Process and device for recycling organic waste gas by refrigeration mode

A technology of organic waste gas and waste gas, applied in refrigeration and liquefaction, solidification, lighting and heating equipment, etc., can solve the problems of environmental hazards, high operating costs, high operating costs, protect the ecological environment, reduce economic losses, and achieve continuous recovery. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

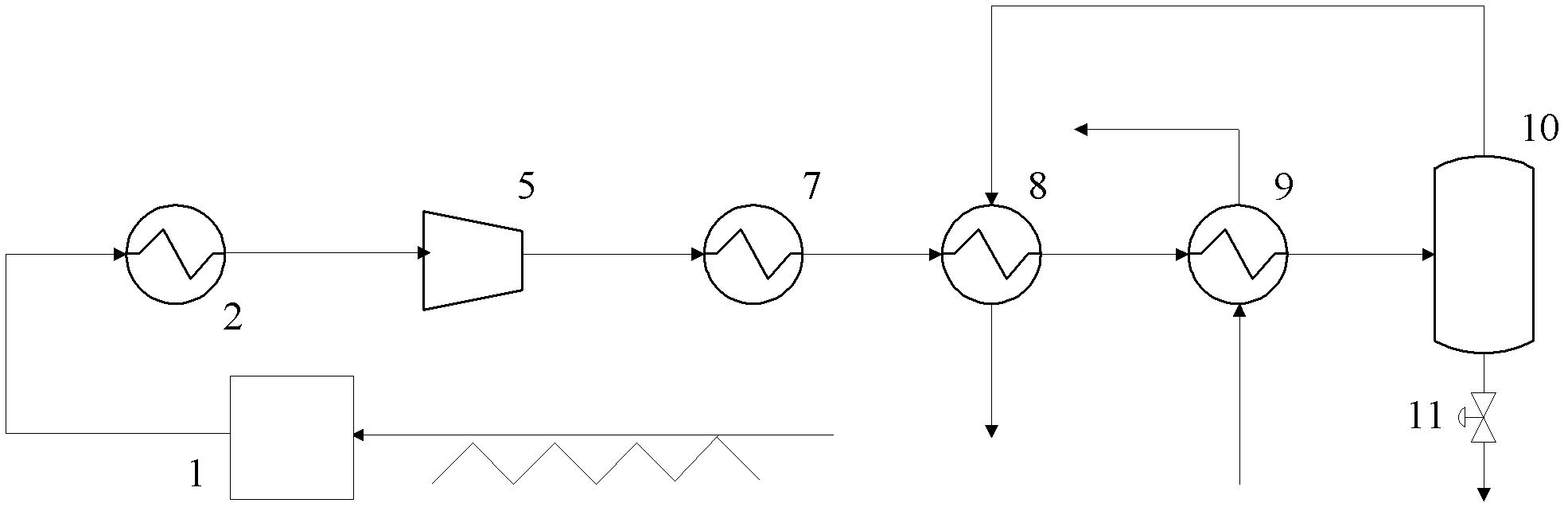

[0020] Such as figure 1 As shown, the organic waste gas recovery process of the present invention and related devices include a drier 1, a first water cooler 2, a compressor 5, a second water cooler 7, a first heat exchanger 8, a second heat exchanger 9, a separation Tank 10 and level control valve 11. The exhaust gas outlet of the PS board production line is connected to the inlet of the dryer 1, the outlet of the dryer 1 is connected to the inlet of the first water cooler 2, the first water cooler 2 cools the high-temperature exhaust gas to room temperature, and the outlet of the first water cooler 2 is connected to the compressor 5 inlet is connected to boost the pressure of exhaust gas; the outlet of compressor 5 is connected to the inlet of the tube side of the second water cooler 7, and the exhaust gas is cooled again; the outlet of the tube side of the second water cooler 7 is connected to the shell side of the first heat exchanger 8, here In the heat exchanger, the e...

