Variable circulation low-resistance control system for automobile engine

A technology of automobile engine and control system, which is applied in the direction of engine control, engine components, combustion engine, etc., can solve the problems of increasing automobile operating cost, increasing failure rate, and large wear of the separation bearing of the clutch, so as to avoid the car from sliding Speed drop too fast, high fuel efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

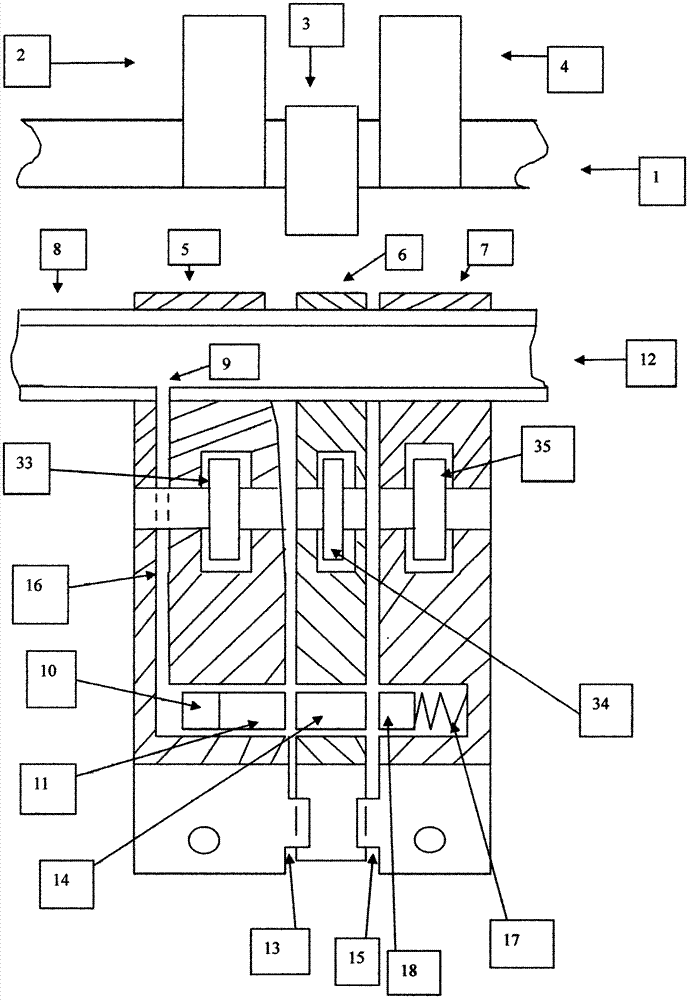

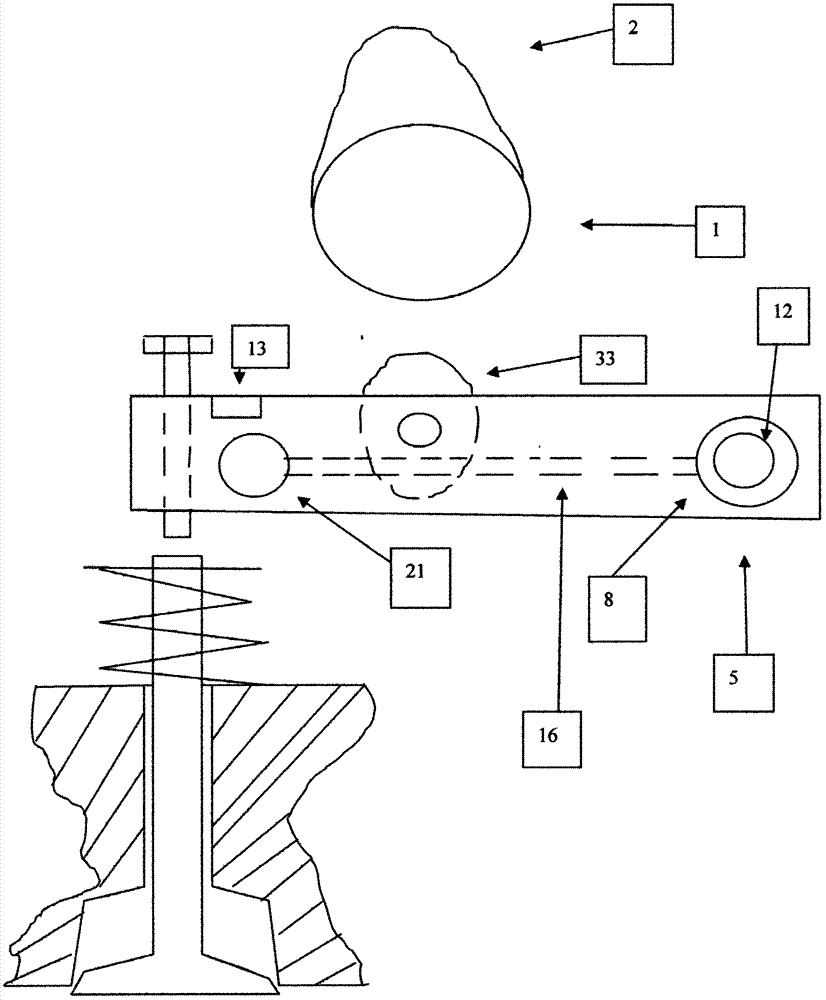

[0023] The automobile engine variable cycle low resistance control system is composed of cylinder head (23), camshaft (1), first exhaust rocker arm, second exhaust rocker arm (7), variable cycle rocker arm (6) rocker shaft (8), timing piston (10), first