Method of preparing nano silicon line without metal catalyst under low temperature

A metal and catalyst-free technology, applied in chemical instruments and methods, inorganic chemistry, nanotechnology, etc., can solve the problems of not reflecting the real performance of silicon nanowires, unsuitable for industrial production applications, and increasing the production cost of nanosilicon wires. Achieve the effect of industrialized preparation, low cost and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

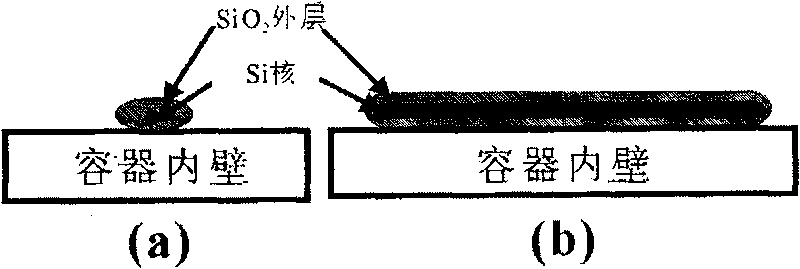

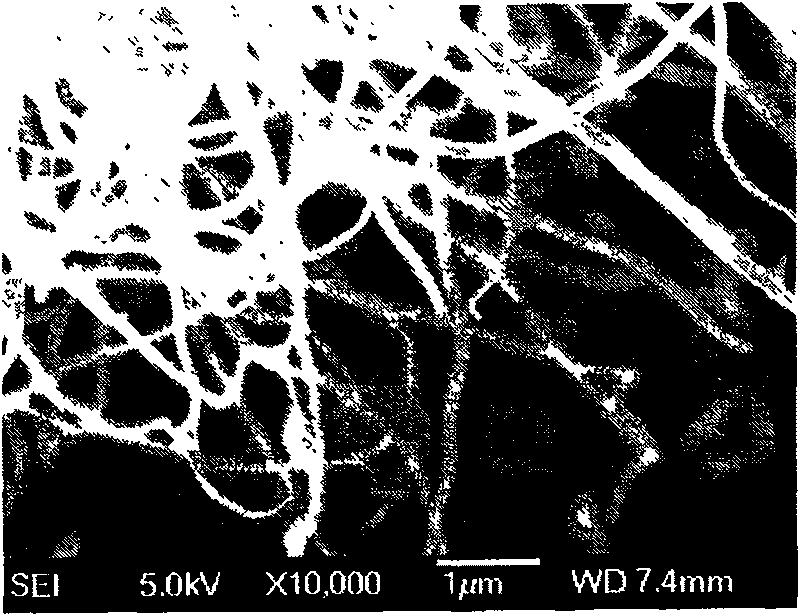

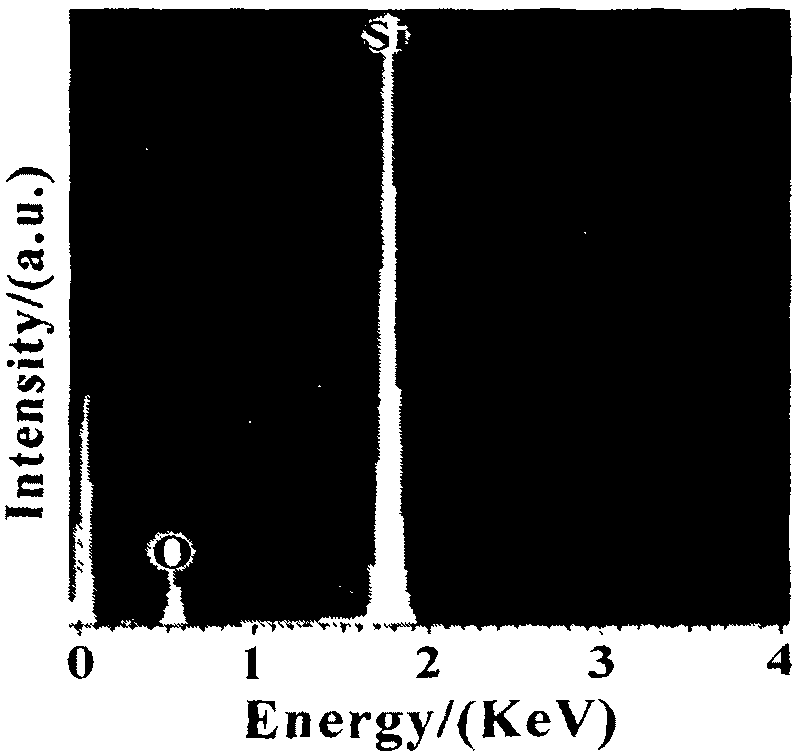

[0027] Example 1: Mix 1% of the total amount of silica sol with silicon tetrachloride and place it in a sealed reactor. The total amount of raw materials accounts for 5% of the reactor container. Temperature and 1MPa pressure were kept for 1 hour, and nanometer silicon wires with an average diameter of about 200nm and an average length of about tens of microns were prepared.

Embodiment 2

[0028] Example 2: Mix silica sol and silicon tetrachloride accounting for 5% of the total amount and place it in a sealed reactor. The total amount of raw materials accounts for 5% of the reactor container. Temperature and pressure of 1 MPa were kept for 12 hours, and nano silicon wires with an average diameter of about 200 nm and an average length of about tens of microns were prepared.

Embodiment 3

[0029] Example 3, after mixing 5% of the total amount of silica sol and silicon tetrachloride, place it in a sealed reactor. The total amount of raw materials accounts for 8% of the reactor container. Temperature and 4MPa pressure were kept for 1 hour, and nano silicon wires with an average diameter of about 180 nm and an average length of about tens of microns were prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com