Embodiment 2

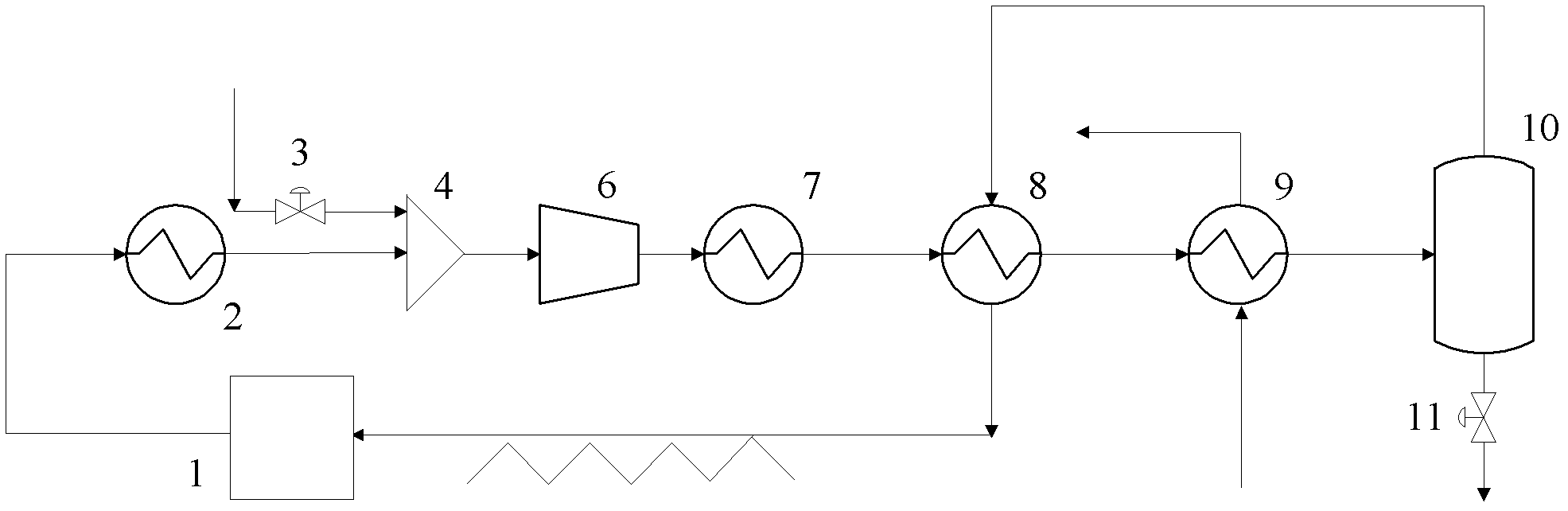

[0024] Such as figure 2As shown, the organic waste gas recovery process and related devices of the present invention include a drier 1, a first water cooler 2, an automatic control valve 3, a mixer 4, a fan 6, a second water cooler 7, a first heat exchanger 8, and a second water cooler 8. Two heat exchangers 9, a separation tank 10 and a liquid level control valve 11. The outlet of the dryer 1 is connected to the inlet of the tube side of the first water cooler 2, the first water cooler 2 cools the high-temperature exhaust gas to room temperature, the outlet of the tube side of the first water cooler 2 is connected to the inlet of the mixer 4, and the outlet of the mixer 4 is connected to the inlet of the fan 6 Connect to boost the pressure of the exhaust gas; the outlet of the fan 6 is connected to the inlet of the second water cooler 7, and the exhaust gas is cooled again; the outlet of the second water cooler 7 is connected to the shell side of the first heat exchanger 8, ...

