Separating preparation method of acetylene by absorbing pyrolysis gas with ionic liquid

An ionic liquid and pyrolysis gas technology, applied in absorption purification/separation, bulk chemical production, organic chemistry, etc., can solve the problems of difficult long-term recycling, high requirements for pyrolysis gas composition, inactivation, etc., and achieve solvent consumption. The effect of less, low saturated vapor pressure and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

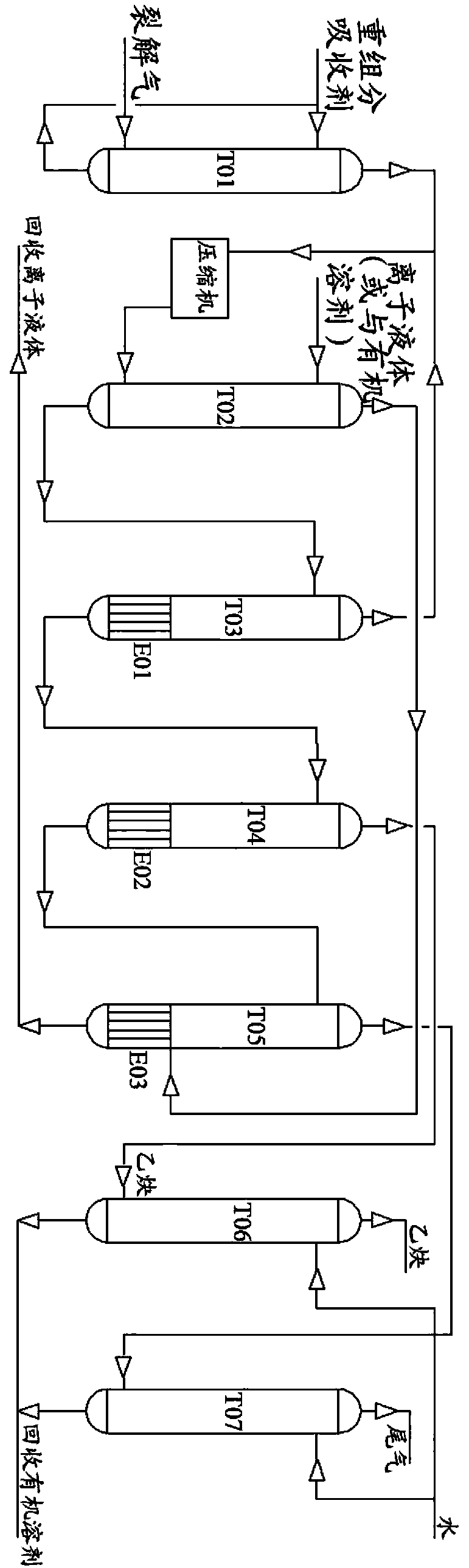

[0041] like figure 1 Shown, the present invention adopts ionic liquid absorption to separate the method for preparing acetylene from cracking gas, comprising:

[0042] (1) The cracked gas that has been cooled and dehydrated passes through the heavy component absorption tower T01 from bottom to top, and is countercurrently contacted with the heavy component absorbent added at the top of the tower. All tar, benzene, naphthalene and other heavy components with a boiling point of 80 ℃ ~ 300 ℃ and some high alkynes are absorbed to prevent the heavy components from coking and affecting the operation of the compressor. The heavy component absorption liquid obtained from the bottom of the heavy component absorption tower T01 can be re-added from the top of the heavy component absorption tower T01 for recycling, and can be recovered by rectification after saturation; or, the heavy component absorption liquid can be desorbed by heating and air stripping under ambient pressure , separat...

Embodiment 2

[0049] The pyrolysis gas produced by plasma pyrolysis of coal is used after dedusting, and the composition contains 13% (molar concentration, the same below) C 2 h 2 , 0.2%CH 4 , 0.9%C 2 h 4 , 9.5%CO, 0.8%N 2 , 73%H 2 , 1.0% homoyne and other small amounts of components above C3, the cracking gas flow rate is 1500Nm 3 / h.

[0050] like figure 1 And Example 1, N-methylpyrrolidone is used as the absorbent for heavy component absorption, and it is countercurrently contacted and absorbed with the cracked gas at 35°C and 0.1 MPa. The remaining cracked gas is pressurized to 0.65 MPa through a compressor, and cooled to At 30°C, a mixed solution of 98% (volume percentage) [Bmim][OAc] (1-butyl-3-methylimidazole acetate) and 2% (volume percentage) N-methylpyrrolidone (NMP) is Absorbent, the absorption liquid is heated to 80°C through the reboiler E01, desorbs the light component under decompression to 0.25MPa, then heats up to 110°C through the reboiler E02, desorbs under the de...

Embodiment 3

[0052] Cracked gas produced by cracking natural gas with high-frequency plasma, the composition is 11% (molar concentration, the same below) C 2 h 2 , 5.2%CH 4 , 0.4%C 2 h 4 , 8.2%CO, 72%H 2 , 1.8% homoyne and a small amount of other components, cracking gas flow 2200Nm 3 / h.

[0053] like figure 1 As in Example 1, N-methylpyrrolidone was used as the absorbent for the absorption of heavy components, and it was contacted and absorbed with cracked gas countercurrently at 35° C. and 0.1 MPa. The remaining cracked gas is compressed to 1.0MPa, cooled to 20°C, and the absorbent is ionic liquid [Bmim][MeHPO 3 ] (1-butyl-3-methylimidazobutyl phosphate), no organic solvent is added, the absorption liquid is heated to 80°C through the reboiler E01, decompressed to 0.25MPa to desorb the light components, and then passed through the reboiler E01 to desorb the light components Boiler E02 is heated to 110°C, decompressed to 0.1MPa and desorbed to obtain the acetylene component. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com