Multifunctional sensor based on double-gate thin film transistor and preparation method thereof

A thin-film transistor and multi-functional technology, applied in the field of sensors, can solve the problems of high production cost, crosstalk between adjacent components, affecting detection accuracy, etc., and achieve the effect of saving preparation time, improving efficiency and providing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

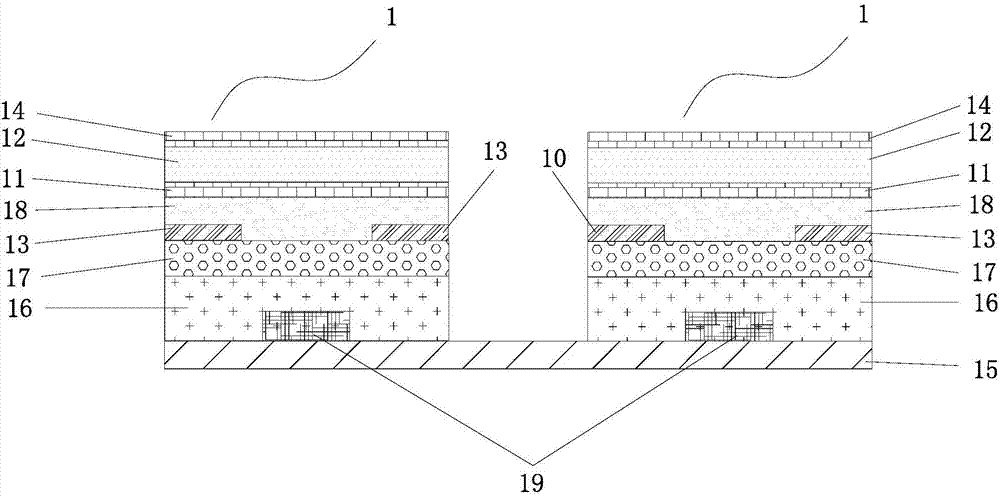

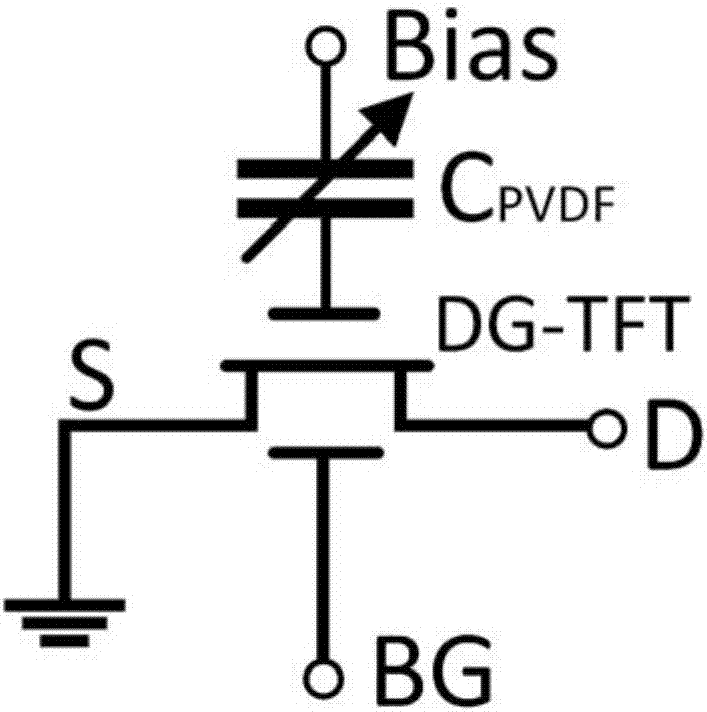

[0045] The physical field in this embodiment includes a thermal field and a force field, that is, after being coupled with the double-gate thin film transistor 1, a sensor with temperature sensing and pressure sensing is formed. Specifically, it includes a sensor integrated on the same flexible substrate 15 and At least two double-gate thin film transistors 1 that are independent of each other, wherein at least one of the double-gate thin film transistors 1 is provided with a polarized piezoelectric material 12 or a non-polarized piezoelectric material 12 on the surface of the top gate 11; The surface of the piezoelectric material 12 is also provided with a metal material 14 . That is to say, at least one of them is used as a temperature sensing part, and one is used as a pressure sensing part.

[0046] Therefore, in the specific use process, when the external temperature changes, the non-polarized piezoelectric material changes, that is, the capacitance changes, and then the ...

Embodiment 2

[0069] The only difference between this embodiment and Embodiment 1 is that the number of double-gate thin film transistors 1 provided in the present invention is three, specifically as Figure 4 As shown, the multi-functional sensor based on double-gate thin film transistors includes three double-gate thin film transistors 1, wherein the surface of the top gate 11 of one is provided with a polarized piezoelectric material 12, and the top gates of the other two A non-polarized piezoelectric material 12 is provided on the surface of the pole 11 , and then a metal material 14 is provided on the surface of the piezoelectric material 12 . That is to say: the dual-gate TFT-based multifunctional sensor of the present invention is provided with two temperature sensing parts and a single pressure sensing part. Its specific working principle and preparation method are consistent with those in Example 1, and will not be repeated here.

Embodiment 3

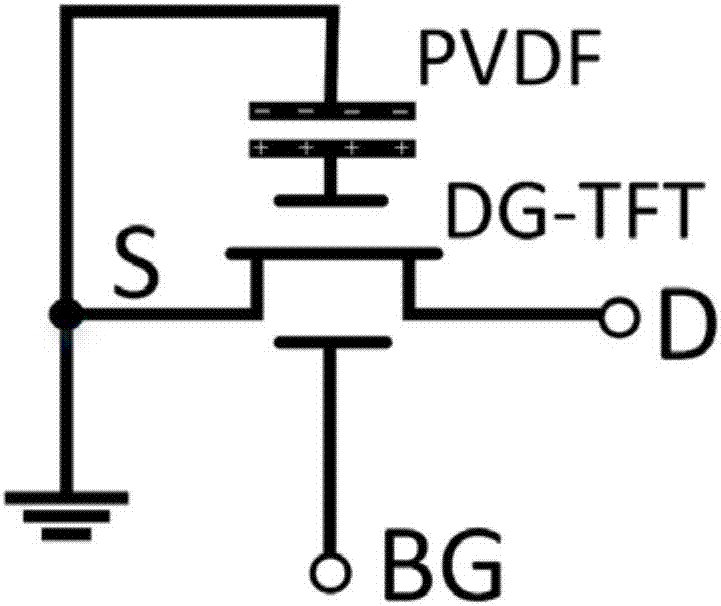

[0071] The difference between this embodiment and Embodiment 1 is that the physical field is a magnetic field, which is coupled with the top gate 11 of the double-gate thin film transistor 1 to form a magnetic sensor, which is used in combination with a memristor, such as Figure 5 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com