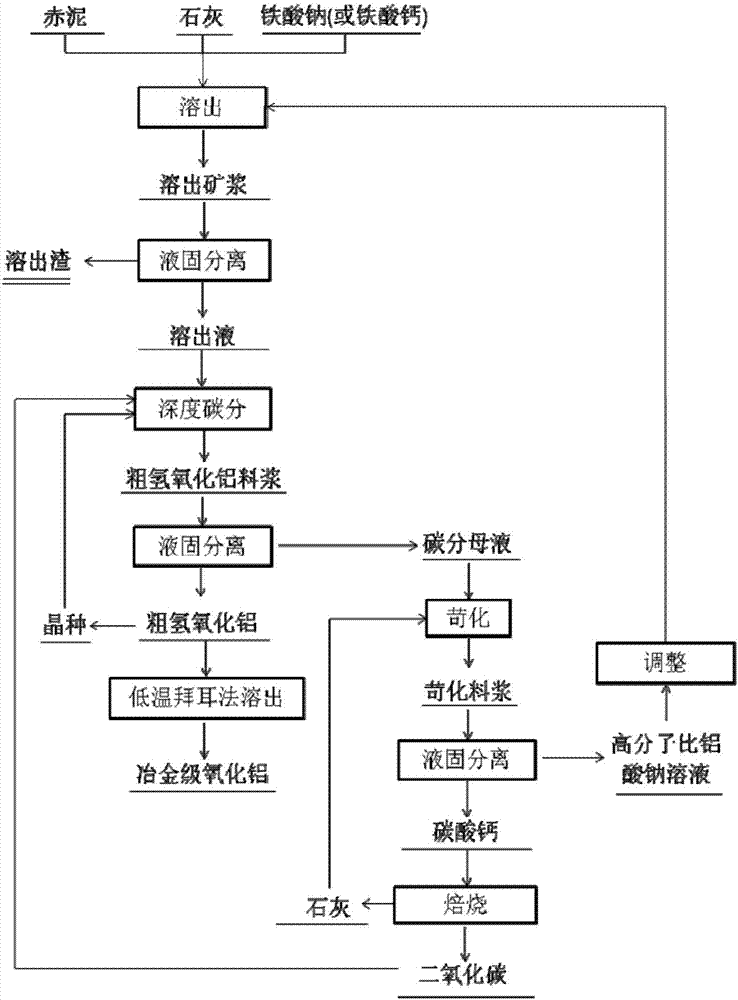

[0042] according to this figure 1The method for the production of sodium aluminate by the one-step alkali-thermal process of the present invention with andradite red mud of Bayer process as shown:

[0043] S1: After mixing red mud, sodium ferrite and active lime, mix it with circulating mother liquor according to the ratio of L / S=4:1 to prepare raw material slurry;

[0044] S2: The raw material pulp is subjected to al...

Embodiment 2

[0058] This embodiment adopts Bayer process red mud, and its main chemical composition (mass percentage, wt%) is: alumina (Al 2 o 3 ) 23.35%, silicon dioxide (SiO 2 ) 23.23%, sodium oxide (Na 2 O) 15.61%, calcium oxide (CaO) 0.51%, total iron (TFe) 16.16%, titanium dioxide (TiO 2 )5.37%, and its aluminum-silicon ratio is 1.01;

[0059] Calcium ferrite is sintered from iron-containing raw materials and industrial lime;

[0060] The caustic concentration in the circulating mother liquor is 240g / L, and the molecular ratio is 20;

[0061] F / A=1:1;

[0062] C / S=3.0:1.

[0063] according to this figure 1 The method for the production of sodium aluminate by the one-step alkali-thermal process of the present invention with andradite red mud of Bayer process as shown:

[0064] S1: After mixing red mud, calcium ferrite and lime, mix them with circulating mother liquor according to the ratio of L / S=5:1 to prepare raw material slurry (note: TiO2 in raw materials should be consider...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com