Patents

Literature

32results about How to "Realize continuous recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

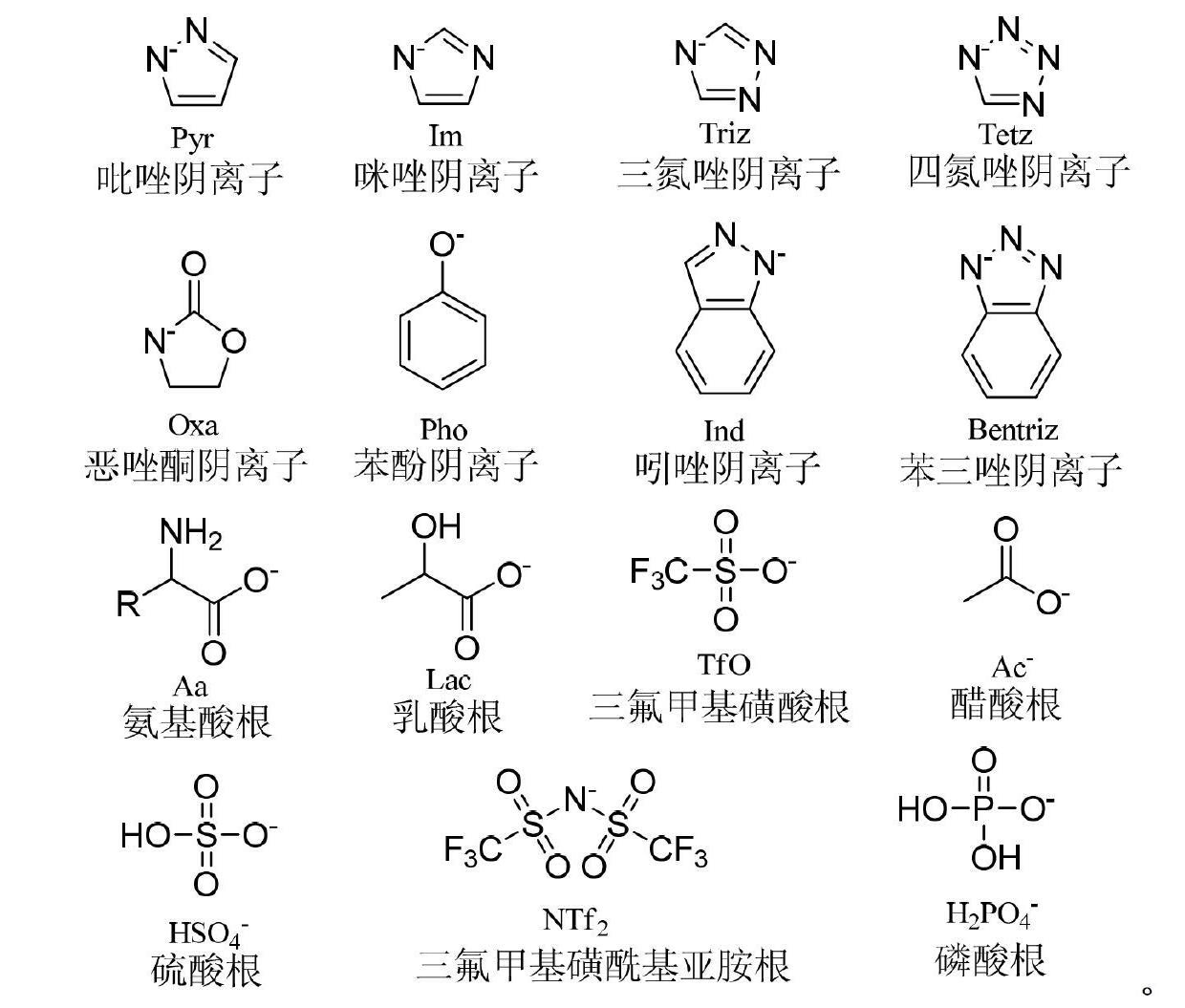

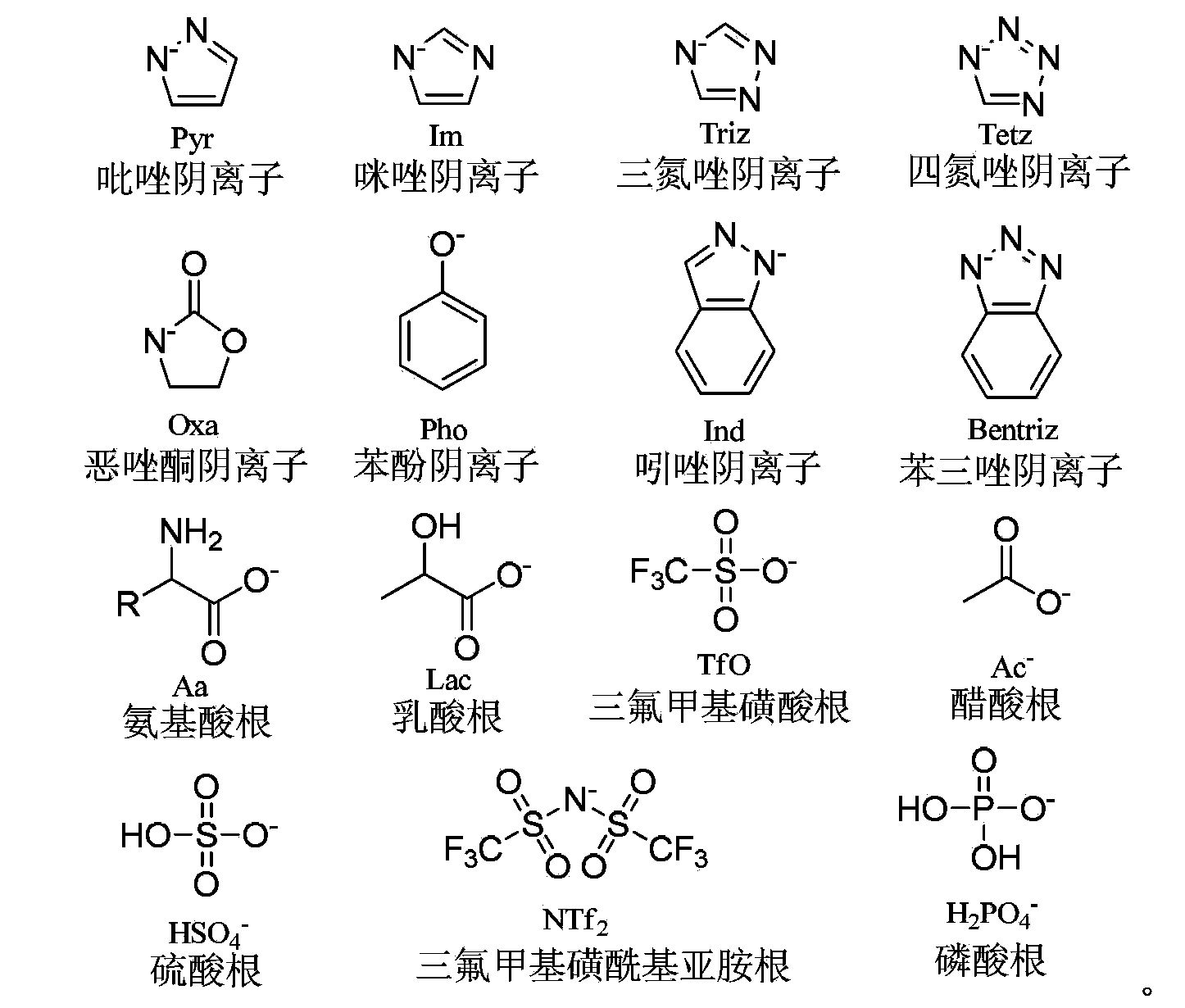

Method for absorbing and separating light hydrocarbons from dry gas or industrial tail gas by utilizing ionic liquid

ActiveCN104277880ARealize multiple recyclingNo pollutionDispersed particle separationLiquid hydrocarbon mixture recoveryAlkaneSolubility

The invention discloses a method for absorbing and separating light hydrocarbons from dry gas or industrial tail gas by utilizing an ionic liquid. The ionic liquid or a mixed solvent of the ionic liquid and a molecular solvent is taken as an absorbent to be in contact with the dry gas or the industrial tail gas, an absorption liquid containing the light hydrocarbons is obtained by absorption and the light hydrocarbons are further obtained by desorption and separation; and the light hydrocarbons are alkanes or olefins which mainly contain C2-C4. The invention provides the method for absorbing and separating the light hydrocarbons from the dry gas or the industrial tail gas by utilizing the ionic liquid. The ionic liquid or the mixed solvent of the ionic liquid and the molecular solvent is taken as the absorbent, an absorption-desorption method is adopted for recovery and separation of the light hydrocarbons, and the absorbent has very high solubility of the light hydrocarbons and separation selectivity, so that efficient separation and recovery of the light hydrocarbons can be realized and the highest comprehensive recovery rate can achieve 98.5%.

Owner:ZHEJIANG UNIV

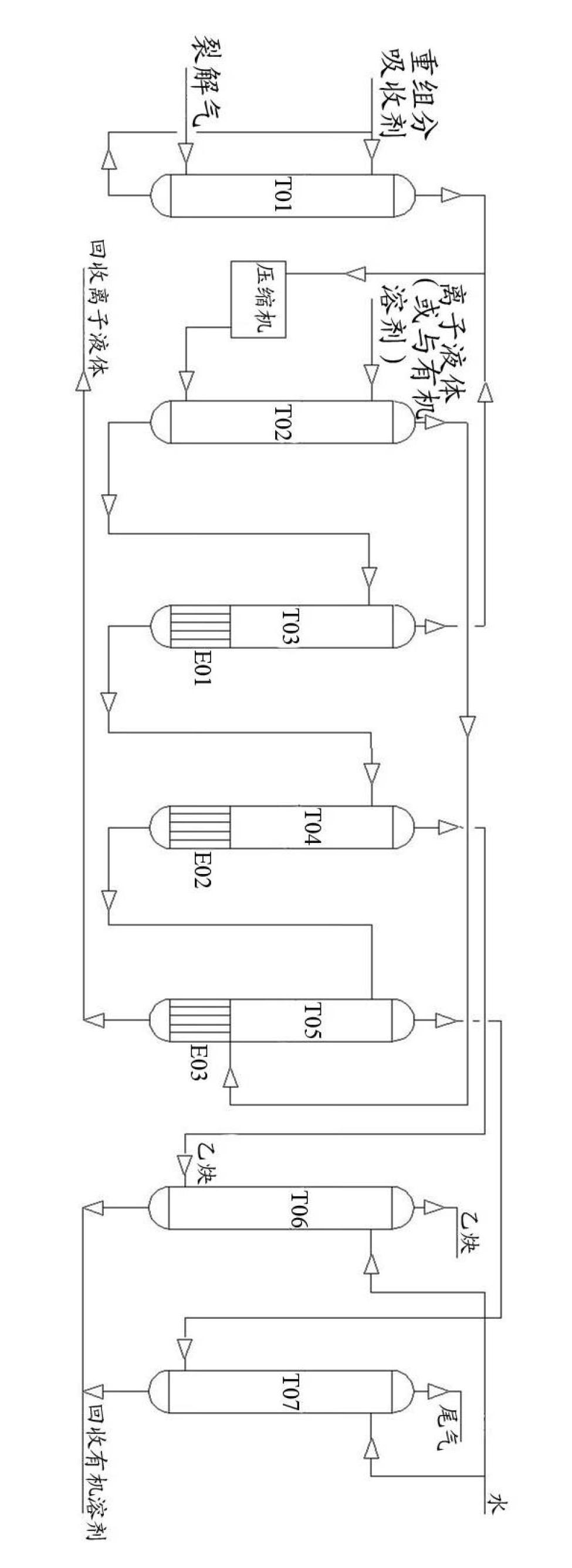

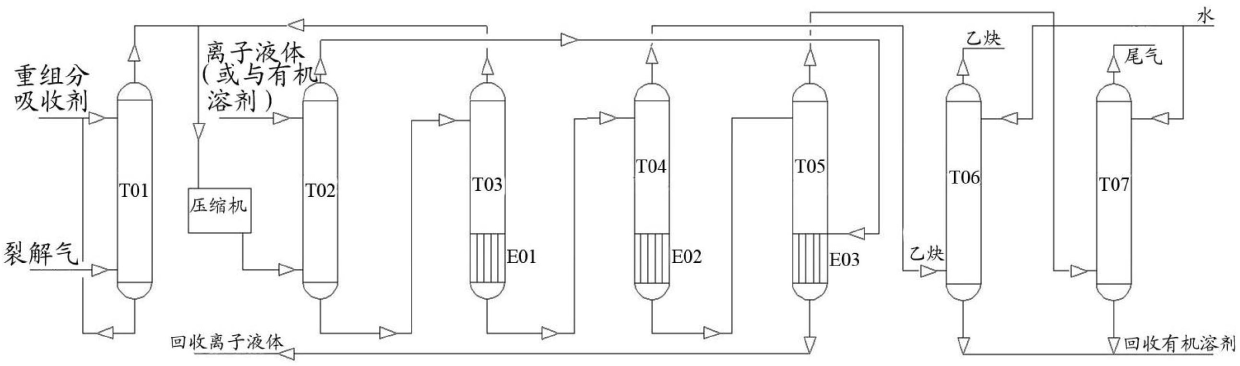

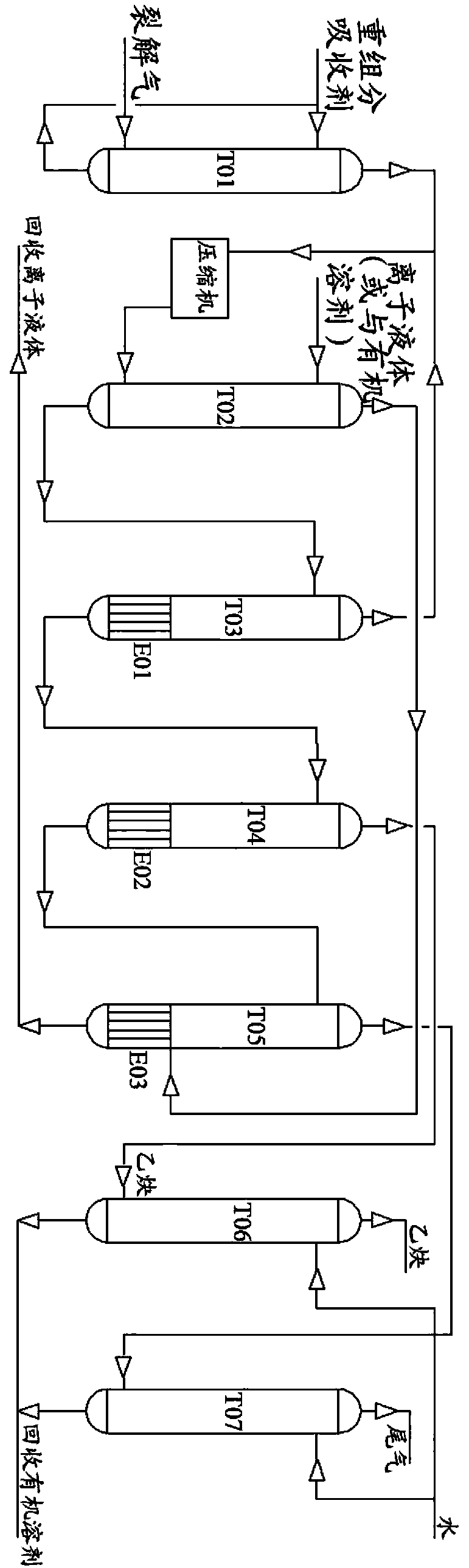

Separating preparation method of acetylene by absorbing pyrolysis gas with ionic liquid

ActiveCN102675028ARealize multiple recyclingImprove thermal stabilityAbsorption purification/separationBulk chemical productionEnvironmental resistanceDesorption

The invention discloses a separating preparation method of acetylene by absorbing pyrolysis gas with ionic liquid, which comprises the following steps of: absorbing heavy components in pyrolysis gas by heavy component absorbent, sequentially absorbing the pyrolysis gas under high pressure by taking the ionic liquid or the mixed solution consisting of the ionic liquid and organic solvent as absorbent and adopting an absorption-desorption method, and carrying out split reduction and warming desorption on the preheated absorption liquid, to desorb the light components, the acetylene and the high alkyne, so as to obtain the high-purity acetylene in a separation way. The method has the characteristics of being high in separation efficiency, less in solvent energy consumption, safe, environment-friendly, suitable for the industrial production, and the like.

