Preparation method of high-strength and high-plasticity Ni-Mn-Ga-Nb memory alloy

A memory alloy and high plasticity technology, which is applied in the field of high strength and high plasticity Ni-Mn-Ga-Nb memory alloy preparation, can solve the problems of small restoring force, low strength, and high brittleness of NiMnGa alloy, and achieve high toughness and fracture The effect of high strength and increased fracture strain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The high-strength, high-plasticity Ni of this embodiment 53 mn 25 Ga 21 Nb 1 The preparation method of the memory alloy is prepared as follows: according to the atomic percentage, 53 parts of Ni, 25 parts of Mn, 21 parts of Ga and 1 part of Nb are put into a vacuum intermediate frequency induction melting furnace, and the raw materials are placed in the following order: first place rare elements Nb, Ni is placed next, Ga is placed last, Mn is placed in the smelting furnace for standby, and the side furnace door is closed. Before smelting, vacuumize to 6.67×10 with mechanical pump and Roots pump -3 Pa, then filled with high-purity argon to 0.5Pa. Start smelting and control the smelting power between 350-500Kw. After the molten metal liquid is fully mixed, add Mn at last, pour the alloy liquid into the rod-shaped mold for 3-5 minutes, and obtain a rod-shaped sample of Φ12mm×60mm, and take it out after cooling. The test materials were wire-cut and mechanically polish...

Embodiment 2

[0027] The high-strength, high-plasticity Ni of this embodiment 53 mn 25 Ga 21 Nb 1The difference between the memory alloy and Example 1 is that the aging temperature and aging time are changed, and the aging time is fixed at 3 hours. The specific steps are as follows: heat the samples to 500°C, 600°C, 700°C and 800°C for 3 hours and then quench them into water to obtain high-strength, high-plasticity Ni 53 mn 25 Ga 21 Nb 1 Shape Memory Alloys.

Embodiment 3

[0029] This embodiment high strength, high plasticity Ni 53 mn 25 Ga 21 Nb 1 The difference between the memory alloy and Example 1 is that the aging time is changed to 0.5h, 1h, 3h and 5h under the condition that the aging temperature is kept constant at 700°C.

