Material supporting mechanism and laser pipe cutting machine provided with same

A technology of pipe cutting machine and material support, which is applied to laser welding equipment, tubular objects, welding/cutting auxiliary equipment, etc. The effect of sagging and cost control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

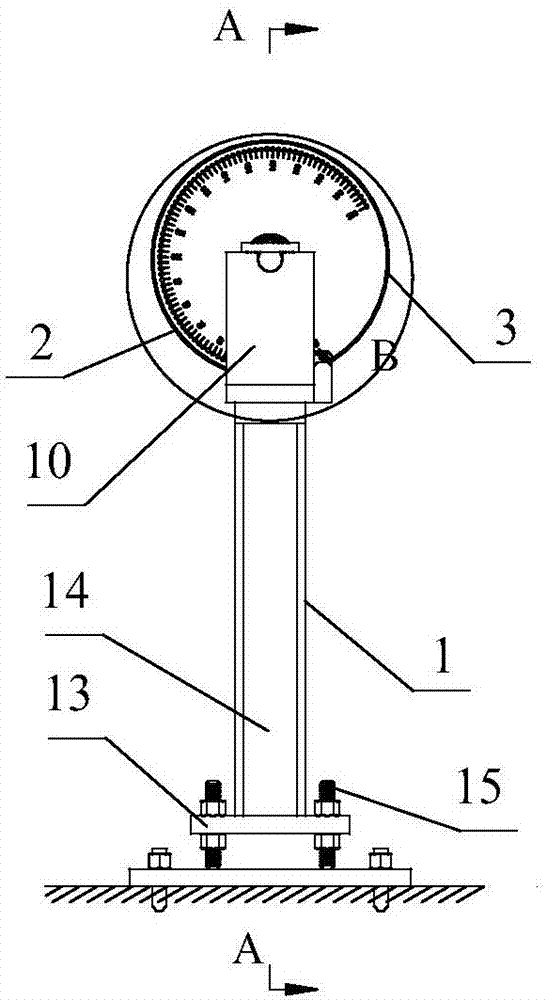

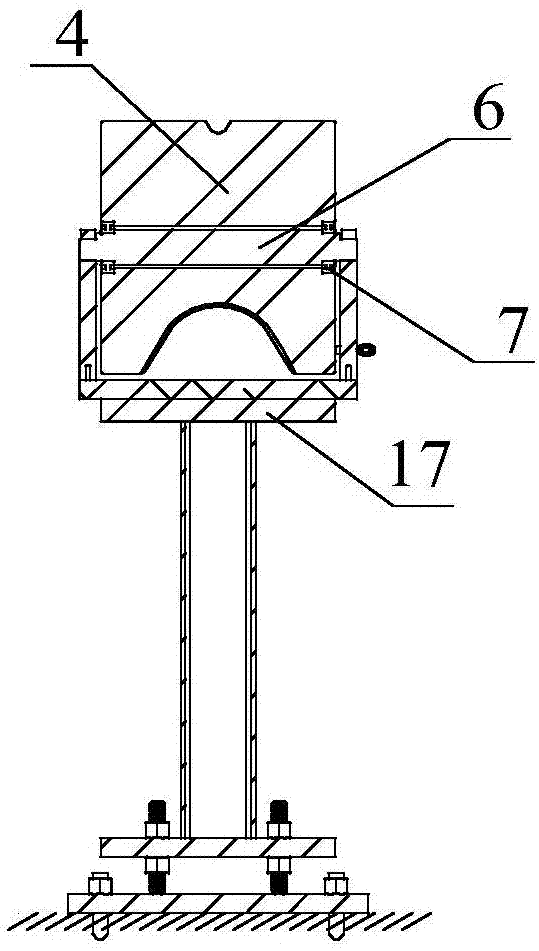

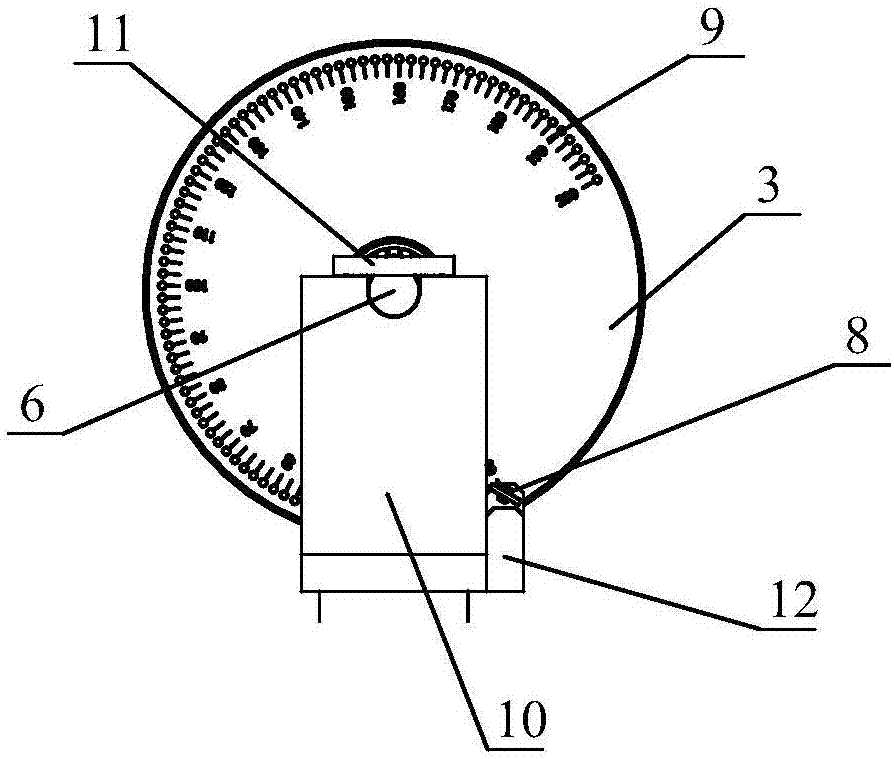

[0021] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0022] see figure 1 As shown, the embodiment of the present invention provides a support mechanism, including a support mechanism 1, a support mechanism 2 is provided on the top of the support mechanism 1, and the support mechanism 2 includes a variable diameter wheel 3. In this embodiment, the variable diameter wheel 3 The variable diameter range is 20mm ~ 200mm. In actual situations, it can be rotated according to the needs. The top of the variable diameter wheel 3 is the supporting channel 4, and the supporting channel 4 is used to place the pipe 5 to be cut. The variable diameter wheel 3 is opposite to the A reducing wheel shaft 6 is arranged between the two sides of the reducing wheel shaft 6, and the two ends of the reducing wheel shaft 6 are detachably connected with the outside of the reducing wheel 3 through a jumper spring 7; A diame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com