Owner:XINJIANG YUEHETAI CHEM TECH CO LTD

Method for absorbing and separating ammonia gas from ammonia-containing exhaust gas

ActiveCN106474873AImprove solubilityHigh separation selectivityGas treatmentDispersed particle separationSolubilityDesorption

The invention discloses a method for absorbing and separating ammonia gas from ammonia-containing exhaust gas. The method comprises the following steps: adopting a hybrid eutectic solvent as an absorbent, the solvent contacting with ammonia-containing exhaust gas to obtain an ammonia-absorbing liquid, and then conducting the desorption of the ammonia-absorbing liquid to obtain ammonia gas. The hybrid eutectic solvent consists of three components, weak acid compounds, salt compounds and additives. The invention adopts the method of absorption and desorption by using the hybrid eutectic solvent as the absorbent to recover and separate ammonia gas. The absorbent has high ammonia solubility and separation selectivity, and can achieve the efficient separation and recovery of ammonia gas.

Owner:ZHEJIANG UNIV

Method for absorbing and separating light hydrocarbon from dry gas or industrial tail gas

ActiveCN106474869ALow saturated vapor pressureThe synthesis method is simpleDispersed particle separationSolubilityAlkane

The invention discloses a method for absorbing and separating light hydrocarbon from dry gas or industrial tail gas. The method comprises the following steps: allowing a deep eutectic solvent used as an absorbent to contact with the dry gas or the industrial tail gas, carrying out absorption so as to obtain an absorption solution containing the light hydrocarbon, and subjecting the absorption solution to desorption and separation so as to obtain the light hydrocarbon, wherein the light hydrocarbon mainly contains C2-C4 alkane or olefin. According to the invention, the deep eutectic solvent is used as the absorbent, and an absorption-desorption method is adopted to recycle and separate the light hydrocarbon, wherein the absorbent has significantly high light hydrocarbon solubility and separation selectivity, so highly-efficient separation and recycling of the light hydrocarbon can be realized.

Owner:ZHEJIANG UNIV

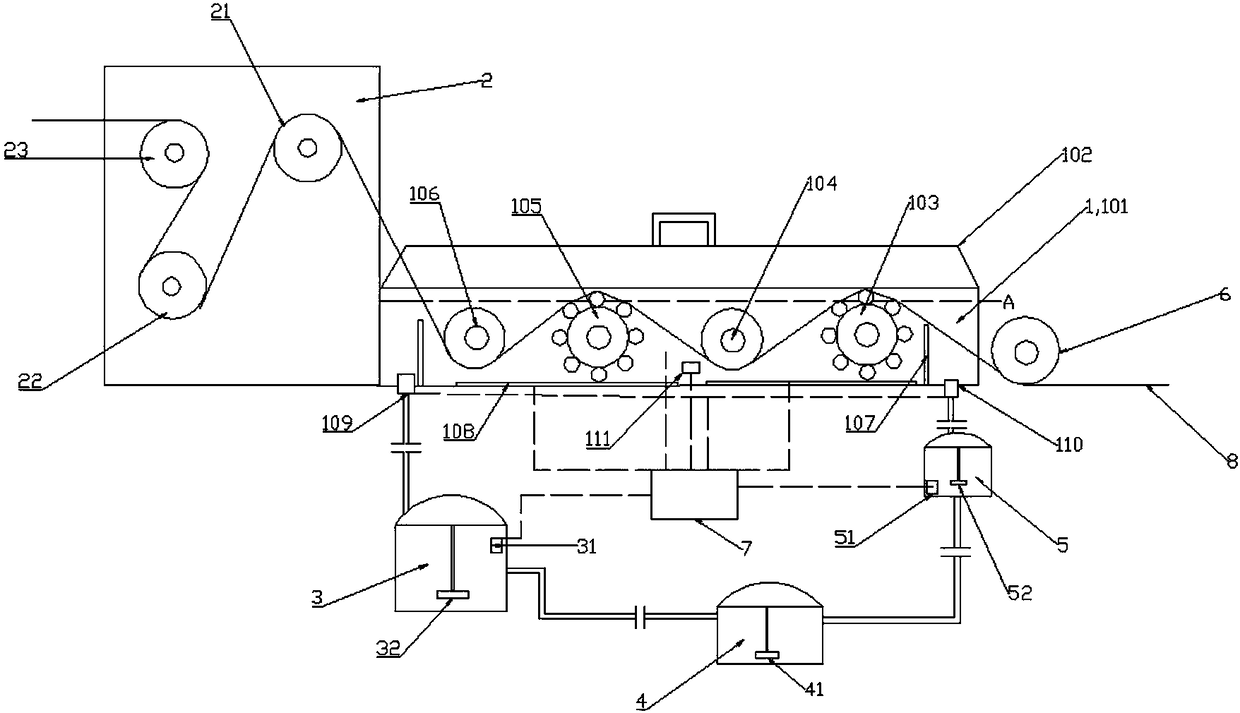

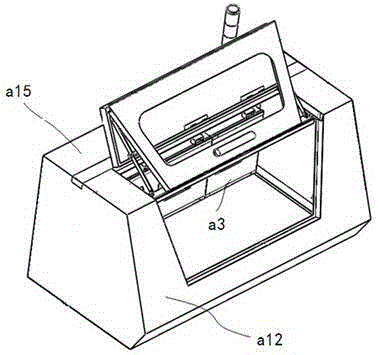

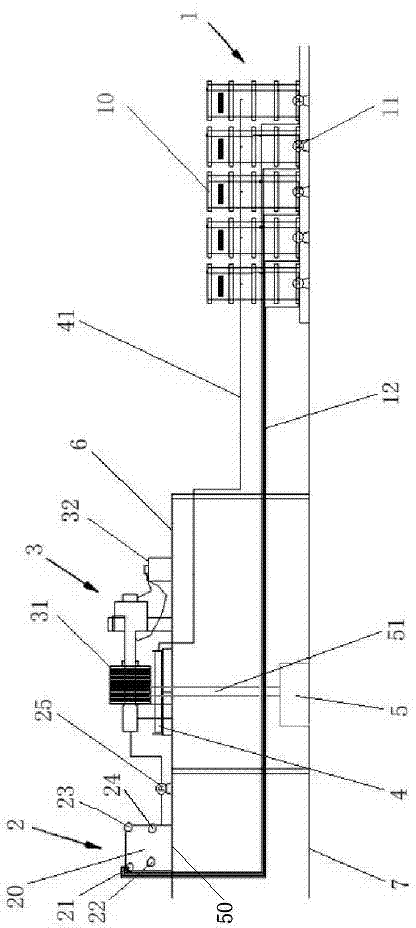

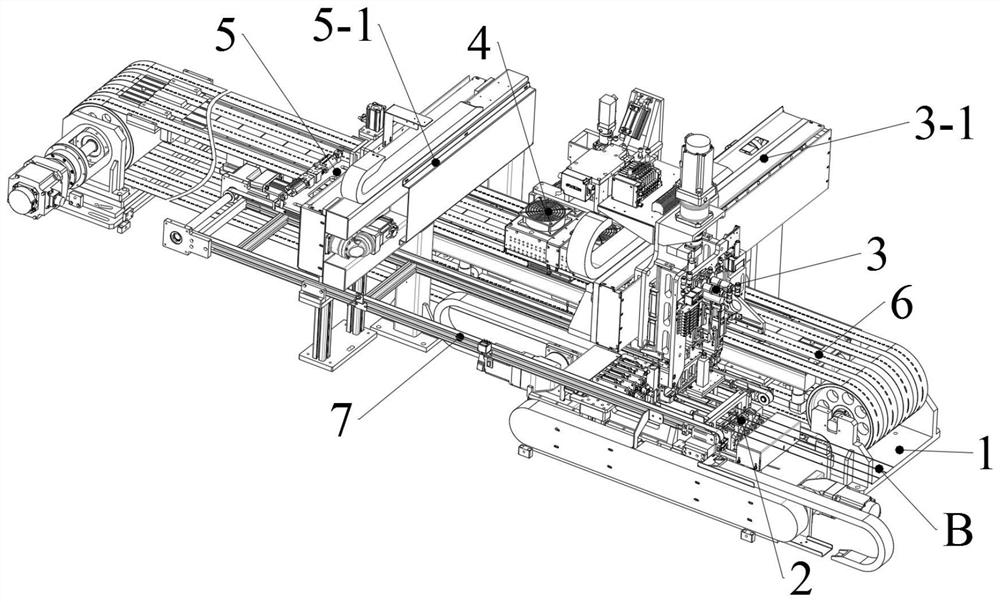

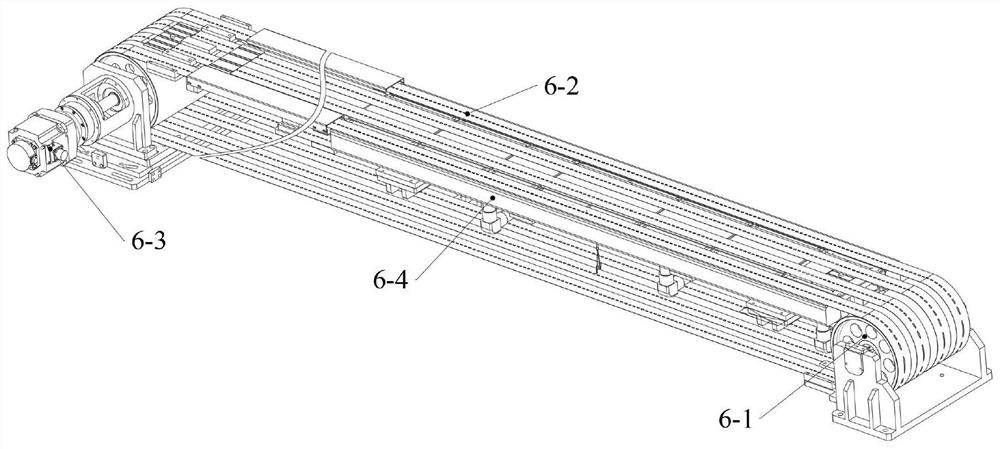

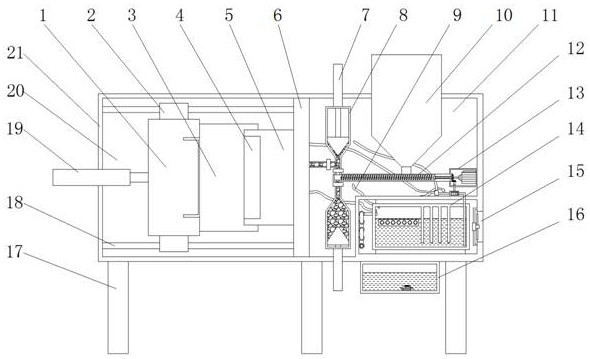

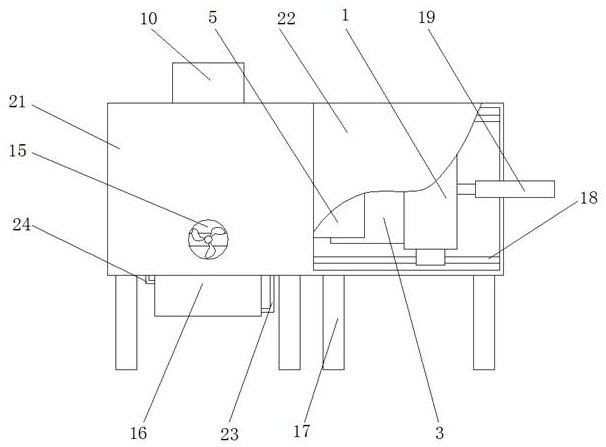

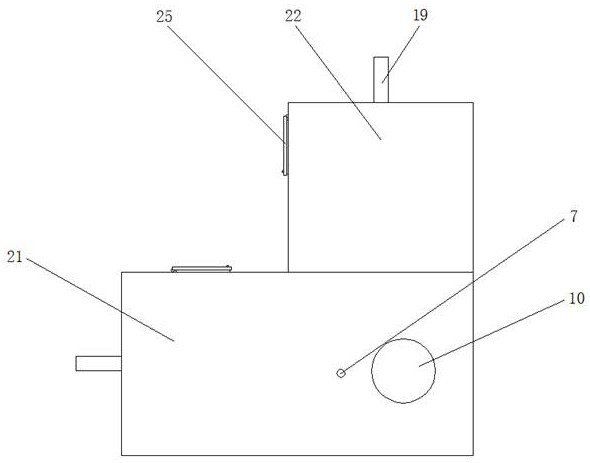

IBC solar cell string light welding device and welding method thereof

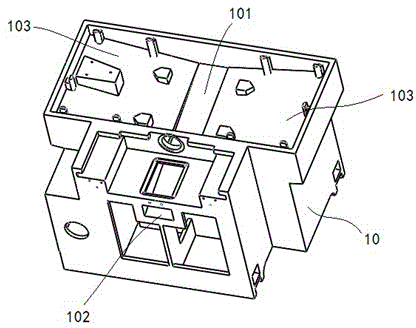

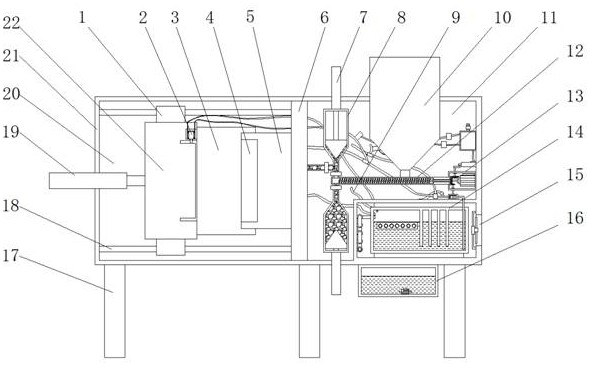

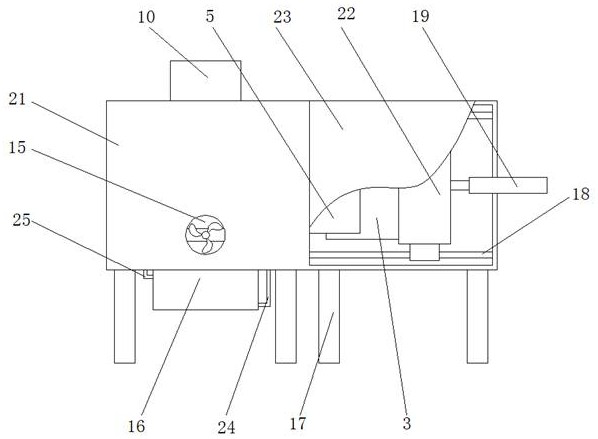

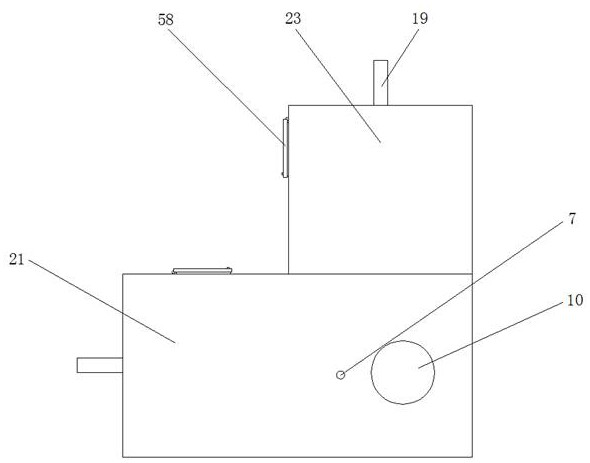

ActiveCN111203661AAvoid displacementImprove yield rateWelding/cutting auxillary devicesAuxillary welding devicesElectrical batterySolar cell

