Circulating oil supply system and internal circle slicer system with the same

A circulating oil supply and oil supply technology is applied in the direction of manufacturing tools, metal processing machinery parts, maintenance and safety accessories, etc. It can solve the problems of inability to realize continuous circulation of cutting oil, low degree of automation, and blockage of oil mist treatment devices. Achieve the effect of reducing equipment cost and labor cost and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] This embodiment provides a circulating oil supply system, such as Figure 1-4 As shown, it includes a cutting oil recovery device, a purification device and an oil supply device that communicate with the cutter head installation space in sequence to form a first circulating oil supply circuit, and communicate with the above cutter head installation space in sequence to form a second circulating oil supply circuit. Oil mist treatment device, purification device and oil supply device, the above-mentioned first circulating oil supply circuit is used to recover and purify the cutting oil in the cutterhead installation space and supply oil to the cutterhead installation space, and the above-mentioned second circulating oil supply circuit is used to Recover, condense and purify the oil mist in the cutter head installation space and supply oil to the cutter head installation space. The above settings make the supply, recovery and oil mist treatment of the cutting oil organical...

Embodiment 2

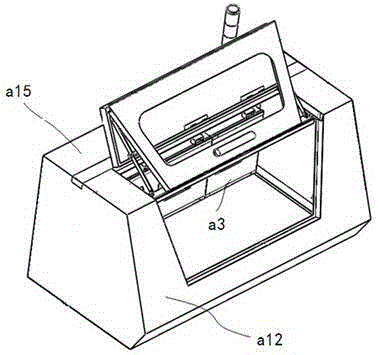

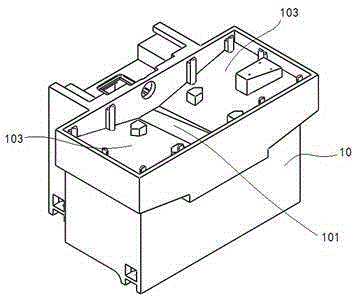

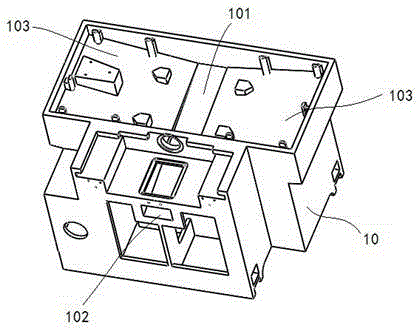

[0080] This embodiment provides a circulating oil supply system, which is an improvement on the basis of Embodiment 1, specifically an improvement on the cutting oil recovery device, such as Figure 10-15 As shown, at least one protective cover a3 with a containing space is arranged inside the machine cover a1, and the protective cover a3 accommodates the cutter head through the above-mentioned containing space; the bottom of the protective cover a3 is provided with a drain port a33.

[0081] Such as Figure 12-15 As shown, the protective cover a3 is a square box surrounded by the front panel a31, the rear panel a32, the upper panel a34, the lower panel a35, the left panel a36 and the right panel a37; A rear installation port a321 corresponding to the installation port a2 on the hood a1 is opened on the panel a32, and the headstock with the cutter head passes through the installation port a2 and the rear installation port a321; the drain port a33 is opened in the On the lower p...

Embodiment 3

[0093] This embodiment provides an internal circle slicer system, including several internal circle slicers 08, and an oil supply system for supplying oil to the above-mentioned several internal circle slicers 08, wherein the oil supply system is the above-mentioned embodiment 2 or embodiment The circulating oil supply system described in 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com