Quick-drying type pad printing machine

A pad printing machine and quick-drying technology, applied to printing machines, rotary printing machines, general parts of printing machinery, etc., can solve problems such as untimely drying of ink, damage to ink clarity, stretching and distortion of graphics, etc., to achieve Improve production efficiency and product quality, improve printing quality, and reduce the effect of defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

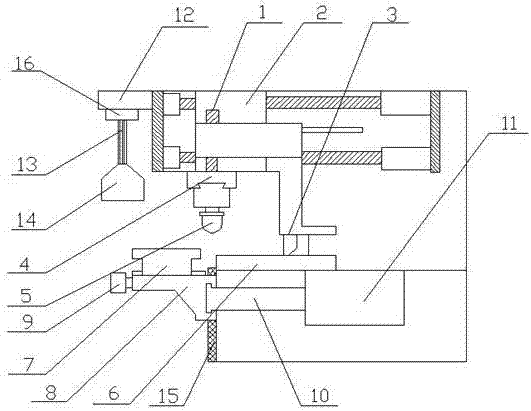

[0021] The present invention will be further elaborated and described below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer ” refer to directions towards or away from the geometric center of a particular part, respectively.

[0022] The quick-drying pad printing machine as shown in the figure includes a movable shaft 1, a casing 2, a scraper 3, a silicone head 5, an ink tray 6, a workbench 7 and a handle 9, and the movable shaft 1 is placed on the upper end of the casing 2 , and connect the silicone head 5 through the silicone head base 4, the silicone head 5 is placed above the ink t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com