Novel stone powder film bag pile mixed grouting material and mixing construction method

A technology of grouting materials and stone powder, which is applied in infrastructure engineering, soil protection, construction, etc., can solve the problems of direct discharge of stone powder, environmental pollution, etc., and achieve the effect of satisfying the coring strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

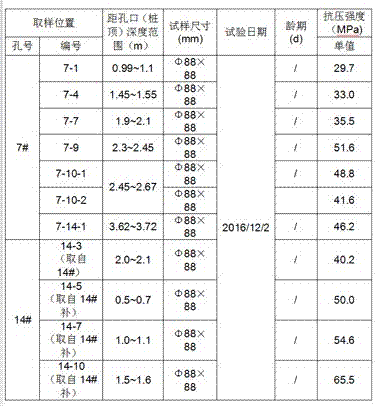

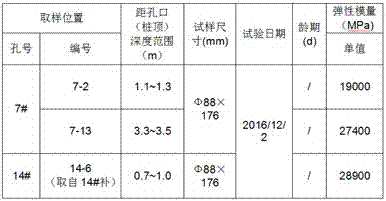

Examples

Embodiment 1

[0016] A new type of mixed grouting material for stone powder film bag piles, the composition of which includes: cement, stone powder, additives, fly ash, and mineral powder, characterized in that the weight fraction of the stone powder film bag pile mixed grouting material is: 1 part of cement , 1-3 parts of stone powder, 0-0.15 parts of fly ash, and 0.1-0.3 parts of additives.

Embodiment 2

[0018] According to the novel stone powder film bag pile mixed grouting material described in Example 1, the weight fraction of the stone powder film bag pile mixed grouting material is: 1 part of cement, 1 part of stone powder, and 0.2 part of additive.

Embodiment 3

[0020] According to the novel stone powder film bag pile mixed grouting material described in embodiment 1 or 2, the weight fraction of the stone powder film bag pile mixed grouting material is: 1 part of cement, 2 parts of stone powder, 0.15 part of fly ash, and 0.1 part of additive .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com