Dedusting purifying device for energy-saving environment-friendly melting casting furnace

An energy-saving, environmental-friendly, purification equipment technology, applied in climate change adaptation, human health protection, chemical instruments and methods, etc., can solve problems such as poor filtering effect, poor pressure of dust collectors, and inability to achieve deep filtration, etc., to achieve good results, Avoid the effect of polluting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

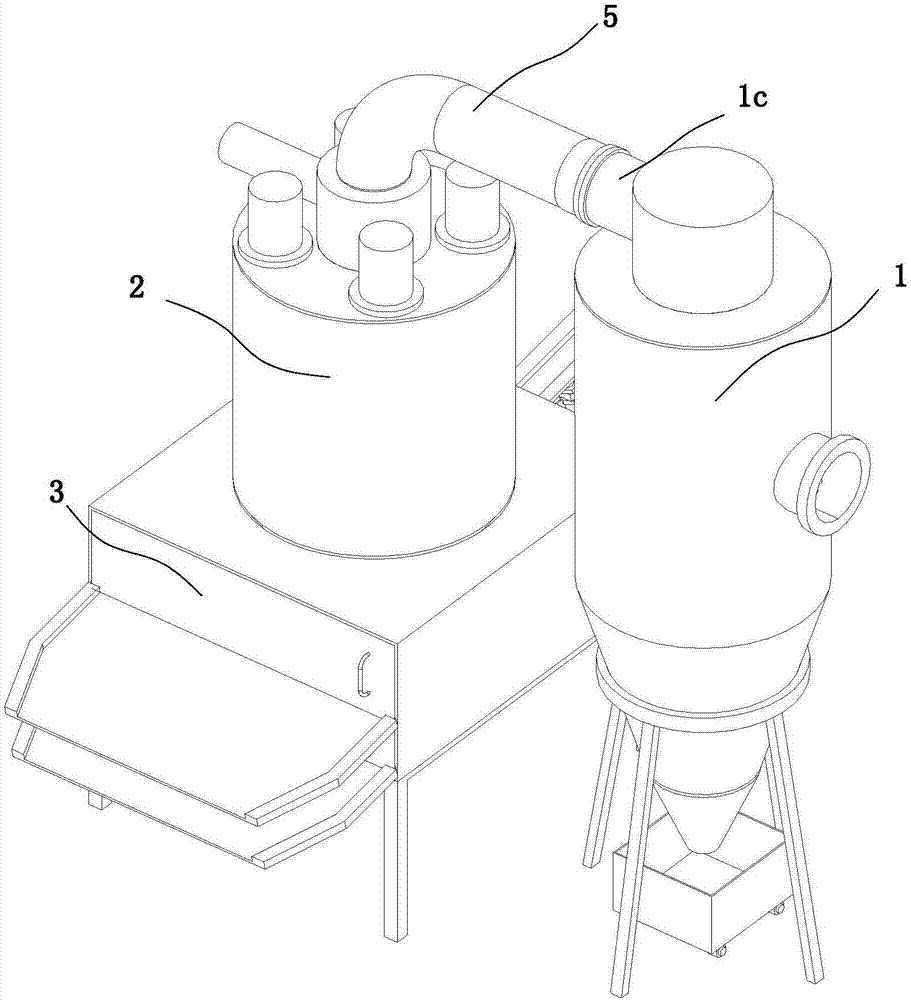

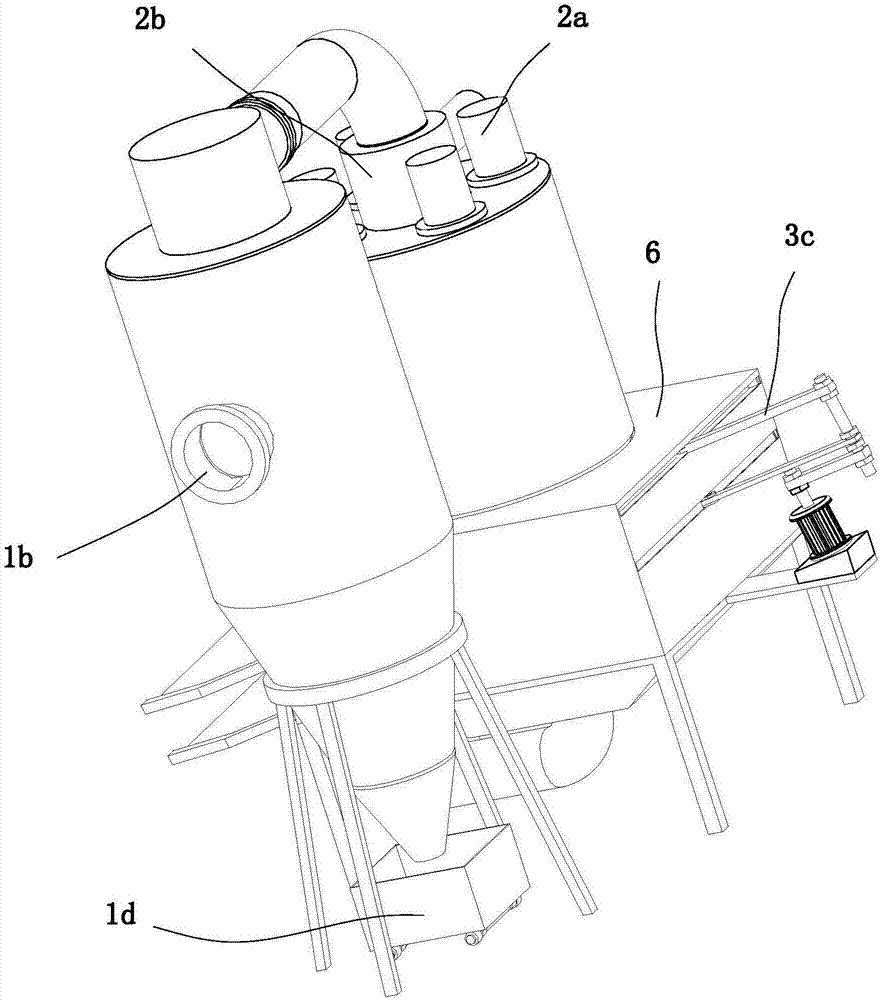

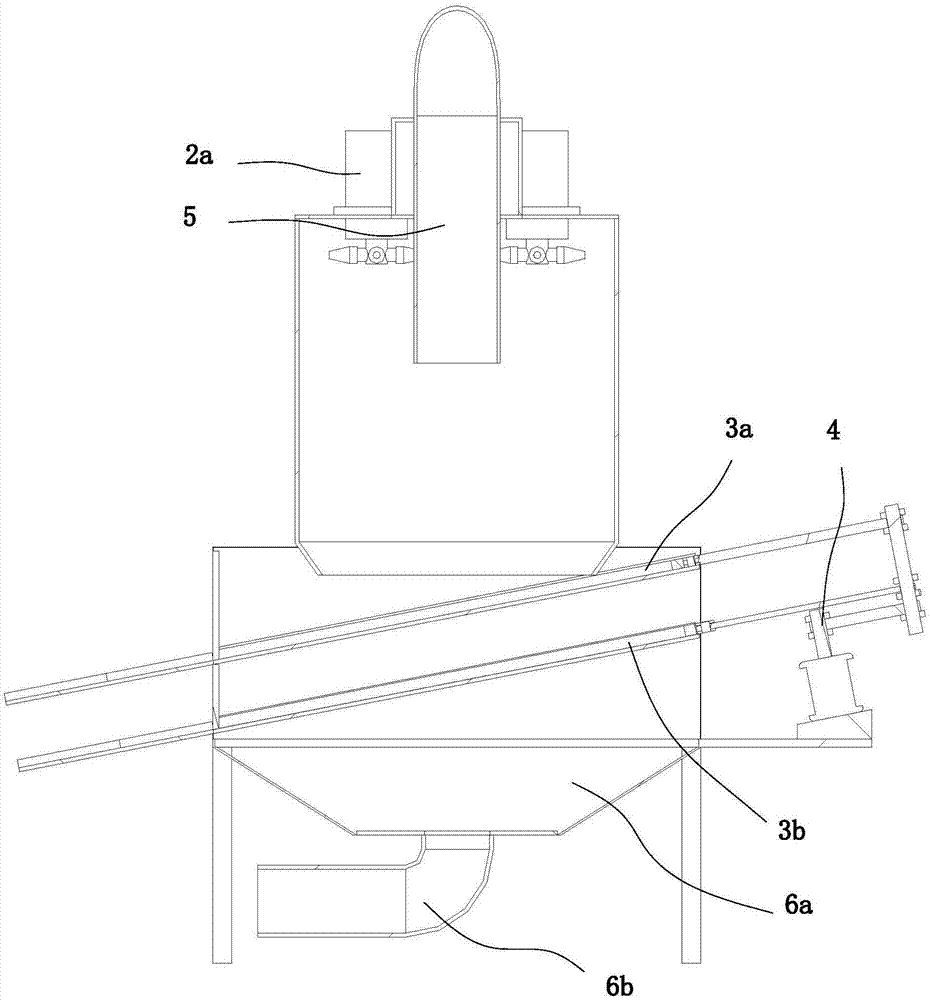

[0028] refer to Figure 1 to Figure 9 The shown dust removal and purification equipment for an energy-saving and environment-friendly melting and casting furnace includes a dust removal tank 1, a purification tank 2 and a filter device 3. 2, the upper part of the dust removal tank 1 is provided with a spiral panel 1a that spirals up along its axis, and the top of the spiral panel 1a is provided with several spirally ascending support bars 1e, and the spiral panel 1a passes through all the support bars 1e and the dust removal tank. The inside of 1 is fixedly connected, the top of the purification tank 2 is provided with several nozzles 2a, and the water outlet end of each nozzle 2a extends into the purification tank 2, and the filter device 3 includes a primary filter 3a, a secondary filter 3b and To clean the clean...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com