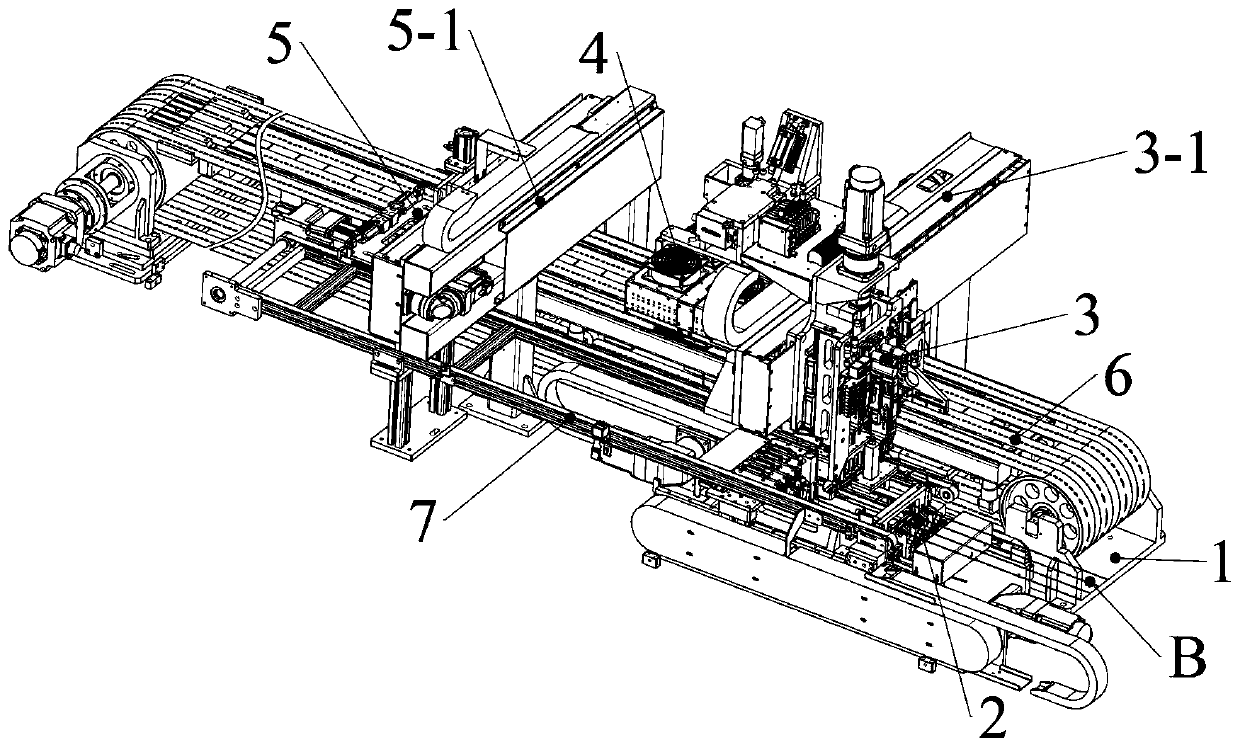

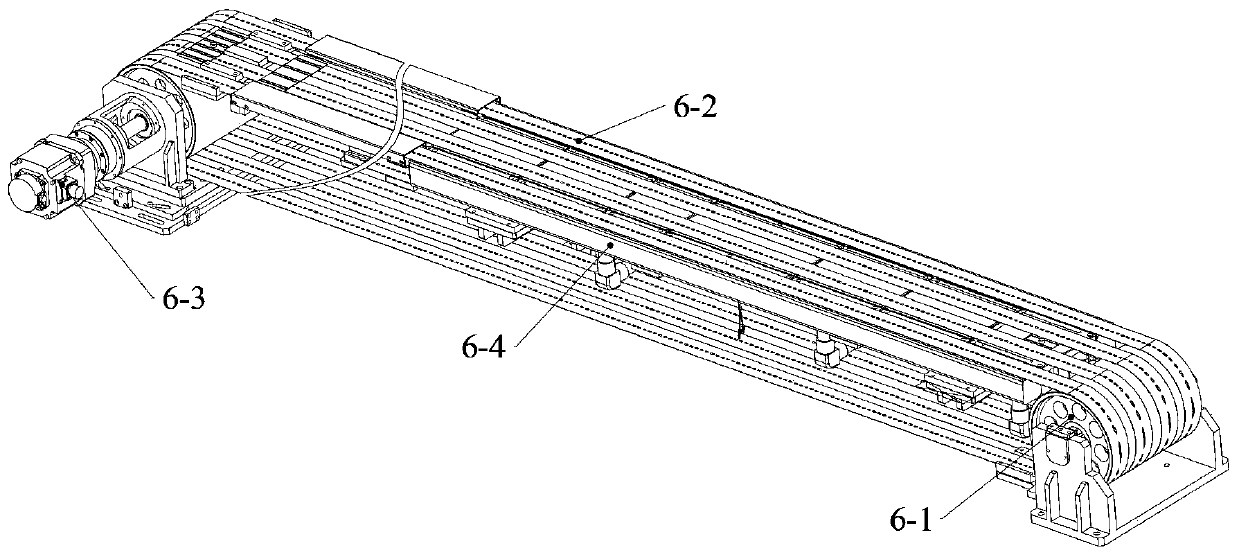

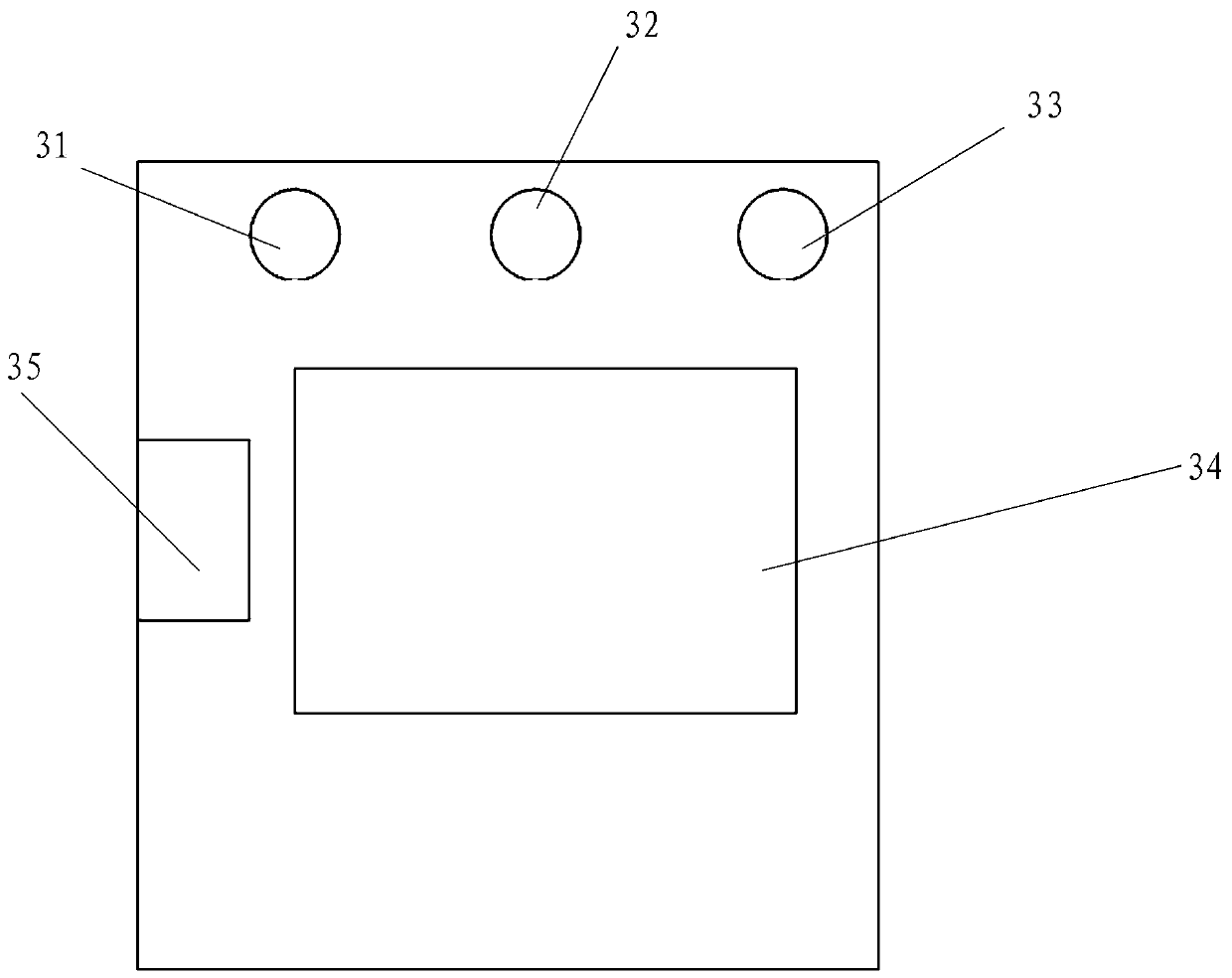

The invention discloses an IBC solar cell string light welding device and a welding method thereof. Compared with a conventional series welding machine through which the position of a metal wire is fixed through a rear battery piece, IBC batteries cannot achieve the effect, and a net pressing clamp is needed to perform covering fixing. The light welding device comprises a rack, a welding strip feeding device, a welding strip transferring device, a light welding device body, a clamp returning device, a battery conveyor, a clamp conveyor and a pressing positioning clamp; the clamp conveyor is located on one side of the battery conveyor; the welding strip feeding device is located below the output end of the clamp conveyor; the welding strip transferring device is located above the input endof the battery conveyor and the output end of the clamp conveyor; and the welding strip transferring device, the light welding device body and the clamp returning device are sequentially arranged in the conveying direction of the battery conveyor. According to the device and the method, welding strips are pressed by the pressing positioning clamp while being placed, so that the welding strip are prevented from shifting in the conveying process, and the yield of battery strings is greatly improved.

