Application of hydrogen-donor solvent and surfactant in methanation reaction

A technology for surfactants and hydrogen-donating solvents, applied in the application field of hydrogen-donating solvents and surfactants in methanation reactions, can solve problems such as easy agglomeration, poor activity, and fewer active sites, and achieve stable system thermal balance , mild reaction conditions, increased stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

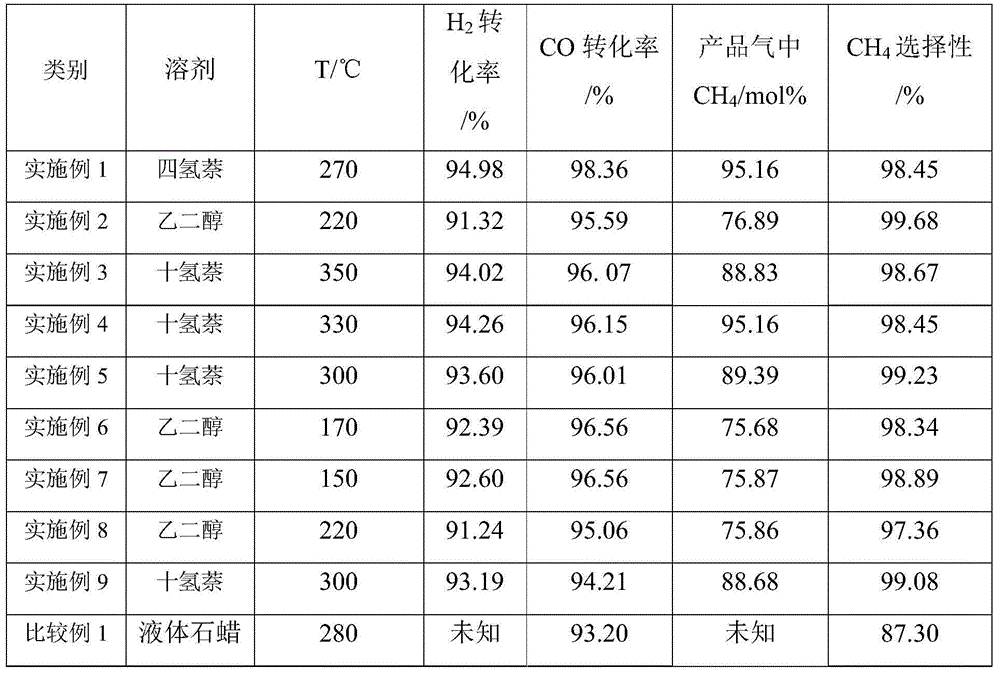

Examples

Embodiment 1

[0031] Weigh 58.16g Ni(NO 3 ) 2 ·6H 2O (0.2mol), dissolve it in 570ml of ethylene glycol solution, then add 2.35g of PVP, after the dissolution is complete, put the beaker in a 60°C water bath. Under stirring conditions, 300.35 g of hydrazine hydrate was added dropwise with a microsampler. After mixing evenly, add 1mol / L NaOH solution to adjust the pH to about 12. Afterwards, the temperature was raised to 70° C. for 3.5 hours. After the reaction was complete, a black solid precipitate was obtained after centrifugation and removal of the supernatant. The black solid precipitate was washed successively with ethanol and distilled water, centrifuged, and dried under nitrogen protection to obtain a black powder. Then the saturated ammonium molybdate solution is impregnated on the black powder according to the molar ratio of Mo (molybdenum): Ni is 10:100, and the impregnation time is 19h. Afterwards, the impregnated sample was fired for 2 h at 270 °C in an Ar atmosphere; then t...

Embodiment 2

[0034] Weigh 58.16g Ni(NO 3 ) 2 ·6H 2 O (0.2mol), dissolve it in 650ml of ethylene glycol solution, then add 2.30g of PVP, after the dissolution is complete, put the beaker in a 60°C water bath. Under stirring conditions, 300.35 g of hydrazine hydrate was added dropwise with a microsampler. After mixing evenly, add 1mol / L NaOH solution to adjust the pH to about 10. Afterwards, the temperature was raised to 70° C. for 2.5 hours. After the reaction was complete, a black solid precipitate was obtained after centrifugation and removal of the supernatant. The black solid precipitate was washed successively with ethanol and distilled water, centrifuged, and dried under nitrogen protection to obtain a black powder. Then the saturated ammonium molybdate solution is impregnated on the black powder according to the molar ratio of Mo (molybdenum): Ni is 4:100, and the impregnation time is 17h. Afterwards, the impregnated sample was fired for 3 h at 330 °C in an Ar atmosphere; then t...

Embodiment 3

[0037] Weigh 58.16g Ni(NO 3 ) 2 ·6H 2 O (0.2mol), dissolve it in 1200ml ethylene glycol solution, then add 1.55g PVP, after the dissolution is complete, put the beaker in a 60°C water bath. Under stirring conditions, 200.23 g of hydrazine hydrate was added dropwise with a microsampler. After mixing evenly, add 1mol / L NaOH solution to adjust the pH to about 12. Afterwards, the temperature was raised to 65° C. for 3 h. After the reaction was complete, the black solid precipitate was obtained after centrifugation and removal of the supernatant. The black solid precipitate was washed successively with ethanol and distilled water, centrifuged, and dried under nitrogen protection to obtain a black powder. Then impregnate the saturated ammonium molybdate solution on the black powder according to the molar ratio of Mo (molybdenum): Ni: 15:100, and the impregnation time is 24h. Afterwards, the impregnated sample was calcined at 320 °C in an Ar atmosphere for 2 h; then the temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com