Device and method for dynamic growth of large-scale perovskite single crystal

A technology of growth device and growth method, applied in the field of dynamic growth device of large-size perovskite single crystal, can solve problems such as affecting the application of perovskite materials, weak research on single crystal materials, and difficulty in obtaining perovskite crystals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 relates to the growth of large-scale methylamine lead bromide crystal, comprises the steps:

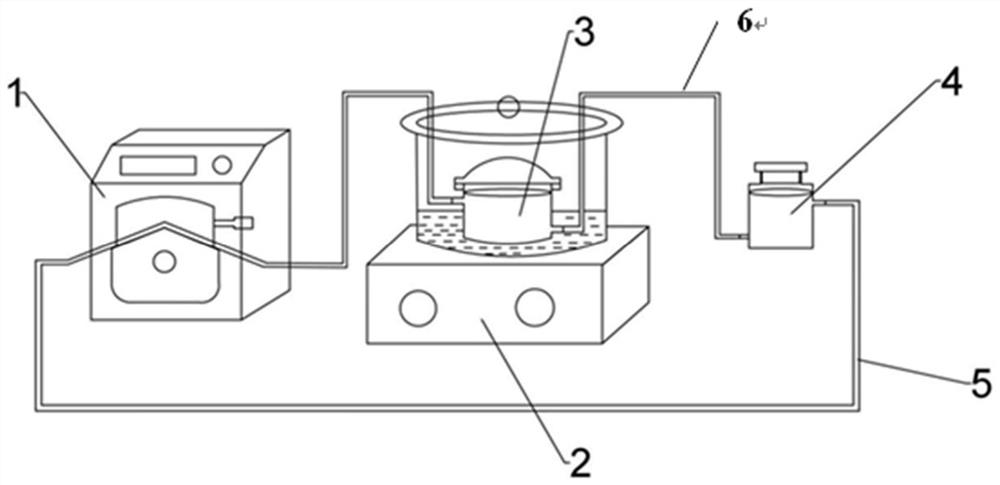

[0031] Step a: Pretreatment of the growth device: cleaning and drying the crystal growth cavity and the raw material supply cavity; connecting the upper solution outlet of the crystal growth cavity 3 with the upper solution outlet of the raw material supply cavity 4 through the first section of silica gel tube 5 , and connect the lower solution outlet of the crystal growth chamber 3 with the lower solution outlet of the raw material supply chamber 4 through the second section of silicone tube 6 .

[0032] Step b: preparing methylamine bromide, and further preparing methylamine lead bromide solution.

[0033] In an ice-water bath, mix methylamine-ethanol solution and hydrobromic acid at a molar ratio of 1:1.2 and stir for 2 hours, then evaporate at 60°C under low vacuum, wash and recrystallize three times with ethanol and ether, put it in a fume hood to air-dry, and...

Embodiment 2

[0041] Example 2 is also the growth of large-sized methylammonium lead bromide crystals. The difference from Example 1 is that in step f, the crystal growth temperature is 70°C, and the flow rate of the peristaltic pump is 30ml / min.

Embodiment 3

[0043] Embodiment 3 relates to the growth of large-scale methylammonium iodide lead crystal, comprises the steps:

[0044] Step a: Pretreatment of the growth device: cleaning and drying the crystal growth cavity and the raw material supply cavity; connecting the upper solution outlet of the crystal growth cavity 3 with the upper solution outlet of the raw material supply cavity 4 through the first section of silica gel tube 5 , and connect the lower solution outlet of the crystal growth chamber 3 with the lower solution outlet of the raw material supply chamber 4 through the second section of silicone tube 6 .

[0045] Step b: preparing methylamine iodide, and further preparing methylamine iodide lead solution.

[0046] In an ice-water bath, mix methylamine-ethanol solution and hydroiodic acid at a molar ratio of 1:1.2 and stir for 2 hours, then evaporate at 60°C under low vacuum, wash and recrystallize three times with ethanol and ether, put it in a fume hood to air-dry, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com