Owner:HANGZHOU COMFIRMWARE TECH CO LTD

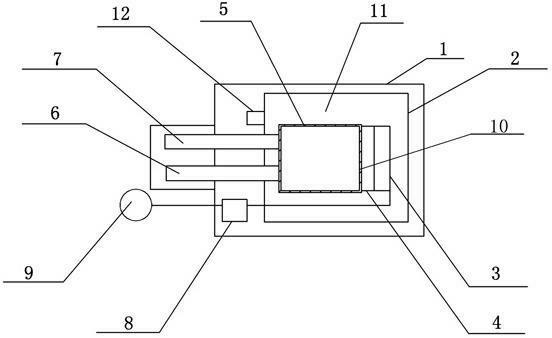

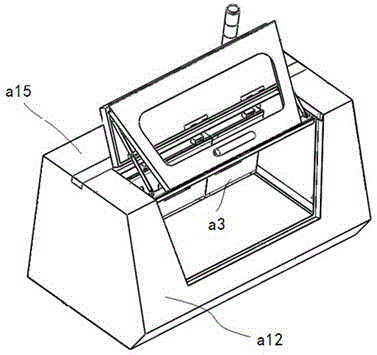

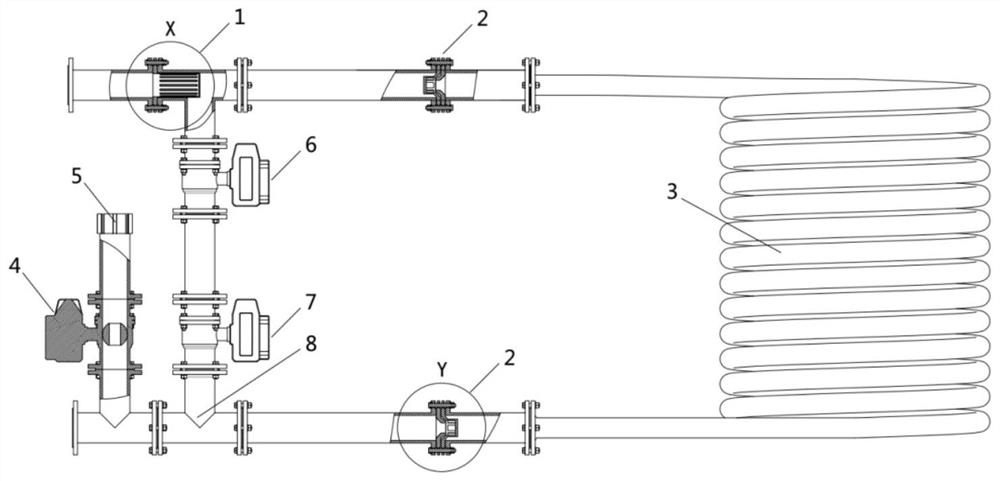

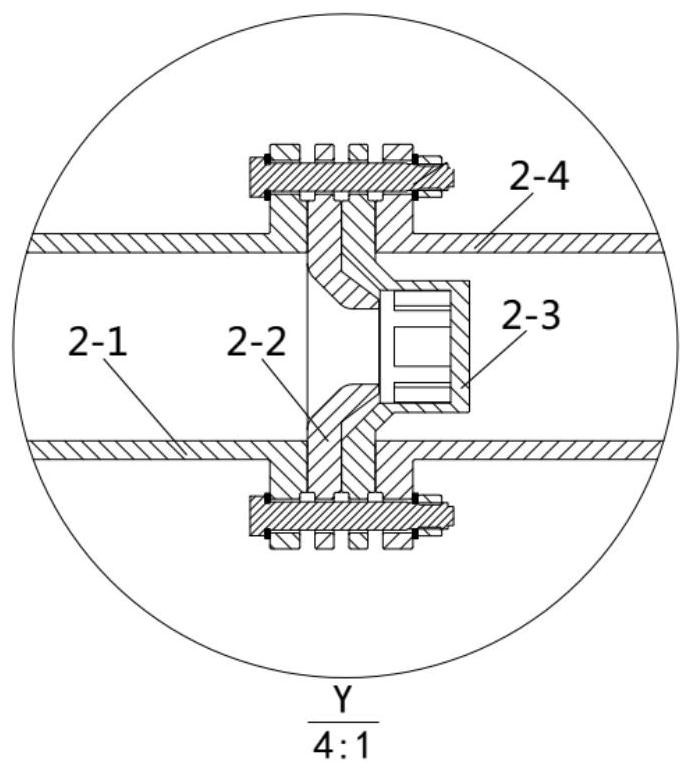

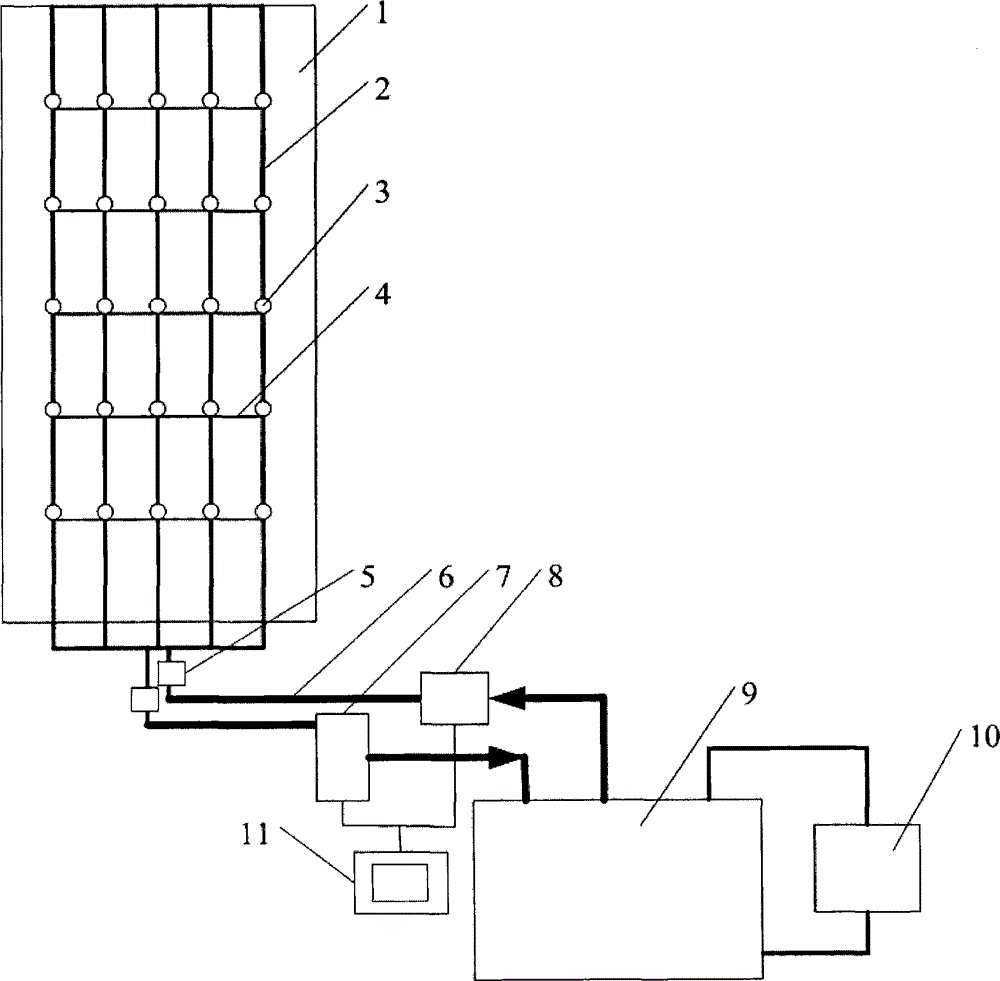

High-temperature superconducting surface radio-frequency receiving coil for magnetic resonance imaging and operation method thereof

InactiveCN102680924ALower self-resistanceHigh Q valueMeasurements using magnetic resonanceHeat conductingRadio frequency

The invention discloses a high-temperature superconducting surface radio-frequency receiving coil for magnetic resonance imaging and an operating method thereof. The high-temperature superconducting surface radio-frequency receiving coil for magnetic resonance imaging comprises a housing (1), a vacuum housing (2) and a liquid nitrogen circulating system, wherein the vacuum housing (2) is arranged in the housing (1); a high-temperature superconducting surface coil (3) is arranged in the vacuum housing (2); a low-temperature heat conducting body (4) is arranged at one end of the high-temperature superconducting surface coil (3); a liquid nitrogen tank (5) is arranged at one end of the low-temperature heat conducting body (4); an inlet pipe (6) and an outlet pipe (7) are arranged on the liquid nitrogen tank (5); a pre-amplifier (8) is arranged inside the housing (1); a signal receiving device (9) is arranged at one end of the pre-amplifier (8); and a vacuum chamber (11) is arranged between the liquid nitrogen tank (5) and the vacuum housing (2). With the structure, the high-temperature superconducting surface radio-frequency receiving coil has the advantages that the resistance is reduced; furthermore, the Q value of the coil is increased, the imaging signal-to-noise ratio is increased, and the signal receiving performance is enhanced.

Owner:TIME MEDICAL JIANGSU

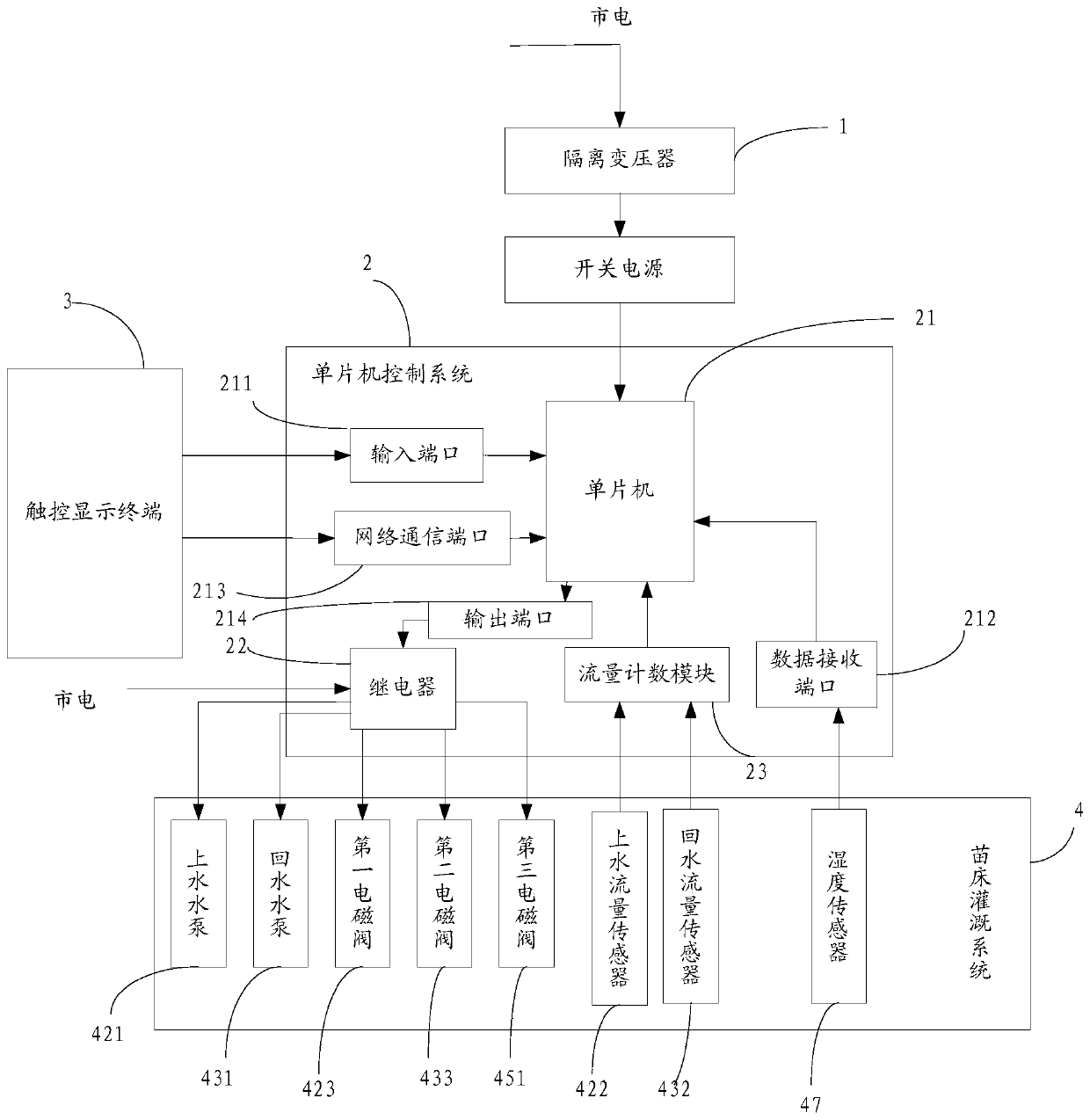

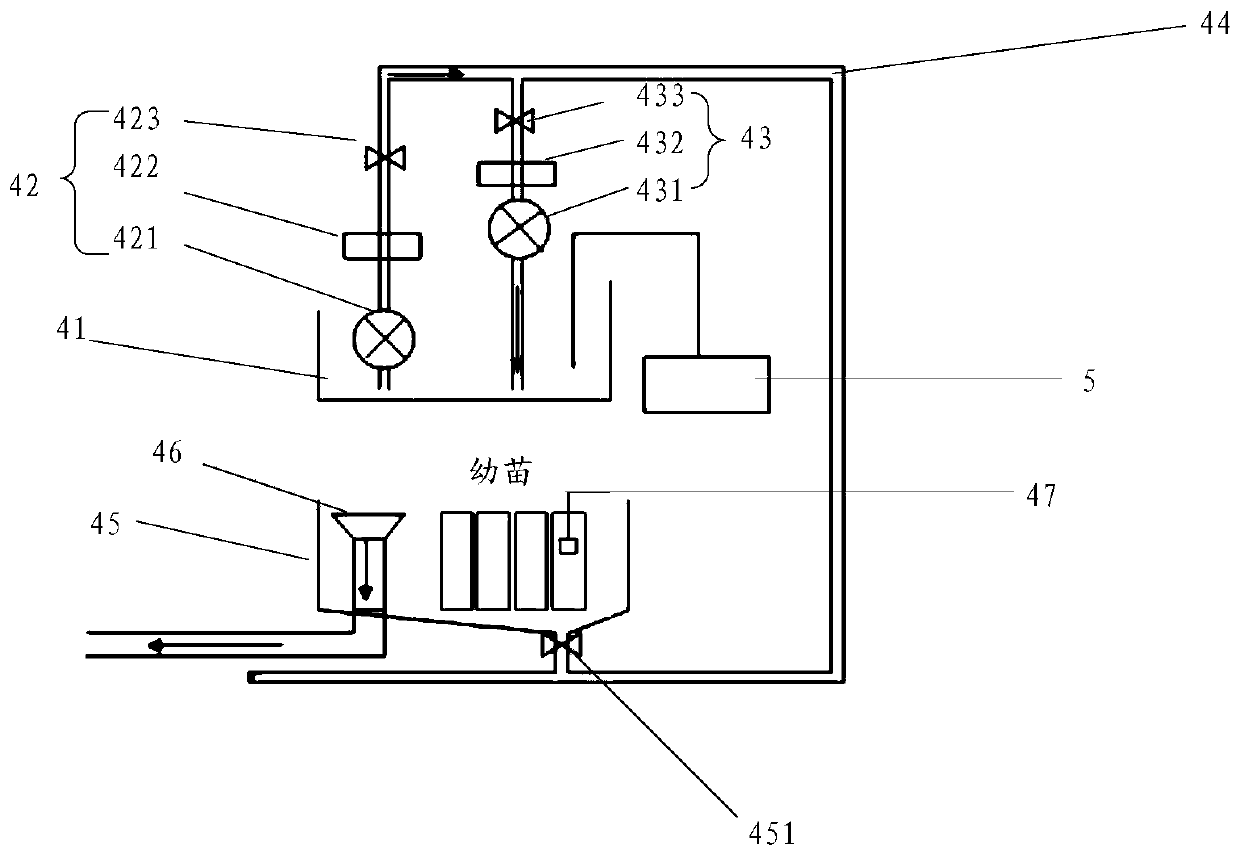

Citrus seedling tide irrigation system

PendingCN111418477AReduce lossesReduce manual operationsProgramme controlComputer controlAgricultural scienceAutomatic control

The invention discloses a citrus seedling tide irrigation system. The citrus seedling tide irrigation system comprises an isolation transformer, a single-chip microcomputer control system, a touch control display terminal and a seedbed irrigation system; the input end of the isolation transformer is connected with the commercial power through a main switch, and the output end of the isolation transformer is connected with the single-chip microcomputer control system through a switch power supply; the touch control display terminal is in communication with the single-chip microcomputer controlsystem through a local area network or a public network, and can display the working parameters of the seedbed irrigation system in real time; and the single-chip microcomputer control system activelyor automatically controls the working state of the seedbed irrigation system according to an instruction from the touch control display terminal or a preset irrigation program. The single-chip microcomputer control system is adopted to control the seedbed seedling without needing PLC wiring, the technology is simple, deployment is easy, and the system is very suitable for middle and small-scale seedling occasions.

Owner:SOUTH CHINA AGRI UNIV

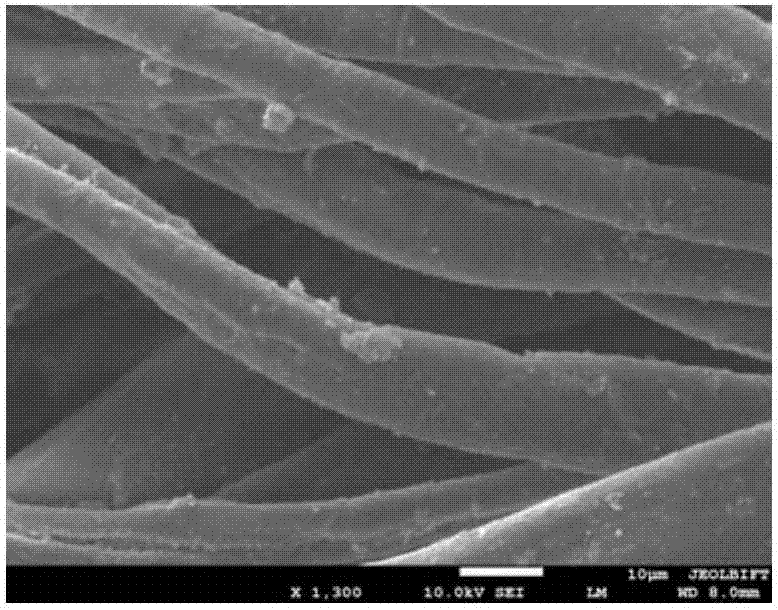

Oiling device for spinning fiber production

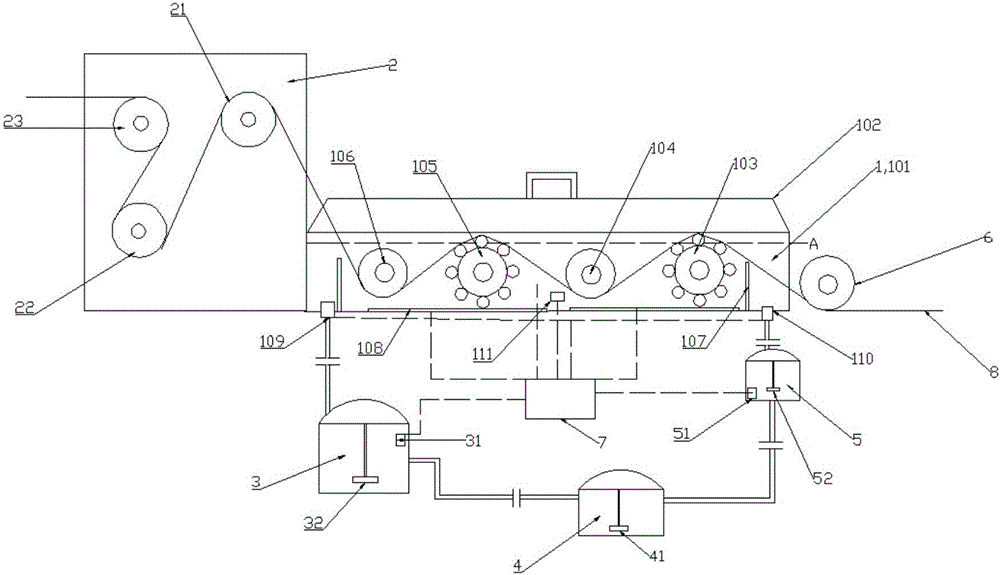

ActiveCN106591972AEnhanced effect of dipping fiber towsWell mixedFilament manufactureFilament/thread formingFiber bundleCarbon fibers

The invention discloses an oiling device for spinning fiber production and belongs to the technical field of carbon fiber production equipment. The oiling device comprises an oiling trough and an oiling agent circulating system communicated with an inlet and an outlet of the oiling trough. The oiling agent circulating system comprises a preparation tank communicated with the inlet of the oiling tank, an overflowing tank communicated with the outlet of the oiling tank and a stock solution treatment tank communicated with the preparation tank and the overflowing tank. A plurality of flower rolls and a plurality of smooth rolls are mounted in the oiling trough in parallel alternately, each of the flower rolls consists of a central roll body and 8-25 peripheral roll bodies evenly distributed around the central roll body, and the diameter of each central roll body is 7-15 times of that of each peripheral roll body. The oiling device for spinning fiber production has the advantages that the flower rolls arranged in the oiling trough are used for stirring the oiling agent in the oiling trough to accelerate relative movement between the oiling agent and fiber bundles, so that the effect that the oiling agent permeates into the fiber bundles is improved; the oiling agent in the oiling trough is mixed more uniformly.

