Tea cylinder fixation machine

A technology of a drum fixing machine and tea leaves, which is applied in the direction of tea treatment before extraction, can solve the problems of easily producing coke leaves or yellow leaves, affecting the taste and appearance of tea leaves, and destroying the internal structure of tea leaves, so as to reduce the production of yellow leaves and speed up the production of tea leaves. The effect of heat dissipation and improving the quality of greening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

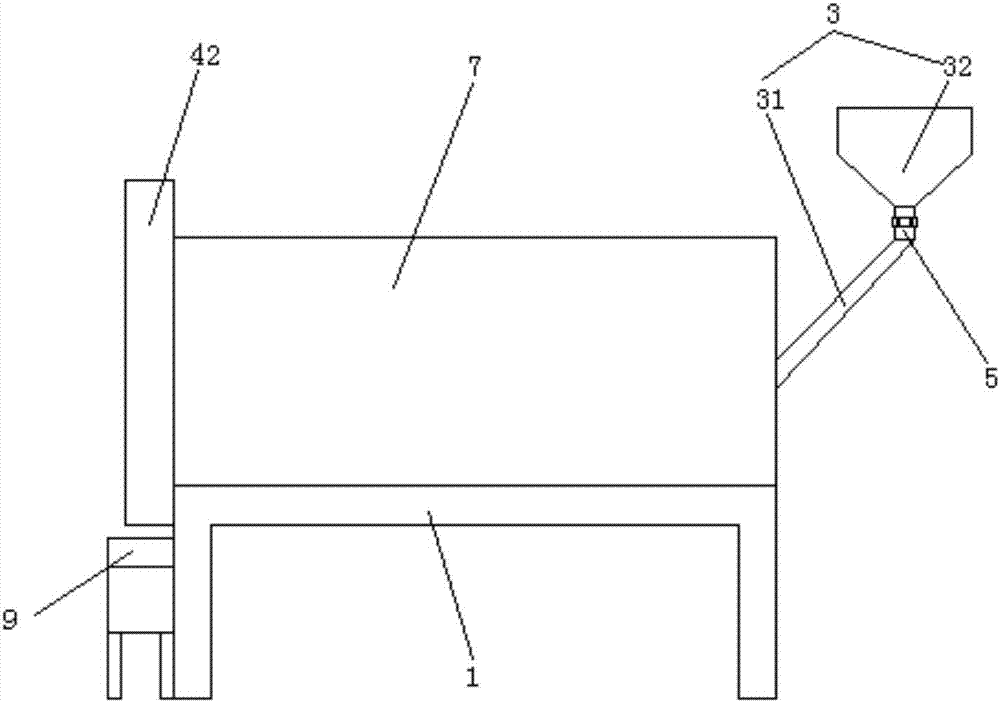

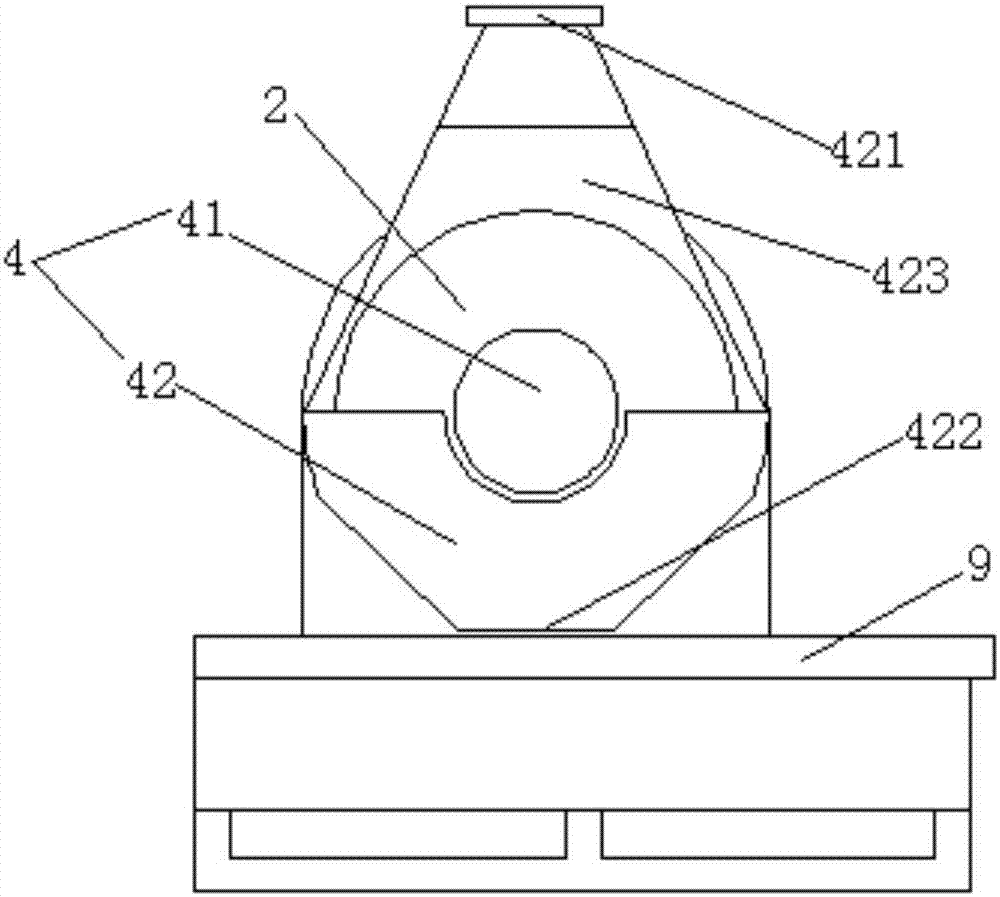

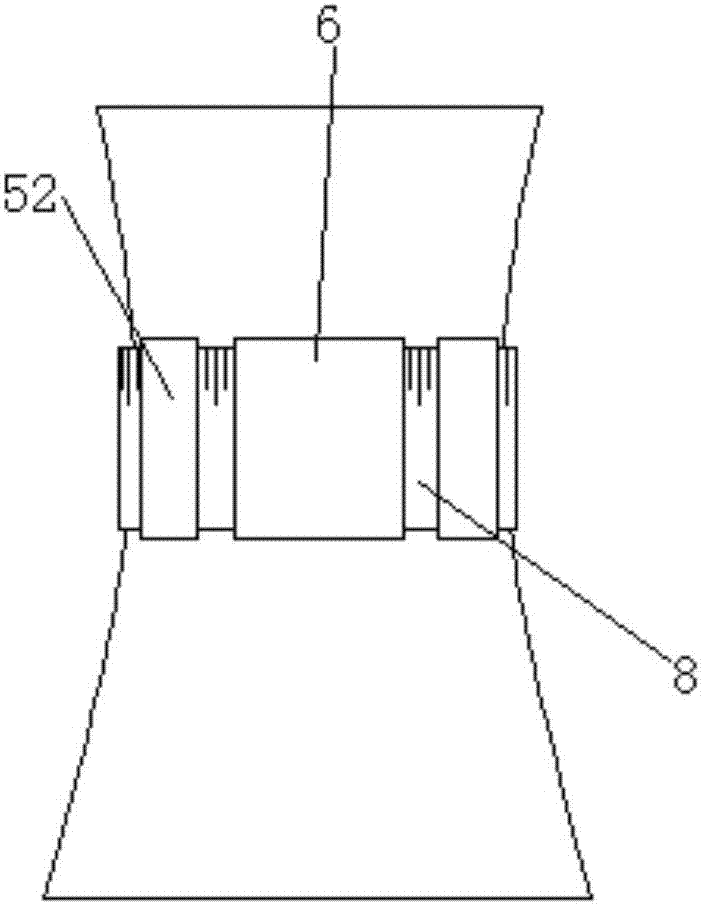

[0022] As shown in the accompanying drawings, a tea drum degreening machine includes a support 1, a drum 2, a heating device, a feed structure 3 and a discharge structure 4; the feed structure 3 includes a leaf transport groove 31 connected to the entrance of the drum 2 And the leaf storage bucket 32 fixed on the top of the leaf transport tank 31, the outlet of the leaf storage bucket 32 is fixed with an annular inflatable cloth 5, and a tea channel 51 is formed in the middle of the annular inflatable cloth 5, and the outer wall of the annular inflatable cloth 5 A limit structure 6 is arranged around, and a drum shell 7 for installing the drum 2 is fixed on the support 1, a cavity for accommodating a heating device is reserved between the drum shell 7 and the drum 2, and the inner wall of the drum 2 is installed with Spiral guide vanes, the discharge structure 4 includes a discharge port 41 and a guide vane box 42 fixed around the discharge port 41, the guide vane box 42 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com