synchronous piston (11), second synchronous piston resistance (14), blocking piston (18), return spring (17), first roller bearing (33), second Roller bearing (35), third roller bearing (34), engine oil pipe (32), solenoid valve (27), electric motor oil pump (36), pressure stabilizing valve (37) and variable cycle control circuit (31) .

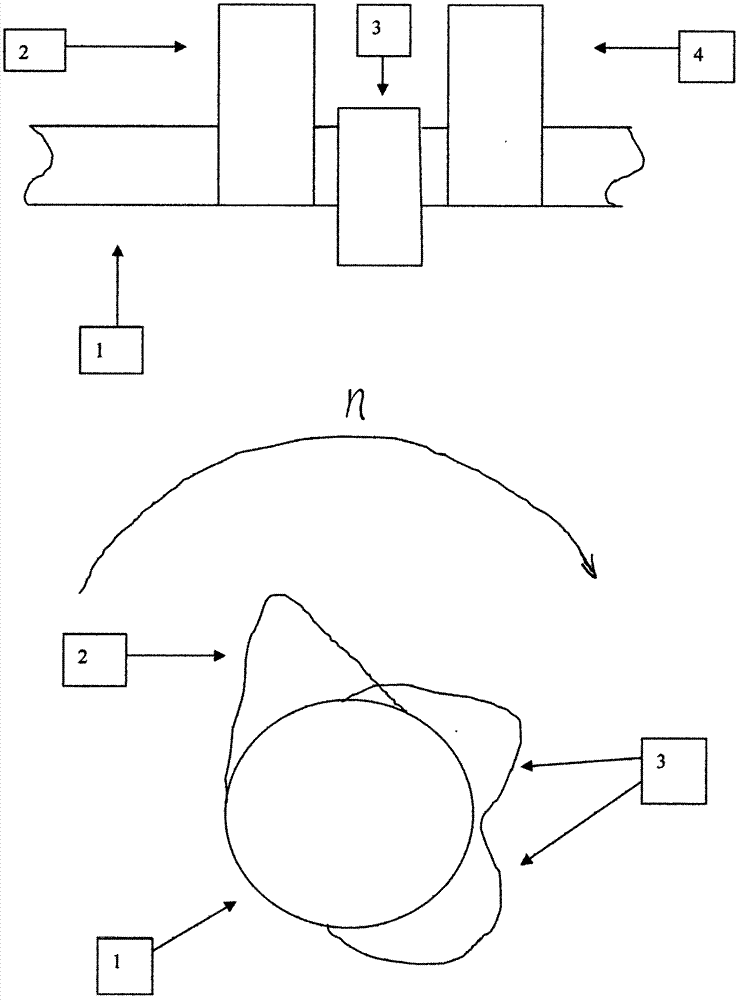

[0024] exist figure 1 , the camshaft (1) has the first exhaust cam (2), the second exhaust cam (4) and the variable cycle cam (3), and the rotation direction n shows the variable cycle cam (3) and the first intake cam (2) and the corresponding position of the second intake cam (4).

[0025] exist figure 2 Among them, the function of the first exhaust cam (2) and the second exhaust cam (4)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com