Owner:HARBIN TIANSHUN CHEM TECH DEV CO LTD

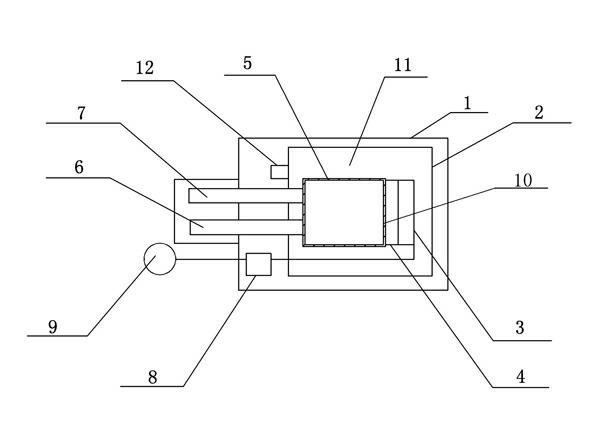

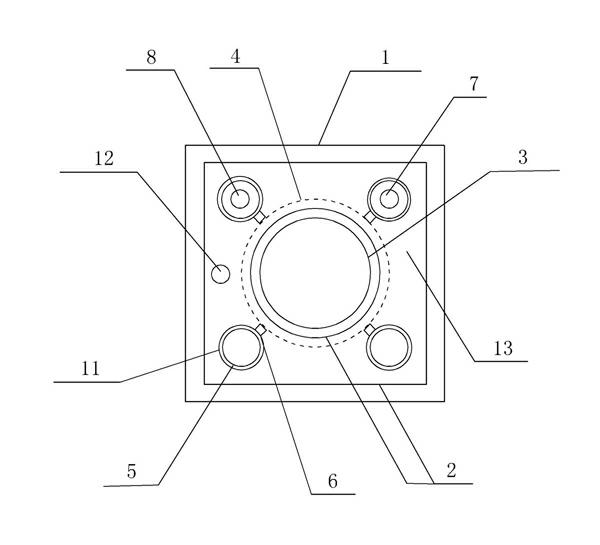

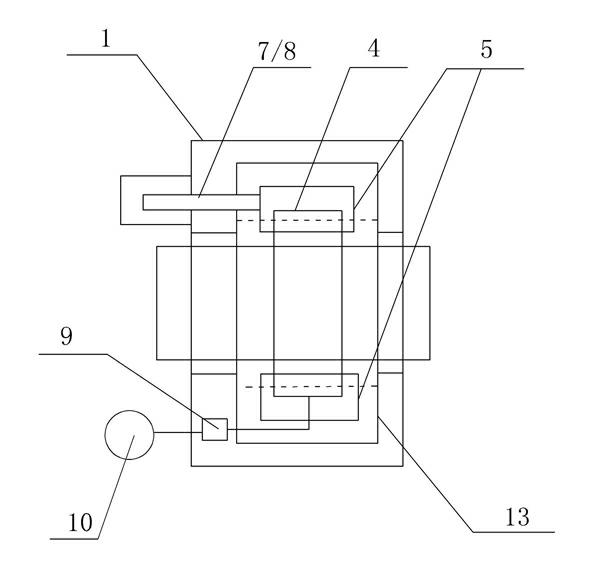

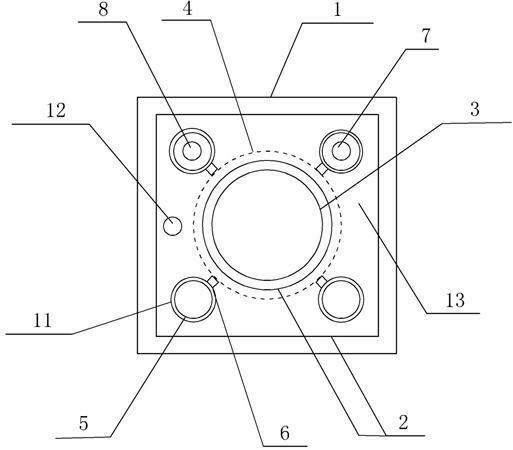

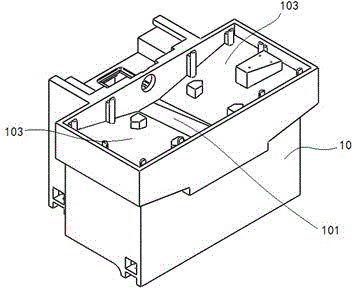

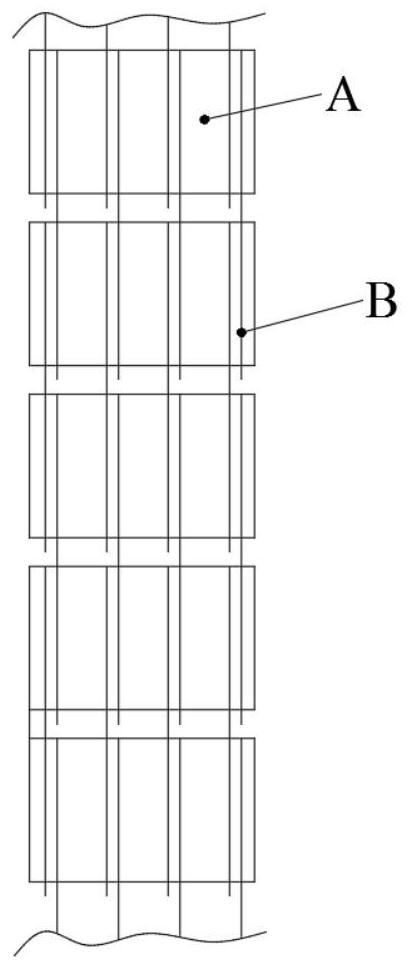

High-temperature superconductivity knee joint radio frequency receiving coil device used for magnetic resonance imaging

InactiveCN102680923AReduce use costRealize continuous recyclingMeasurements using magnetic resonanceElectrical resistance and conductanceAudio power amplifier

The invention discloses a high-temperature superconductivity knee joint radio frequency receiving coil device used for magnetic resonance imaging, which comprises a shell (1), a vacuum cover (2) and a liquid nitrogen circulating system, wherein the shell (1) is provided with a through hole; the vacuum cover (2) is arranged in the shell (1); a high-temperature superconductivity knee joint coil (4) is arranged in the vacuum cover (2); the periphery of the high-temperature superconductivity knee joint coil (4) is provided with at least three liquid nitrogen tanks (5); a low-temperature heat conduction plate (6) is arranged between among the at least three liquid nitrogen tanks (5) and the high-temperature superconductivity knee joint coil (4); each liquid nitrogen tank (5) is provided with at least one liquid nitrogen liquid inlet pipe (7) and a liquid nitrogen outlet pipe (8); the lower end of the shell (1) is provided with a preamplifier (9); and one end of the preamplifier (9) is provided with a signal receiving device (10). After the above structure is adopted, the self resistance of the coil is reduced, so that a Q value of the coil is increased and an imaging signal-to-noise ratio is increased, and the signal receiving performance is improved.

Owner:TIME MEDICAL JIANGSU

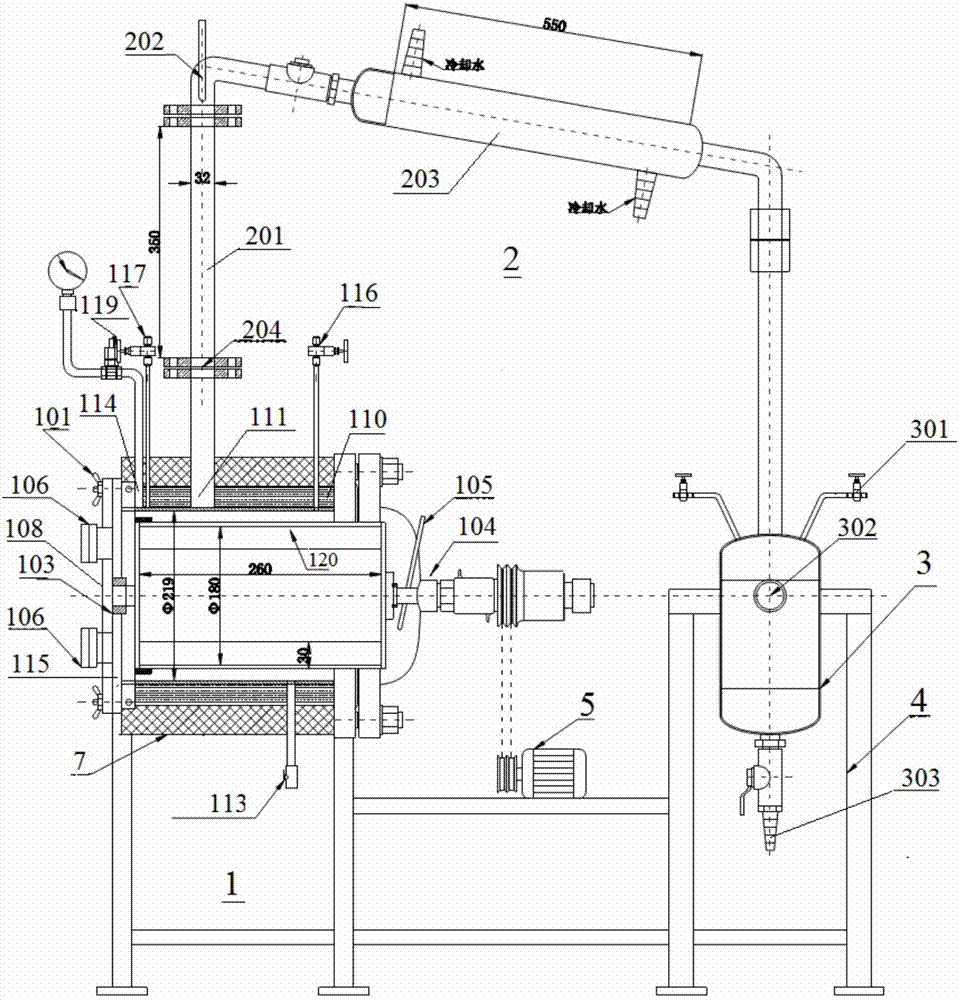

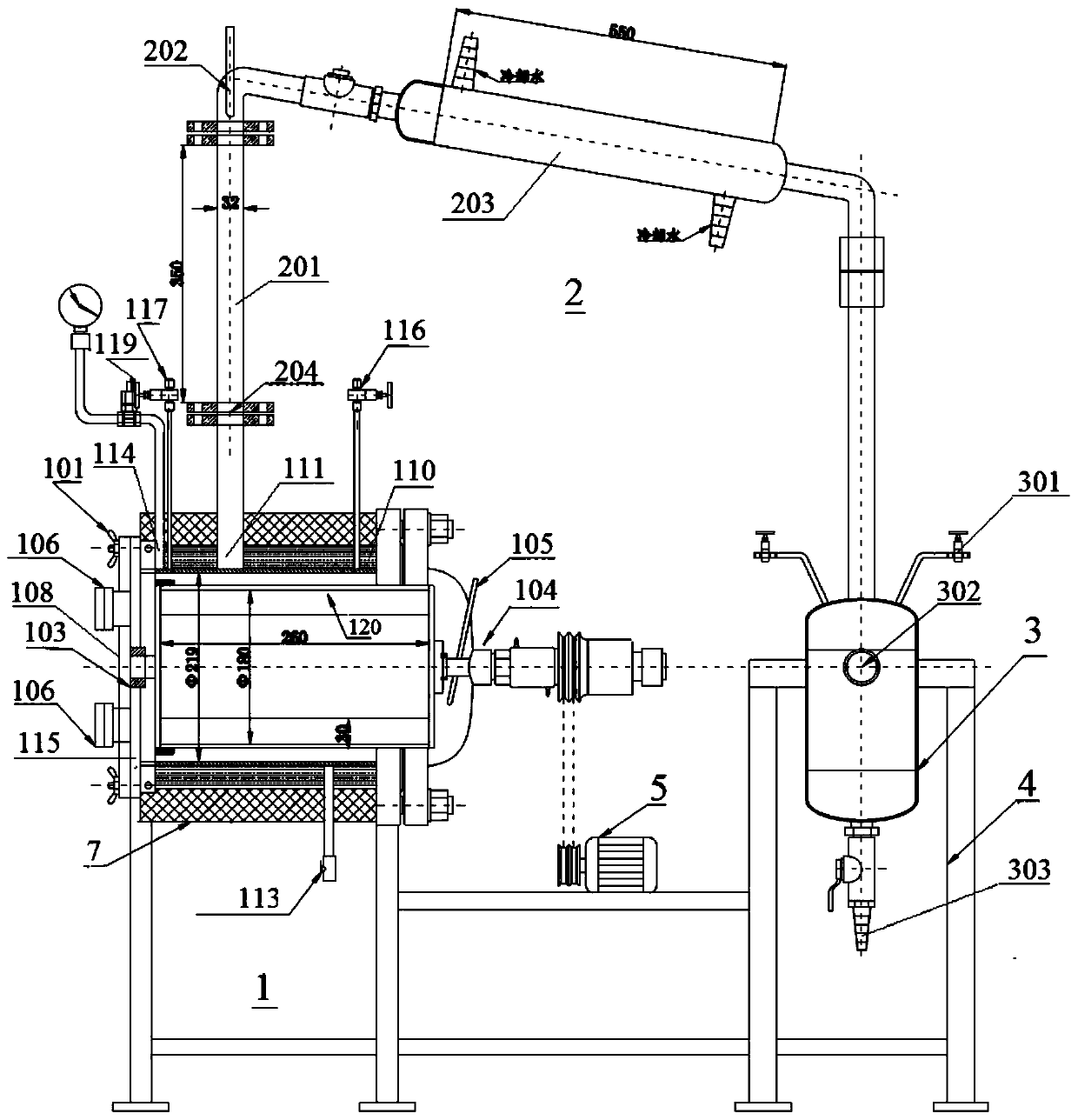

Device for separating components of waste polyester-cotton blended fabric

PendingCN107321050AAvoid damageImprove separation efficiencyPlastic recyclingFiltration circuitsRefluxYarn

The invention relates to a device for separating components of waste polyester-cotton blended fabric. The device is a horizontal rotary alcoholysis separation device and consists of an outer barrel and an inner barrel; the outer barrel is connected with a vacuum reflux condensing device; heating elements and a heat insulation layer are arranged at the periphery of the barrel wall of the outer barrel; the inner barrel is horizontally arranged in the outer barrel along the axial direction; through holes or meshes are formed in the barrel wall of the inner barrel; the inner barrel is provided with a vacuum / micro-pressure dual-purpose mechanical seal rotating shaft, and the rotating shaft passes through the outer barrel and is connected with a motor; the rotating shaft is driven by the motor, so that the rotating action of the inner barrel can be realized in a micro-pressure or vacuum state; the tail end of the vacuum reflux condensing device is connected with a collecting tank; the collecting tank is connected with a vacuum apparatus. When the device is used for carrying out alcoholysis on the waste polyester-cotton blended fabric, the process of stirring is omitted, so that the problem of property damage caused by winding of rest cotton yarns during stirring can be solved; the problems that an alcoholysis agent is left over in the rest cotton yarns, discharge is difficult to realize, and the like are solved; therefore, after the device is adopted, the components of the waste polyester-cotton blended fabric are efficiently and conveniently separated and recovered.

