A method for electrodepositing nanocrystalline functional coatings on the surface of anodized porous metal substrates

A technology of anodic oxidation and porous metal, which is applied in the direction of anodic oxidation, metal material coating process, liquid chemical plating, etc. It can solve the problems of high chemical activity of titanium metal, difficulty in ensuring interfacial bonding force, and difficulty in growing functional coatings, etc. , to achieve good interfacial bonding, relieve growth stress, and avoid cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

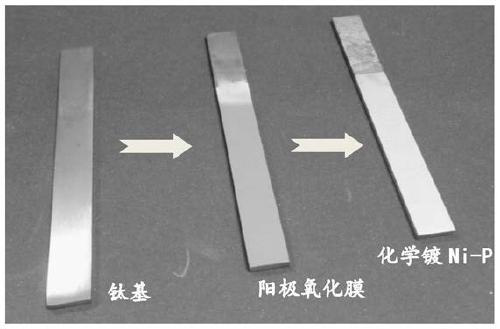

[0033] In this embodiment, the TA2 high-purity titanium sheet is used as the base material, and the commercially rolled and annealed high-purity titanium is cut into flake-shaped titanium as the substrate, and the size is 5mm×2mm×0.5mm.

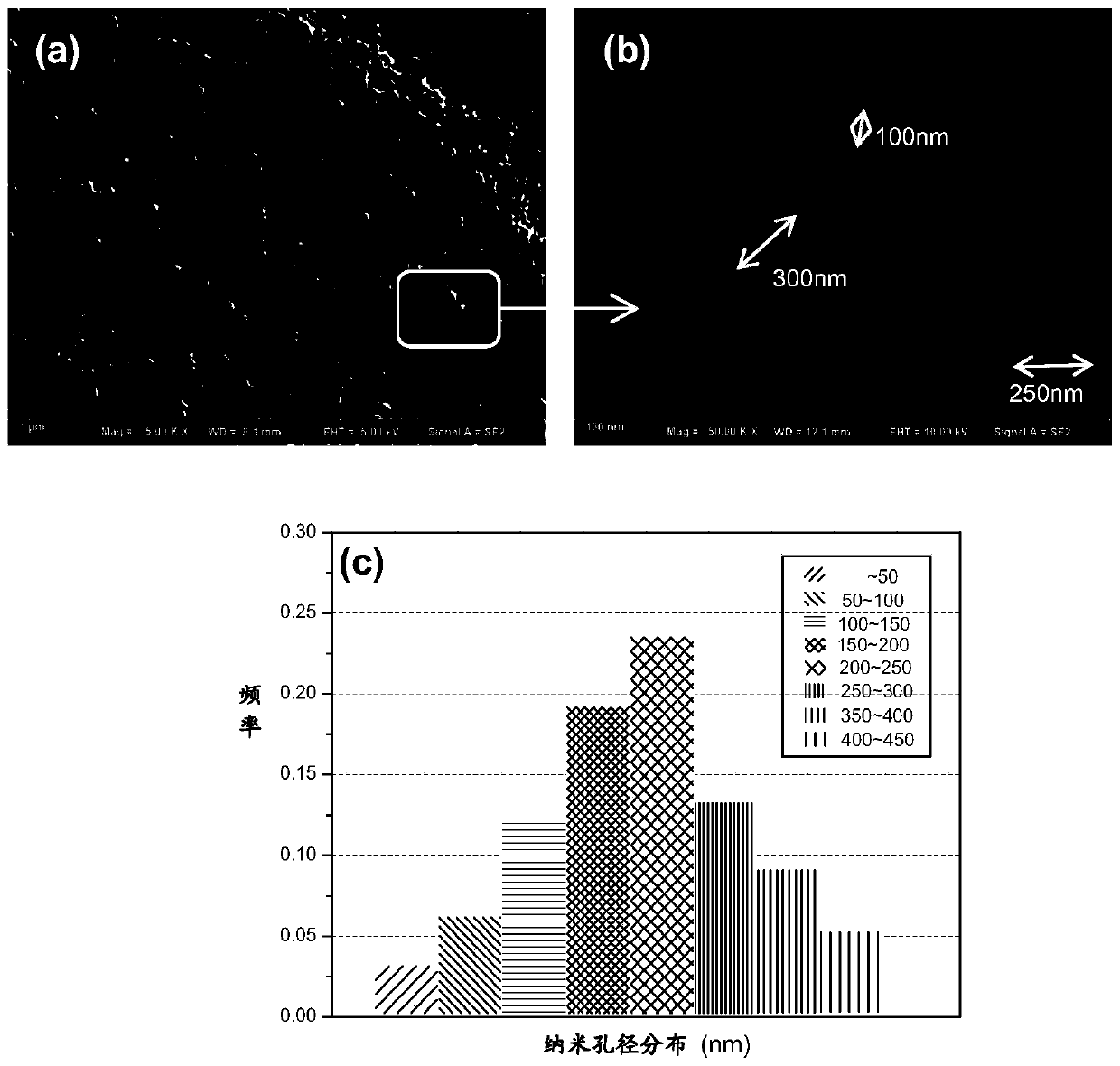

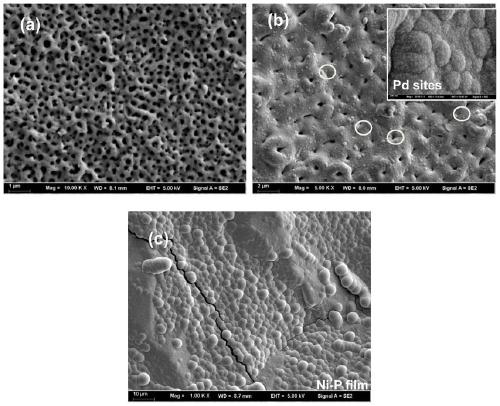

[0034] The method of electro-depositing nanocrystalline functional coatings on the surface of anodized porous metal substrates includes sequentially performing mechanical polishing on the surface of high-purity titanium substrates, degreasing with hot lye, anodizing, Pd 2+ -Sn 2+ Sensitization activation, Ni-P electroless plating and pulse electrodeposition nanocrystalline functional coating.

[0035] The concrete steps of described method are as follows:

[0036] The first step, mechanical polishing: use 800 # , 1200 # and 1500 # The SiC water sandpaper is used for rough grinding of the pure titanium substrate, and then Al 2 o 3 After polishing with polishing paste, after forming a mirror surface, observe the surface with a metallograp...

Embodiment 2

[0055] The difference from Example 1 is that the aging annealing treatment is performed before the pulse electrodeposited nanocrystalline functional coating, the treatment temperature is 450° C., the time is 1.5 h, and the furnace is air-cooled.

[0056] Compared with Example 1, the difference is that: 450°C×2.5h aging annealing treatment is carried out on the Ni-P electroless plating including the anodized film, its main function is to reduce the growth stress of the electroless Ni-P alloy and reduce the thickness of the coating. Cracking tendency; the dispersed phases such as Ni3P generated at the same time diffuse with Ti / TiO2 atoms in the titanium-based nanopores, which can promote the metallurgical combination of the interface.

[0057] The method is used to prepare a large-thickness (controllable) nanocrystalline functional coating on the surface of the anodic oxide film, which has a compact structure and excellent performance. The interface between the surface coating an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com