Embodiment 3

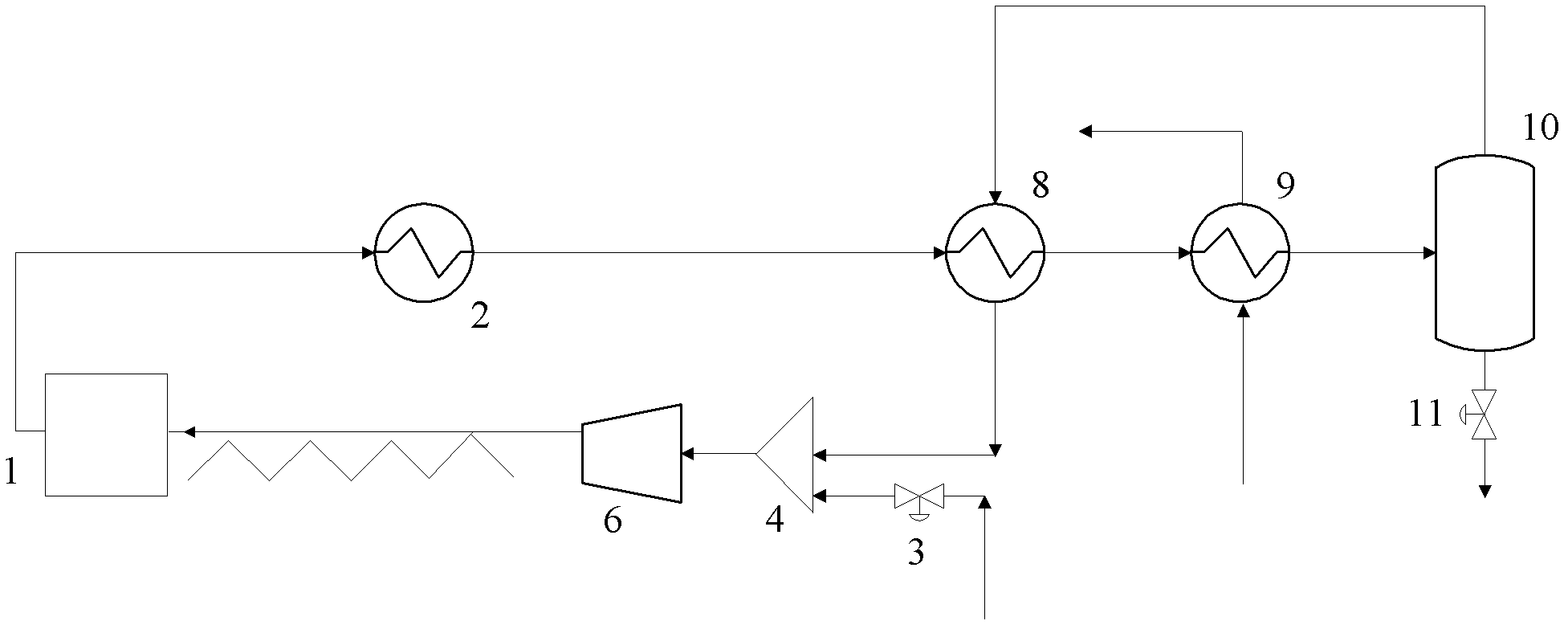

[0028] Such as image 3 As shown, the organic waste gas recovery process and related devices of the present invention include a dryer 1, a first water cooler 2, an automatic control valve 3, a mixer 4, a fan 6, a first heat exchanger 8, and a second heat exchanger 9, Separation tank 10 and liquid level control valve 11. The outlet of dryer 1 is connected to the inlet of the tube side of the first water cooler 2, the first water cooler 2 cools the high-temperature exhaust gas, the outlet of the tube side of the first water cooler 2 is connected to the shell side of the first heat exchanger 8; the first heat exchanger 8 The outlet on the right side of the shell side is connected to the inlet on the left side of the shell side of the second heat exchanger 9; the refrigerant of the ice machine refrigeration equipment enters the lower inlet of the shell side of the second heat exchanger 9, and the refrigerant exchanges heat with the exhaust gas and is transferred by the second heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com