Owner:温州天成纺织有限公司

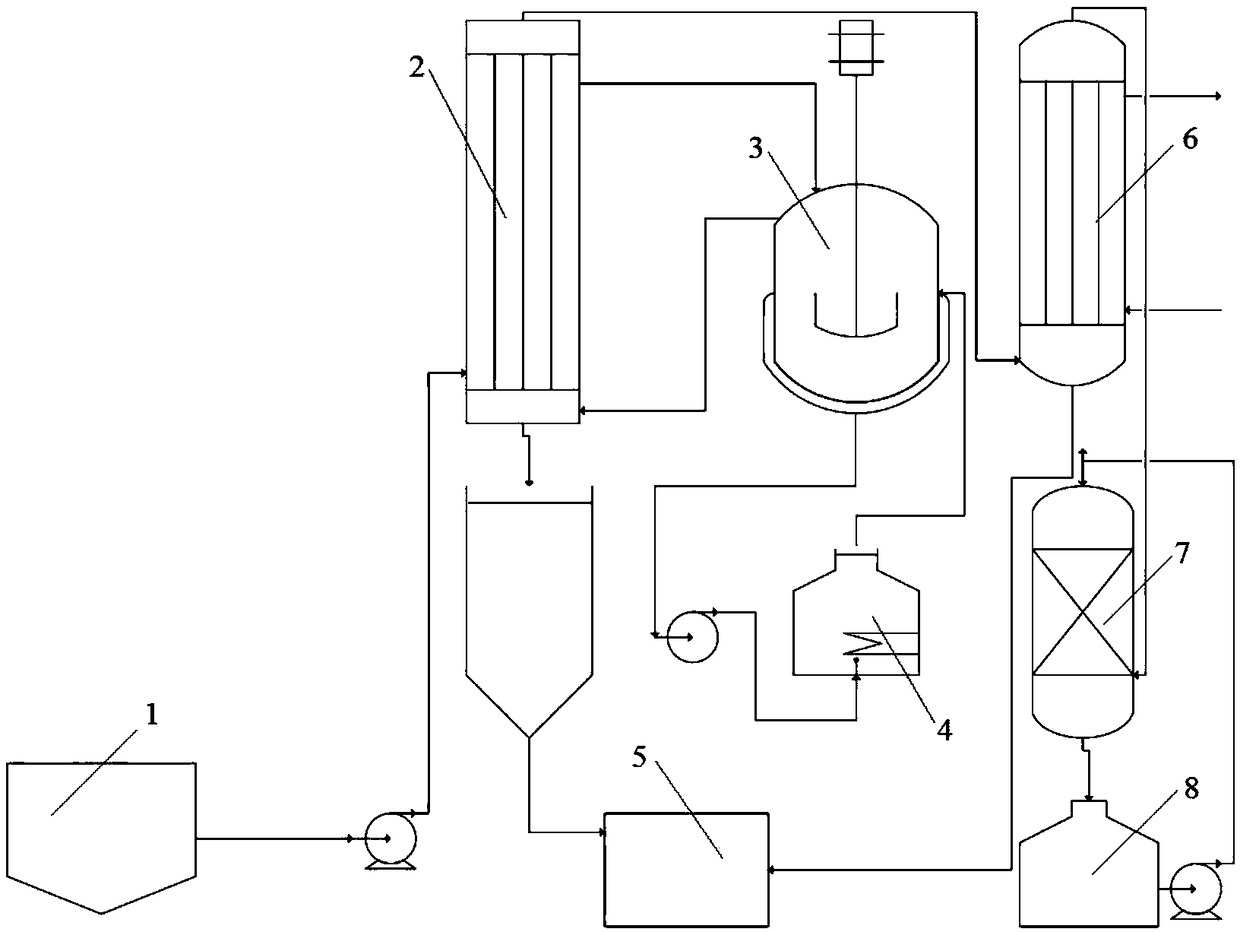

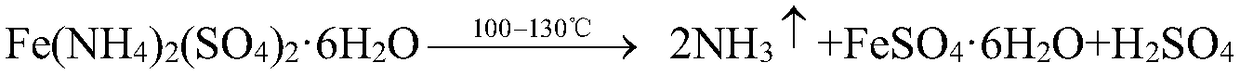

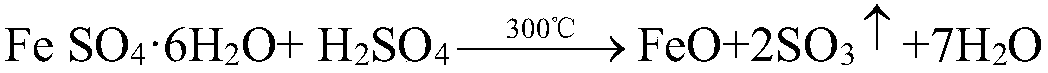

Process method for preparing ammonia water and sulfuric acid from ammonium sulfate solution

InactiveCN109052334ARealize diversified useRealize continuous recyclingSulfur compoundsAmmonia preparation/separationCatalytic methodDecomposition

The invention belongs to the field of chemical waste disposal, and relates to a process method for preparing ammonia water and sulfuric acid from an ammonium sulfate solution. The process method comprises: (1) dissolving solid ammonium sulfate into the ammonium sulfate solution; (2) adding a catalyst into a reaction kettle and heating, and spraying the ammonium sulfate solution into the reaction kettle; (3) performing heat exchange on released vapor and ammonia gas when reaction temperature reaches 100 DEG C - 130 DEG C, thus obtaining the ammonia water; (4) when the temperature of the reaction kettle drops to 130 DEG C or below, stopping spraying the ammonium sulfate solution, continuing to heat to 300 DEG C - 350 DEG C and releasing sulfur trioxide gas, and then performing preliminary condensation and absorption with dilute sulfuric acid in sequence, thus obtaining the sulfur acid. The process method realizes low-temperature decomposition of ammonium sulfate at 400 DEG C or below bya solid-liquid catalytic method and achieves resource utilization of industrial waste with a simple process, high operability, energy saving and environmental protection.

Owner:NINGXIA TIANYUAN MANGANESE LIMITED

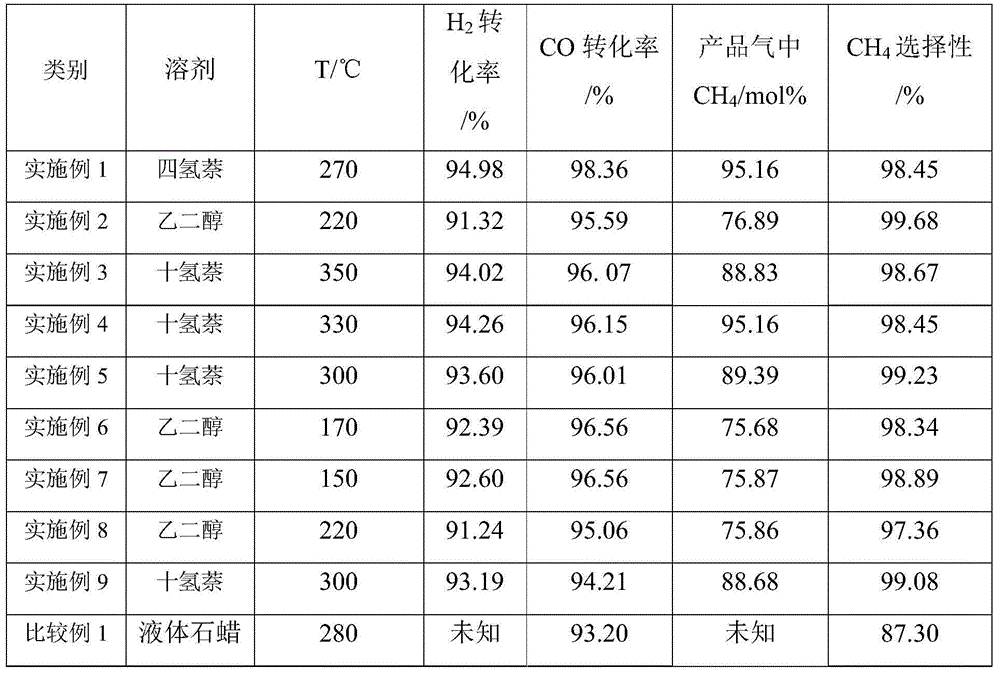

Application of hydrogen-donor solvent and surfactant in methanation reaction

InactiveCN104557389AStabilize system thermal balanceAvoid reunionHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsSolventReaction rate

The invention discloses application of a hydrogen-donor solvent and a surfactant in a methanation reaction. An active hydrogen-donor solvent and the surfactant and the surfactant are added into a slurry bed reactor; a methanation catalyst is used for performing a methanation reaction under the effects of the active hydrogen-donor solvent and the surfactant, wherein the amount of added surfactant is 1% to 12.5% of the volume of the hydrogen-donor solvent; the ratio of the catalyst to the hydrogen-donor solvent is (0.002-0.01)g to 1ml; the hydrogen-donor solvent comprises tetrahydronaphthalene, decahydronaphthalene or glycol. The application disclosed by the invention has the advantages of being simple in process, high in reaction rate and suitable for the slurry bed reactor.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

An oiling device for spinning fiber production

ActiveCN106591972BEnhanced effect of dipping fiber towsWell mixedFilament manufactureFilament/thread formingCarbon fibersFiber bundle

Owner:HARBIN TIANSHUN CHEM TECH DEV CO LTD

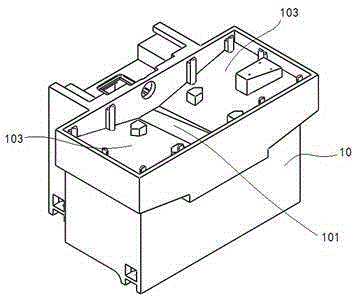

Circulation oil supply system and inner circle slicing machine system with same

ActiveCN104097271AContinuous dischargeEasy to achieve recyclingWorking accessoriesMaintainance and safety accessoriesMachining systemOil mist

The invention provides a circulation oil supply system and an inner circle slicing machine system with the same. The circulation oil supply system comprises a cutting oil recycling device, a first purifying device, a first oil supply device, an oil mist treating device, a second purifying device and a second oil supply device. The cutting oil recycling device, the first purifying device and the first oil supply device are sequentially communicated with a cutter head mounting space to form a first circulation oil supply circuit, the oil mist treating device, the second purifying device and the second oil supply device are sequentially communicated with the cutter head mounting space to form a second circulation oil supply circuit, the first circulation oil supply circuit is used for recycling and purifying cutting oil in the cutter head mounting space and supplying oil for the cutter head mounting space, the second circulation oil supply circuit is used for recycling, condensing and purifying oil mists in the cutter head mounting space and supplying oil for the cutter head mounting space, the oil mist treating device comprises a one-way gas channel, the one-way gas channel is communicated with the cutter head mounting space and is provided with a plurality of vertical sections and horizontal sections, each two adjacent vertical sections are communicated with each other by the corresponding horizontal section, condensation parts with a plurality of gaps or channels or tiny holes are arranged in the horizontal sections, the bottommost portions of the vertical sections are lower than the lowest positions of the horizontal sections, and the vertical sections are communicated with the corresponding purifying device.

Owner:BEIJING DINGCHEN HIGH TECH

Efficient and energy-saving injection mold with core pulling function

The invention discloses an efficient and energy-saving type injection mold with the core pulling function. The efficient and energy-saving type injection mold with the core pulling function comprises a material tank and a shell. The material tank is arranged at one end of the top of the shell, the bottom end of the material tank extends to the middle height position in the shell, and a partition plate is vertically welded to the position, on one side of the material tank, in the shell. A feeding chamber is formed on the side, close to the material tank, of the partition plate in the shell. According to the efficient and energy-saving type injection mold with the core pulling function, a pair of piston cylinders for containing molten materials in a reciprocating manner is symmetrically connected to a main material conveying pipe, and a set of fixed mold and movable mold for injection molding are arranged in the shell and a connecting box, so that the fixed mold and the movable mold at the shell and the connecting box can be used for alternately and intermittently machining and producing plastic parts; and the main conveying pipe can continuously convey the materials, continuous feeding of the main conveying pipe cannot block a pipeline, the injection molding efficiency is improved, the volume of the materials needing to be injected in each time of injection molding production is easier to control, and the product quality is higher.

Owner:FOSHAN MASTER TOYS

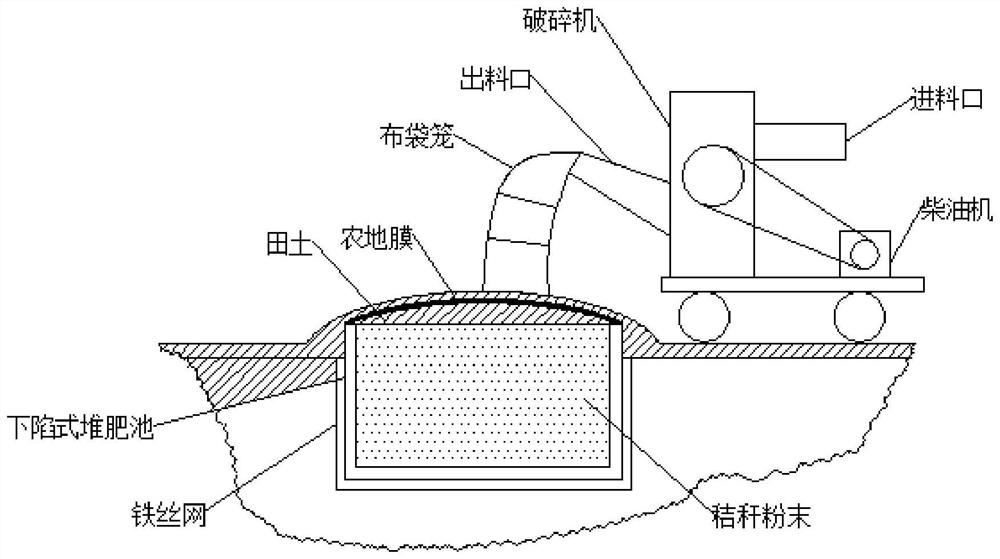

Method for returning crop stalks to field

PendingCN113692855AEasy to recycleReduce usageBio-organic fraction processingCrop conditionersSoil sciencePlastic mulch

The invention discloses a method for returning crop stalks to a field. The method comprises the following steps of S1, digging a sunken composting pool in a crop harvesting season; S2, smashing the harvested crop stalks, pouring the smashed crop stalks into the sunken composting pool, spreading the crop stalks until the thickness is 0.8 m-1m, covering the crop stalks with a layer of field soil with the thickness of 5 cm, compacting, and watering until the crop stalk powder and the field soil are wet to obtain a pretreated fertilizer pile; S3, covering the surface of the pretreated fertilizer pile with 1 layer-2 layers of agricultural mulching films, and standing to enable the crop stalk powder to be subjected to water-logged composting in the sunken composting pool until the crop stalk powder becomes a decomposed fertilizer; S4, when the next harvesting season begins, removing the agricultural mulching films, directly taking the decomposed fertilizer, and uniformly scattering the decomposed fertilizer into the field after the crops are harvested and before ploughing; and S5, repeating the steps S2-S4. According to the method for returning the crop stalks to the field, the harm to soil and crops caused by traditional direct crop stalk returning is avoided, waste gas and waste water generated during water-logged compost can be prevented from leaking to pollute the environment, the quality of the soil and the crops can be improved, the implementation is simple, and continuous circulation can be realized.

