Vehicle transverse stabilizer bar durability test bench

A technology of lateral stabilizer bar and durability test, which is used in vehicle testing, machine/structural component testing, and measuring devices, etc., can solve the problems of poor test bench versatility, low test frequency, and small number of tests, and saves the test. Time cost, strong versatility, and the effect of reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

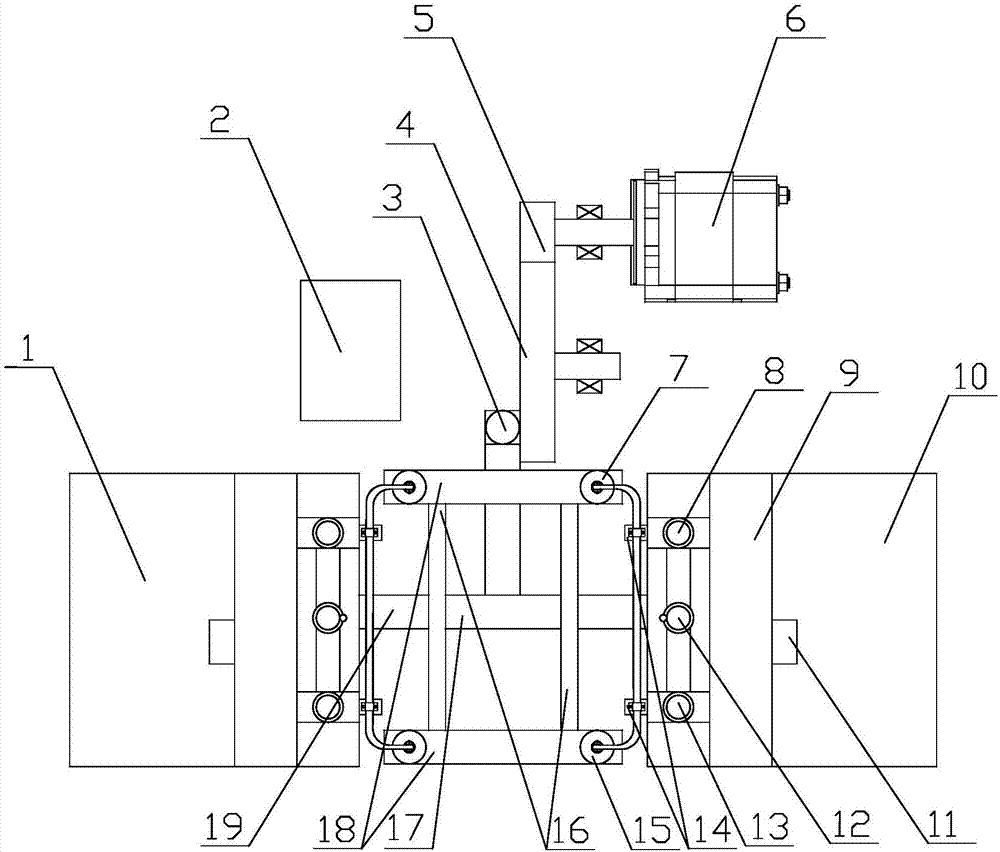

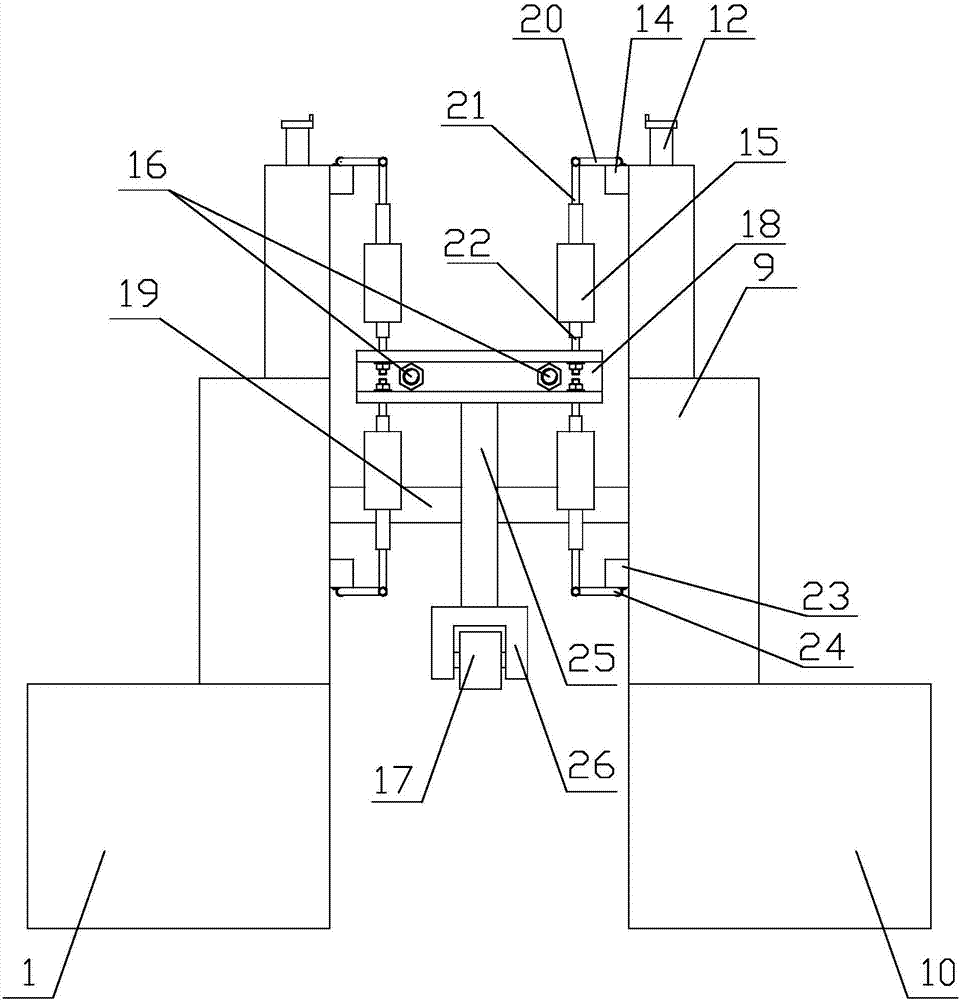

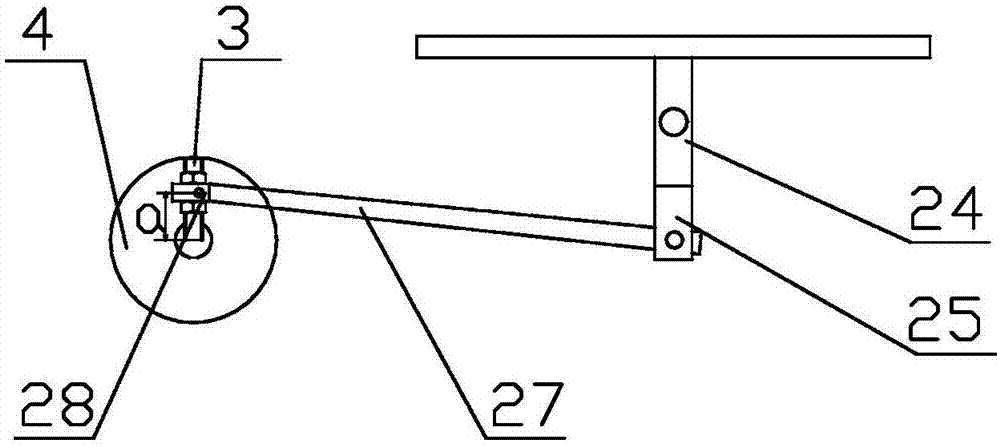

[0024] Such as Figure 1 to Figure 2 A kind of automobile anti-stabilizer durability test bench shown, comprises: drive system, and this drive system comprises the control cabinet 2 of control motor 6 and drive wheel 5, and motor 6 can have stepper motor under the instruction of main control computer function, which can be used to collect the force value of the set amplitude and the maximum amplitude point, and set the dynamic frequency of the test at the same time; the transmission system, the transmission system includes the driven wheel 4, the swing arm 25 and the transmission shaft 27, the driven wheel 4 One end is connected to the driving wheel 5, the other end is connected to the amplitude adjustment rod 3, the swing arm 25 is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com