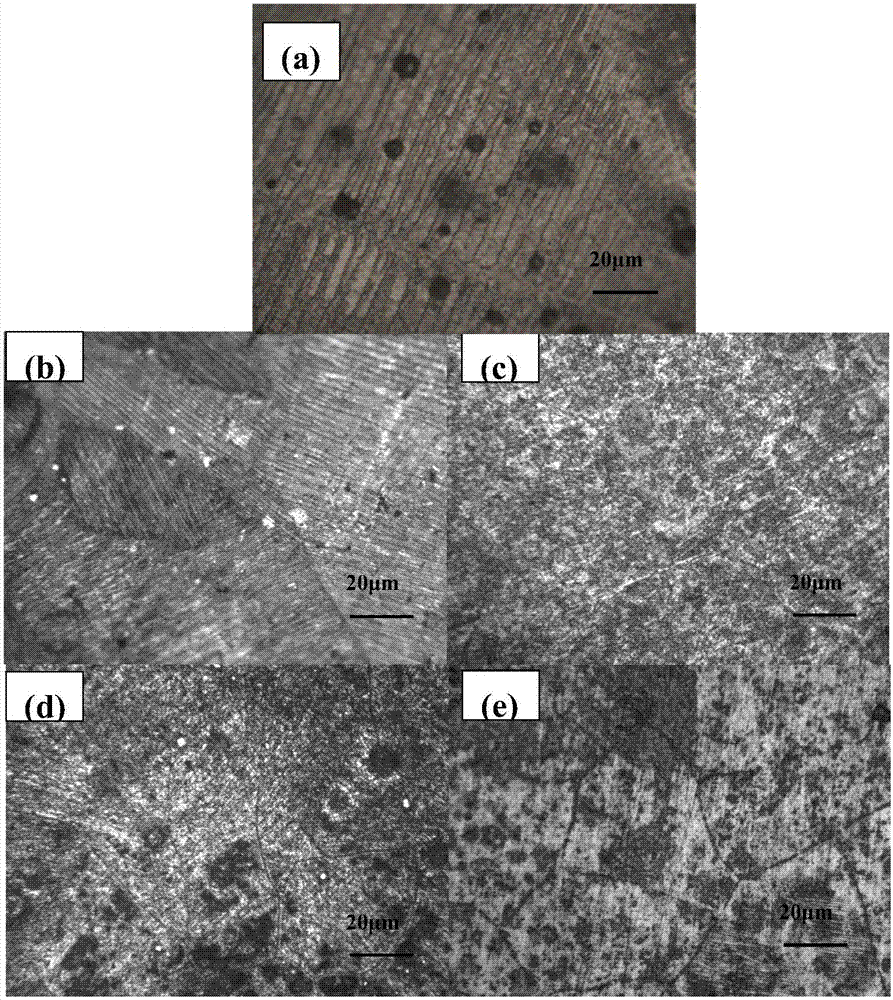

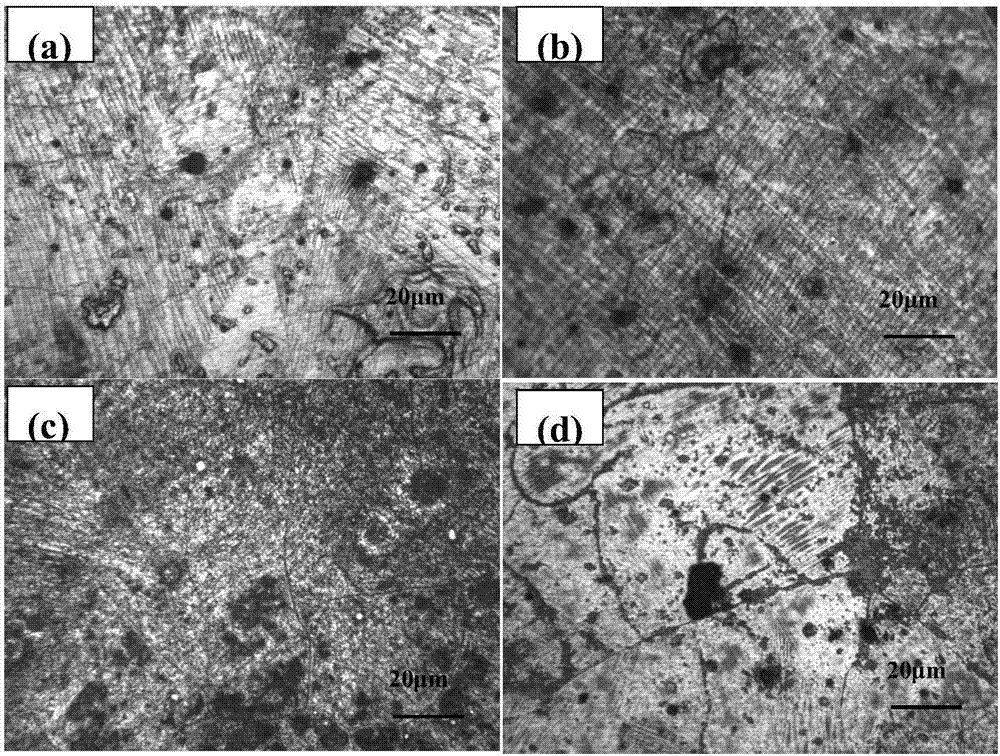

[0030] The novel high strength, high plasticity Ni prepared by present embodiment 2 and embodiment 3 53 mn 25 Ga 21 Nb 1 Alloy structure analysis, through figure 1 It can be seen that the precipitated phases in all alloys increase first and then decrease with the increase of aging temperature, and the number of precipitated phases is the largest after aging treatment at 700℃ / 3h. From figure 2 It can be seen that the number of precipitates in the alloy increases first and then decreases with the increase of aging time.

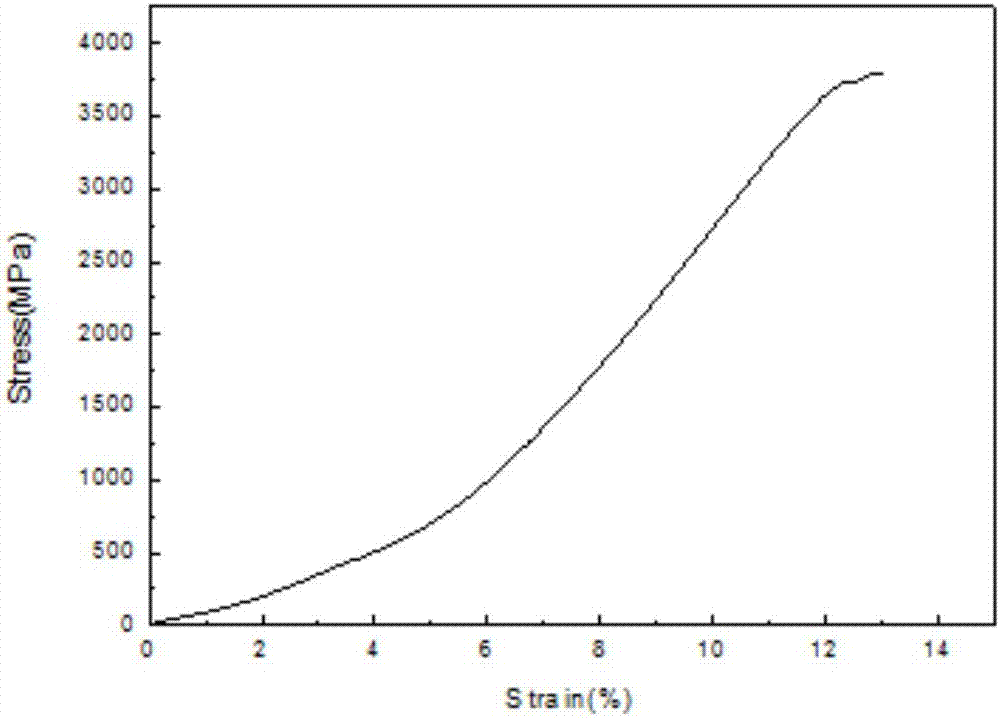

[0031] The high-strength, high-plasticity alloy prepared in present embodiment 2 is carried out the test of breaking strength and breaking strain, and test result is as follows image 3 As s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| fracture strain | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com