Owner:安徽捷思新材料科技有限公司

A temporary plugging ball impact grinding test device and test method for shale gas horizontal well fracturing

ActiveCN111272588BEffective test deformationSimple processMaterial strength using repeated/pulsating forcesInvestigating abrasion/wear resistanceThermodynamicsGrinding test

The invention discloses a temporary plugging ball impact grinding test device for shale gas horizontal well fracturing, which includes a circulating pump, a liquid tank, a sensor, and an impact grinding test part. Standpipe, accelerated collision sub, spiral grinding oil pipe, solid capture and block short connection, the ball blocking return riser is installed downstream of the ball throwing riser, and its two ends are respectively connected with the entrance of the accelerated collision sub and the solid capture and block The short joints are connected, and the outlet of the solid capture and blocking short joint is connected with the liquid tank. The present invention simulates the influence of the equipment and the manifold on the temporary plugging ball by designing the impact and grinding test device, and at the same time designs a cycle experiment structure to meet the long-term test requirements, and can effectively test the deformation of the temporary plugging ball in the manifold. Material performance, optimization of ball-dropping temporary plugging and diversion equipment and technology, and improvement of fracturing efficiency provide indoor experimental basis.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for Separating Components of Waste Polyester-Cotton Blended Fabrics

ActiveCN107308905BAvoid damageImprove separation efficiencyPlastic recyclingPressure vessel componentsPolyesterYarn

Owner:温州天成纺织有限公司

Circulating oil supply system and internal circle slicer system with the same

ActiveCN104097271BRealize continuous recyclingEasy to scaleWorking accessoriesMaintainance and safety accessoriesCutting oilOil mist

The invention provides a circulating oil supply system and an internal circular slicer system with the circulating oil supply system, including a cutting oil recovery device, a purification device and an oil supply circuit which are sequentially communicated with the cutter head installation space to form a first circulating oil supply circuit. The device, and the oil mist treatment device, the purification device and the oil supply device that communicate with the cutterhead installation space in sequence to form the second circulating oil supply circuit, the first circulating oil supply circuit is used to recover and purify the cutting oil in the cutterhead installation space And supply oil to the cutter head installation space, the second circulating oil supply circuit is used to recover, condense, purify the oil mist in the cutter head installation space and supply oil to the cutter head installation space, the oil mist treatment device includes a connection with the cutter head installation space A one-way gas channel, the gas channel has several vertical sections and a horizontal section that sequentially connects two adjacent vertical sections, a condensing element with several gaps or channels or micropores is provided in the horizontal section, and the vertical section The bottom is lower than the lowest position of the horizontal section, and the vertical section communicates with the purification device.

Owner:BEIJING DINGCHEN HIGH TECH

A method for desulfurization and light hydrocarbon removal from natural gas by using ionic liquid

ActiveCN104263442BRealize multiple recyclingNo pollutionGaseous fuelsDispersed particle separationSolvent moleculeDesorption

The invention discloses a method for desulfurizing and removing light hydrocarbons from natural gas by using ionic liquids. Firstly, ionic liquids or mixed solvents of ionic liquids and molecular solvents are used as absorbents to contact natural gas to absorb sulfides, light hydrocarbons and carbon dioxide in natural gas. , to obtain the absorption liquid and the remaining tail gas; the light hydrocarbon mainly contains C 2 ~C 4 Alkanes or alkenes; and then the absorption liquid is desorbed in two stages, and the light hydrocarbons and sulfides are desorbed in turn, and the absorbent obtained by desorption is recycled. The invention provides a method for removing sulfur and light hydrocarbons from natural gas by using ionic liquid or a mixed solvent composed of ionic liquid and molecular solvent as absorbent. The designed ionic liquids with long alkyl side chains in the anions have high selective solubility of hydrogen sulfide, light hydrocarbons and other gases, which are superior to conventional ionic liquids, thus achieving efficient removal of sulfides and recovery of light hydrocarbons.

Owner:ZHEJIANG UNIV

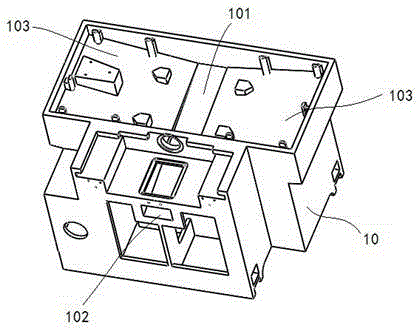

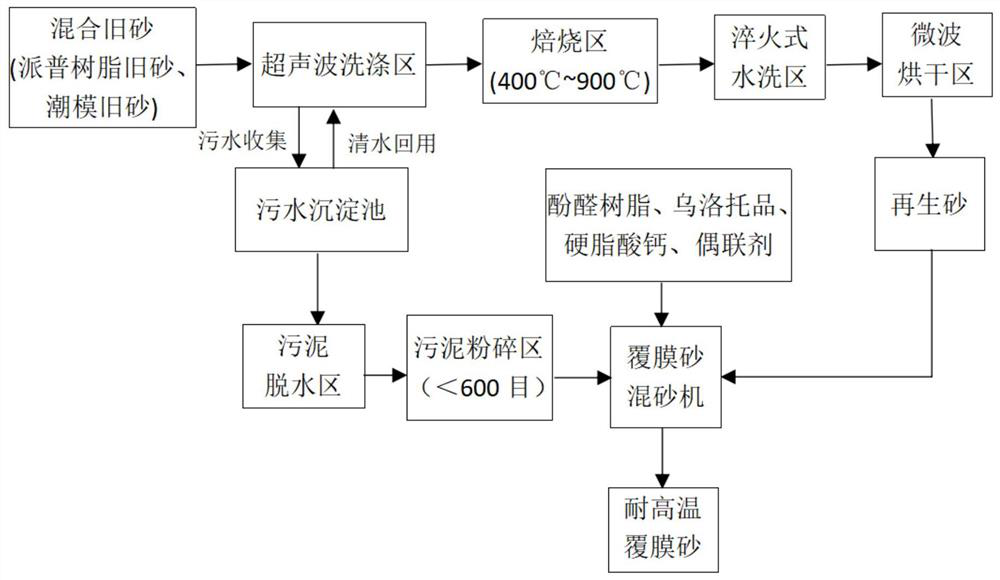

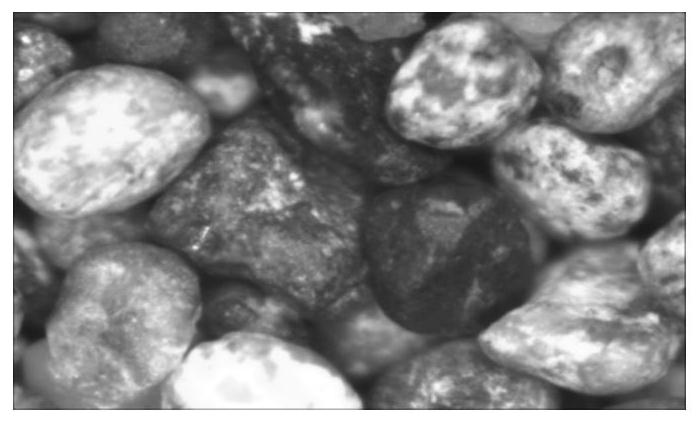

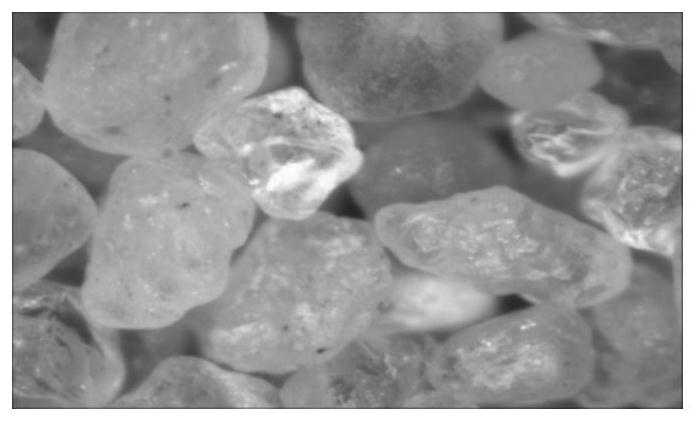

A method for regenerating sand for large steel castings and high temperature resistant coated sand prepared from the regenerated sand

ActiveCN112275996BImprove performanceAchieving a circular economyFoundry mouldsMould handling/dressing devicesMetallurgySludge

The invention provides a method for regenerating sand for large-scale steel castings. The stubborn residual film on the surface of the old sand can be removed through the regeneration methods of ultrasonic cleaning, roasting to remove organic matter and quenching and leaching, and the performance of the regenerated sand is equivalent to that of the original sand. Even better than raw sand. Afterwards, the regenerated sand is used as aggregate, and the sludge generated during the regeneration process is used as a high-temperature-resistant auxiliary agent to produce high-temperature-resistant coated sand, realizing a circular economy of zero-emission old sand regeneration. The invention also provides the high-temperature-resistant coated sand prepared from the regenerated sand, whose high-temperature resistance performance is greatly improved due to the addition of regenerated sludge.

Owner:YANCHENG RENCHUANG SAND IND TECH CO LTD

Separating preparation method of acetylene by absorbing pyrolysis gas with ionic liquid

ActiveCN102675028BRealize multiple recyclingImprove thermal stabilityAbsorption purification/separationBulk chemical productionOrganic solventDesorption

The invention discloses a separating preparation method of acetylene by absorbing pyrolysis gas with ionic liquid, which comprises the following steps of: absorbing heavy components in pyrolysis gas by heavy component absorbent, sequentially absorbing the pyrolysis gas under high pressure by taking the ionic liquid or the mixed solution consisting of the ionic liquid and organic solvent as absorbent and adopting an absorption-desorption method, and carrying out split reduction and warming desorption on the preheated absorption liquid, to desorb the light components, the acetylene and the high alkyne, so as to obtain the high-purity acetylene in a separation way. The method has the characteristics of being high in separation efficiency, less in solvent energy consumption, safe, environment-friendly, suitable for the industrial production, and the like.

Owner:XINJIANG YUEHETAI CHEM TECH CO LTD

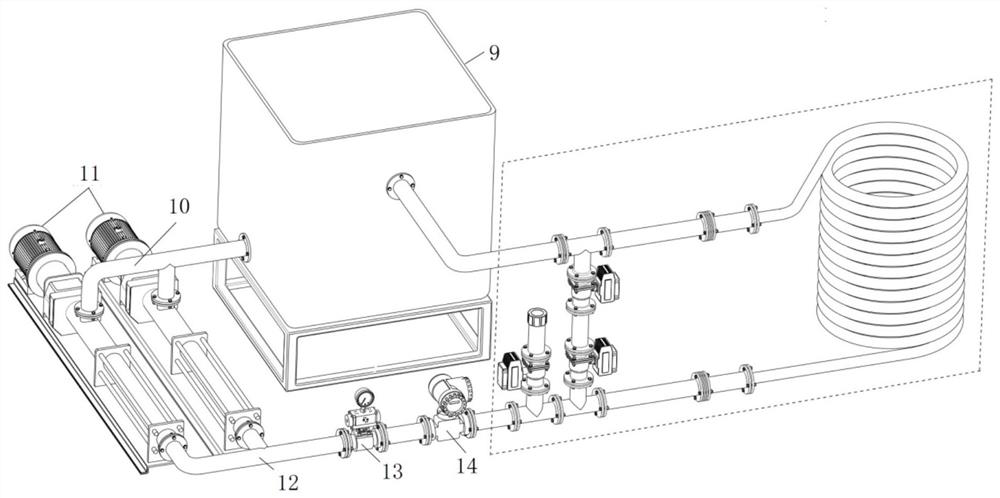

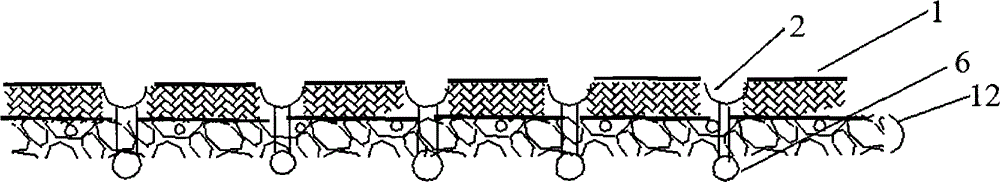

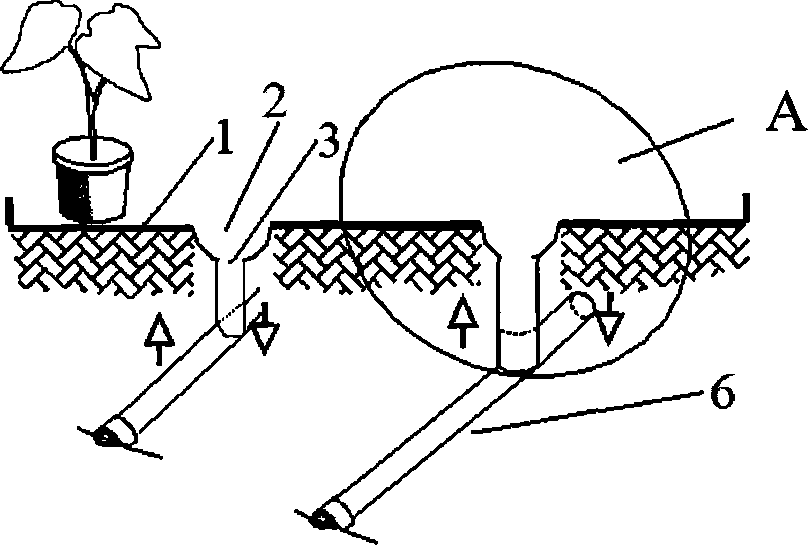

Ground-type tidal Irrigation system

ActiveCN102379235BRealize continuous recyclingEasy to controlClimate change adaptationWatering devicesCold seasonGround temperature

The invention discloses a ground-type tidal Irrigation system, which is used for irrigating potted plants with water or nutrient solution and comprises an upper water supply and drainage trench which is arranged at the upper part of a seedbed, a lower water supply and drainage pipeline which is arranged below the seedbed and is connected with the upper water supply and drainage trench, a water supply system and a water drainage system which are respectively connected with the lower water supply and drainage pipeline and a nutrient solution pond, and a comprehensive control system which are connected with the water supply system, the water drainage system and the nutrient solution pond. An ultraviolet ozone disinfection system and an electric floor heating system are additionally arranged in the system. The ground-type tidal Irrigation system can simulate tide rising and tide falling to irrigate the plants from roots, realizes the continuous cyclic use of the nutrient solution through the ultraviolet ozone disinfection system, reduces the spreading of soil-borne diseases and improves the production benefit of crops; good ground temperature can be provided for the growth and the irrigation of the crops in cold seasons and the situation that the crops grow slowly is avoided; and the comprehensive control system can realize the comprehensive control of the irrigation system, the disinfection system and the electric floor heating system to enable the application to be more convenient and faster.

