Waste cotton-polyester blended fabric component separation method

A polyester-cotton blending and separation method technology, applied in separation methods, filtration separation, chemical instruments and methods, etc., can solve the problems of winding, stirring and discharging, difficulties, etc., and achieve high-efficiency polyester-cotton separation, reduce damage, and enhance mass transfer. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

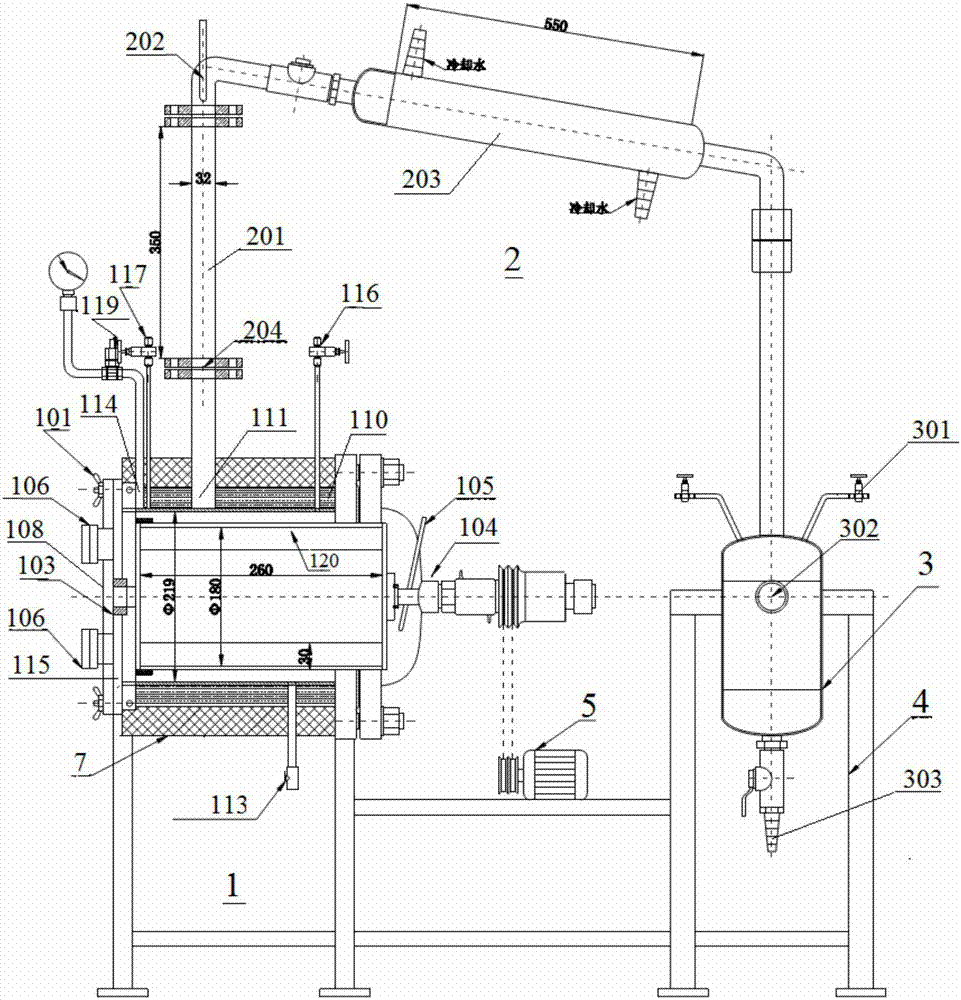

[0026] Example 1 Centrifugal waste polyester-cotton blended fabric component separation device

[0027] Such as figure 1 As shown, in a preferred embodiment of the present invention, the device includes a horizontal rotatable alcoholysis tank 1 , a reflux condensation device 2 , a collecting tank 3 , a vacuum device and a motor 5 .

[0028] The horizontal rotatable alcoholysis tank 1 is composed of an outer cylinder 110 and an inner cylinder 120 .

[0029] The outer cylinder 110 is cylindrical and fixed axially and horizontally on the bracket 4 . A cylinder cover 108 , a reflux condensing device interface 111 , a vent 116 , a feed inlet 117 , a pressure gauge interface 114 , a temperature sensor interface 105 and a liquid discharge outlet 113 are arranged on the outer cylinder body. A cylinder cover 108 is arranged on a bottom surface of the cylinder, and the cylinder cover 108 is connected with the outer cylinder 110 through a quick-opening bolt 101 , and a viewing window 1...

Embodiment 2

[0033] Example 2 Alcoholysis Separation of Waste Polyester-Cotton Textiles

[0034] 1. Raw materials:

[0035] Alcoholysis agent: ethylene glycol;

[0036] Catalyst: sodium carbonate;

[0037] Waste polyester-cotton blended fabric: polyester 87 / cotton 13 (only waste polyester-cotton tops with fusible interlining and metal attachments removed);

[0038] The weight ratio of the alcoholysis agent to the waste polyester-cotton blended fabric is 6:1;

[0039] The amount of catalyst added is 0.4‰ of the weight of waste polyester-cotton blended fabric.

[0040] 2. Use the device described in Example 1 to carry out alcoholysis separation, and the specific steps are as follows:

[0041]I. Put the waste polyester-cotton blended fabric into the inner cylinder, add the alcoholysis agent and catalyst into the outer cylinder through the feed port, and close the cylinder cover;

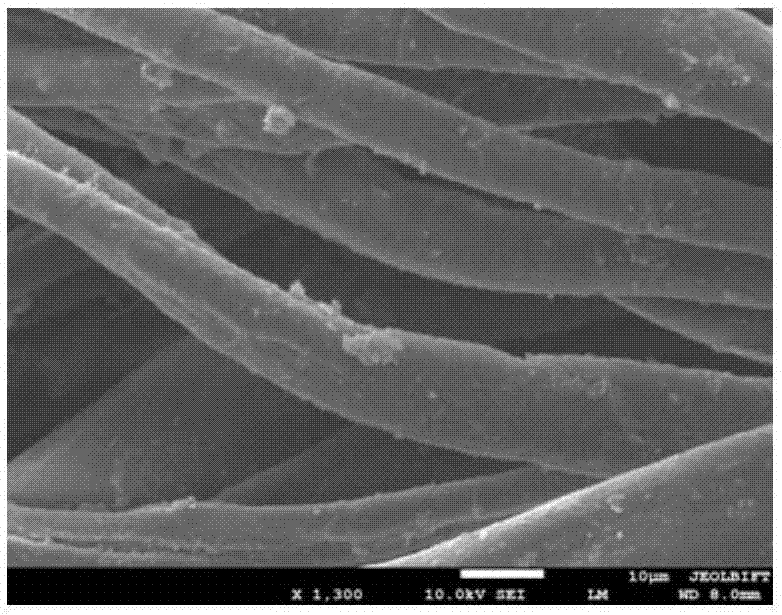

[0042] II. Turn on the motor and heating device, so that the inner cylinder rotates forward and reverse, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com