Owner:BEIJING RES CENT OF INTELLIGENT EQUIP FOR AGRI

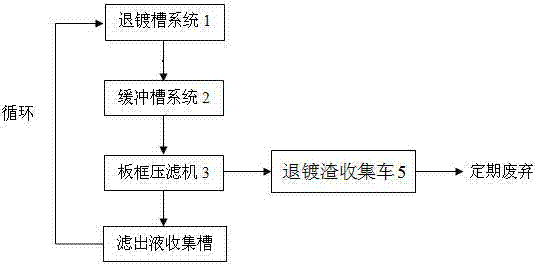

Apparatus and method of plate and frame filter press for hanger stripping production line

The invention which relates to an apparatus and a method of a plate and frame filter press for a hanger stripping production line belongs to the mechanics. The apparatus of the plate and frame filter press for the hanger stripping production line is characterized in that: the apparatus comprises a stripping slot system, a buffer slot system, the plate and frame filter press, a percolate collecting slot, a stripping residue collecting vehicle and a lift platform; the stripping slot system comprises a plurality of stripping slots, and a plurality of stripping liquid lift pumps and stripping liquid lift pipelines which are used for conveying the stripping liquid; and the buffer slot system comprises a buffer slot, a diaphragm pump, and an upper liquidometer of the lift pump, a lower liquidometer of the lift pump, an upper liquidometer of the diaphragm pump and a lower liquidometer of the diaphragm pump which are used for controlling the liquid level. The method of the plate and frame filter press for the hanger stripping production line comprises the following steps: lifting the stripping liquid of a hanger; carrying out liquid level buffering on the stripping liquid of the hanger in the buffer slot; carrying out filter pressing on the stripping liquid in the buffer slot by the plate and frame filter press; and returning a new stripping liquid to the stripping production line to be recycled. According to the invention, the consumption amount of raw materials is saved, the production efficiency is improved, and the production cost is reduced.

Owner:长春富维高新汽车饰件有限公司

Bath solution replenishment and correction method applied to continuous production process of aluminum alloy titanium-zirconium conversion coating

InactiveCN108330479ARealize continuous recyclingEasy to operateLiquid surface applicatorsMetallic material coating processesCorrection methodConversion coating

The invention provides a bath solution replenishment and correction method applied to a continuous production process of an aluminum alloy titanium-zirconium conversion coating. The method comprises the following steps of: cutting aluminum alloy into samples which are 120 mm, 60 mm and 2 mm in size; pretreating the surfaces of the samples; performing conversion treatment on the surfaces of the samples; soaking, stewing and drying the samples in 1L of a titanium-zirconium conversion solution to obtain a conversion coating; taking every twenty treated samples as a batch; after the first batch ofsamples are completely treated in 1L of the titanium-zirconium conversion solution, adding 50 ml of a replenishing liquid A; and in subsequent treatment, adding 50 ml replenishing liquid B into the titanium-zirconium conversion solution after every batch of samples are treated so that the titanium-zirconium conversion solution can be continuously and cyclically used. According to the method, thetitanium-zirconium conversion solution is replenished in time to guarantee that the titanium-zirconium conversion solution can be continuously and cyclically used, and thus continuity of production ismaintained.

Owner:DONGGUAN UNIV OF TECH

A method for absorbing and separating light hydrocarbons from dry gas or industrial tail gas

ActiveCN106474869BLow saturated vapor pressureThe synthesis method is simpleDispersed particle separationAlkaneSolubility

The invention discloses a method for absorbing and separating light hydrocarbon from dry gas or industrial tail gas. The method comprises the following steps: allowing a deep eutectic solvent used as an absorbent to contact with the dry gas or the industrial tail gas, carrying out absorption so as to obtain an absorption solution containing the light hydrocarbon, and subjecting the absorption solution to desorption and separation so as to obtain the light hydrocarbon, wherein the light hydrocarbon mainly contains C2-C4 alkane or olefin. According to the invention, the deep eutectic solvent is used as the absorbent, and an absorption-desorption method is adopted to recycle and separate the light hydrocarbon, wherein the absorbent has significantly high light hydrocarbon solubility and separation selectivity, so highly-efficient separation and recycling of the light hydrocarbon can be realized.

Owner:ZHEJIANG UNIV

A kind of IBC solar cell string light welding device and its welding method

ActiveCN111203661BAvoid displacementImprove yield rateWelding/cutting auxillary devicesAuxillary welding devicesElectrical batteryStringer

The invention discloses an IBC solar battery serial light welding device and a welding method thereof. Compared with the conventional stringer using the last battery piece to fix the position of the metal wire, the IBC battery cannot do this, and needs to use the clamp to cover and fix it. The invention includes a machine frame, a welding ribbon feeding device, a welding ribbon transferring device, a light welding device, a clamp reflow device, a battery conveyor, a clamp conveyor and a pressing positioning fixture. The gripper conveyor is located on one side of the battery conveyor. The ribbon feeder is located below the output of the gripper conveyor. The ribbon transfer device is located above the input of the battery conveyor and the output of the gripper conveyor. Ribbon transfer device, light soldering device, and jig reflow device are arranged in sequence along the conveying direction of the battery conveyor. In the present invention, by pressing the welding ribbon with a pressing and positioning fixture while placing the welding ribbon, the displacement of the welding ribbon during transportation is avoided, and the good product rate of the battery string is greatly improved.

Owner:HANGZHOU COMFIRMWARE TECH CO LTD

A method for absorbing and separating ammonia from ammonia-containing waste gas

ActiveCN106474873BThe synthesis method is simpleRaw materials are easy to getGas treatmentDispersed particle separationSolubilityDesorption

Owner:ZHEJIANG UNIV

Efficient energy-saving injection mold

The invention discloses an efficient energy-saving injection mold. The efficient energy-saving type injection mold comprises a material tank and a shell, the material tank is arranged at one end of the top of the shell, the bottom end of the material tank extends to the middle height position in the shell, and a partition plate is vertically welded to the position, on one side of the material tank, in the shell. A feeding chamber is formed in the side, close to the material tank, of the partition plate in the shell, and an injection molding chamber is formed in the side, away from the feeding chamber, of the partition plate in the shell. According to the efficient energy-saving injection mold, a pair of piston cylinders for containing molten materials in a reciprocating manner is symmetrically connected to a main material conveying pipe, and a set of fixed mold and movable mold for injection molding are arranged in the shell and a connecting box, so that the fixed mold and the movable mold at the shell and the connecting box can be used for alternately and intermittently machining and producing plastic parts; and the main material conveying pipe can continuously convey the materials, continuous feeding of the main conveying pipe cannot block a pipeline, the injection molding efficiency is improved, the volume of the materials needing to be injected in each time of injection molding production is easier to control, and the product quality is higher.

Owner:傅剑雄

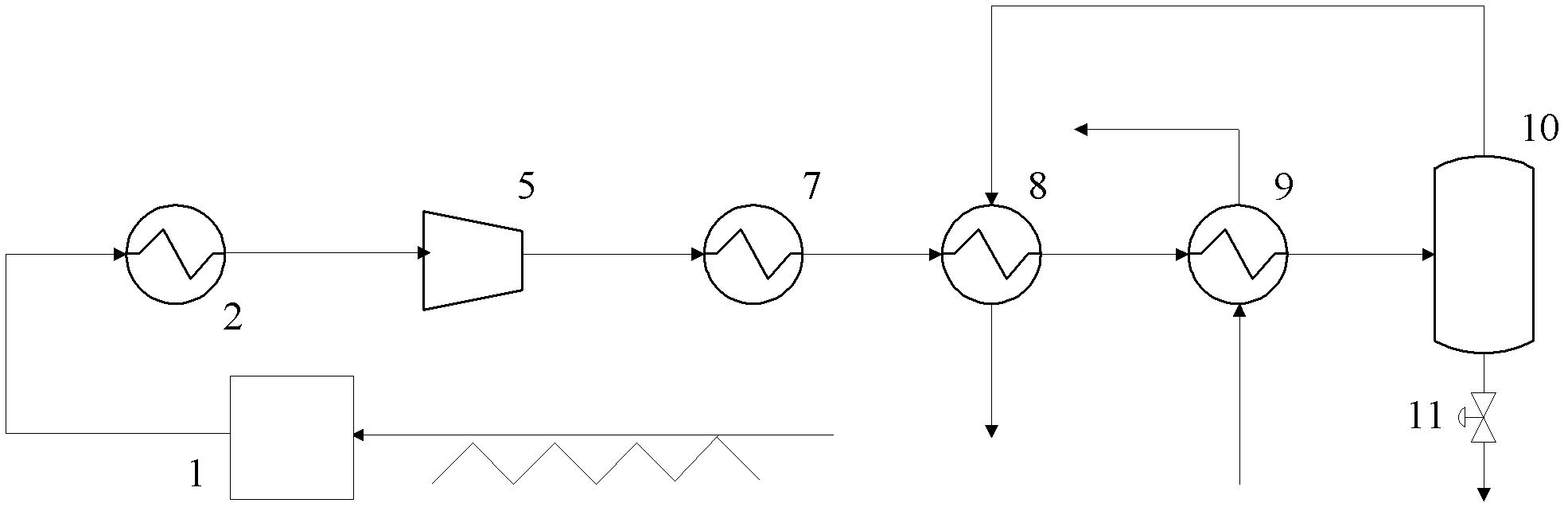

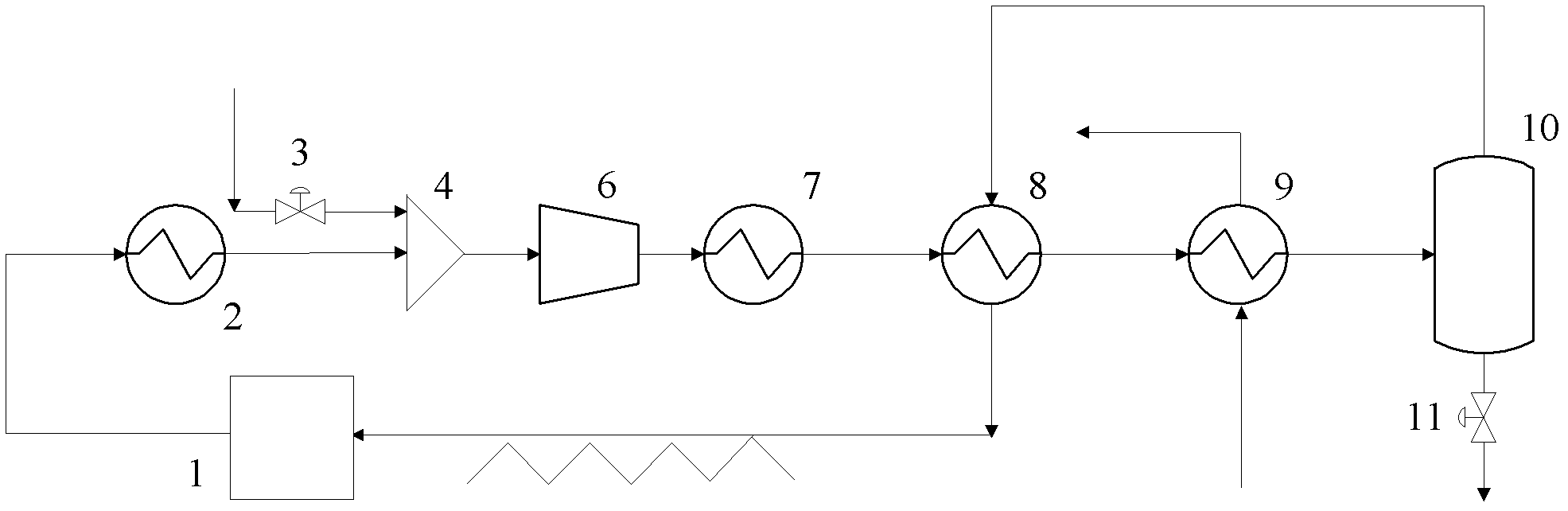

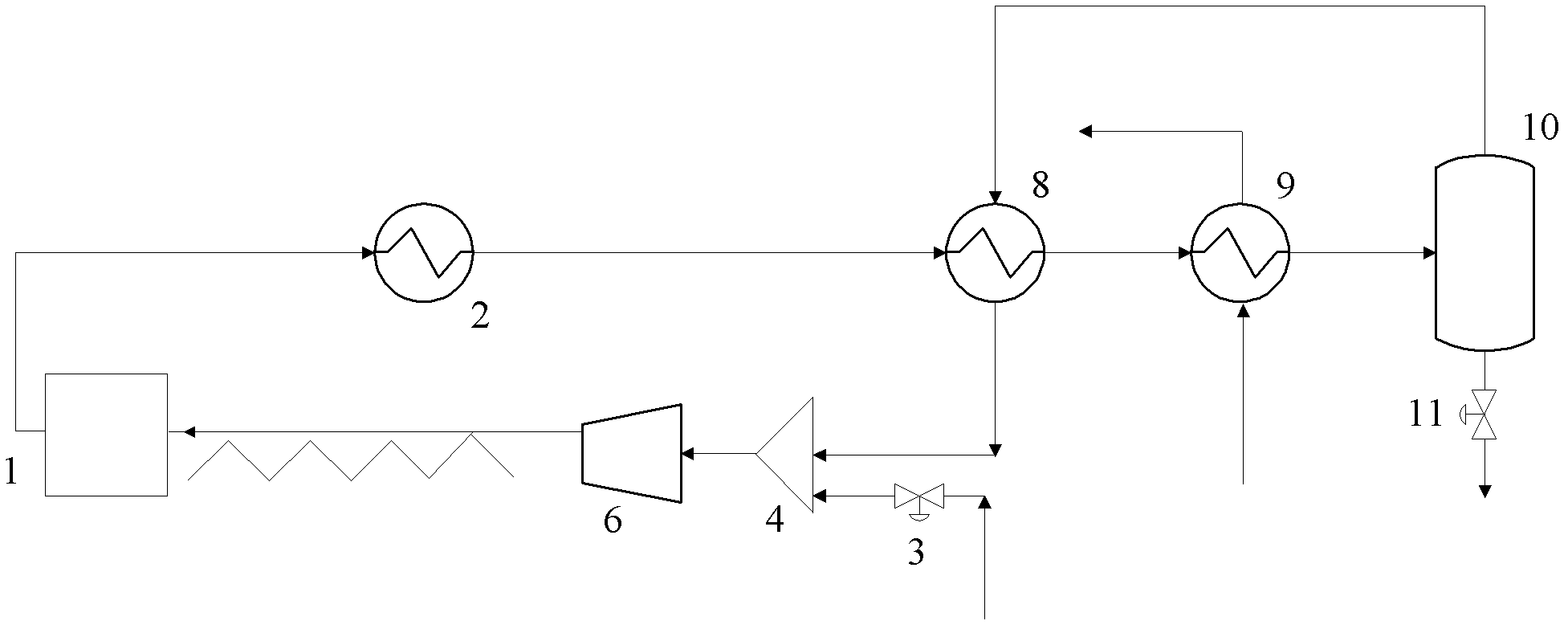

Process and device for recycling organic waste gas by refrigeration mode

InactiveCN102494516AHigh recovery rateGuaranteed recyclingSolidificationLiquefactionPolystyreneFlash evaporation

The invention relates to a process and device for recycling organic waste gas by a refrigeration mode, wherein the process and device can be used for water gas recycling in the production process of a polystyrene board in the printing industry. The device comprises a drying device, a heat exchanger, a gas conveying device, a refrigeration device and a separation tank, wherein silk screens are installed on the upper part of the separation tank; the gas conveying device is positioned between a first water cooler and a second water cooler or is positioned between the first heat exchanger and a polystyrene production line; after high-temperature waste gas is subjected to water cooling and low-temperature refrigeration, organic matters are cooled down; at the temperature of minus 60-20DEG C and under the pressure of 0-5MPa, after flash evaporation and gas and liquid separation, waste gas containing less organic matters exchanges heat with the deep-cool waste gas; after cold quantity is recycled, the waste gas is introduced to the polystyrene production line to be used as the sweep gas for recycling or discharged directly; when the treated waste gas is used as the sweep gas for recycling, the organic solvent recovery rate is greater than 99.5%; and when the treated waste gas is discharged directly, the organic solvent recovery rate is greater than 85%. According to the invention, the process and device have the advantages that process is simple, operation is convenient, recovery rate of organic waste gas is high and the like, and continuous recovery can be realized.

Owner:QINGDAO UNIV OF SCI & TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com