Engine cylinder block water jacket

A technology for engine cylinders and cylinder blocks, applied in engine components, machines/engines, cylinders, etc., can solve problems such as weakened stiffness, low coolant flow rate, permanent deformation of the top of the cylinder block, etc., to improve heat exchange efficiency and meet cooling needs. , The effect of reducing the risk of pulling the cylinder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

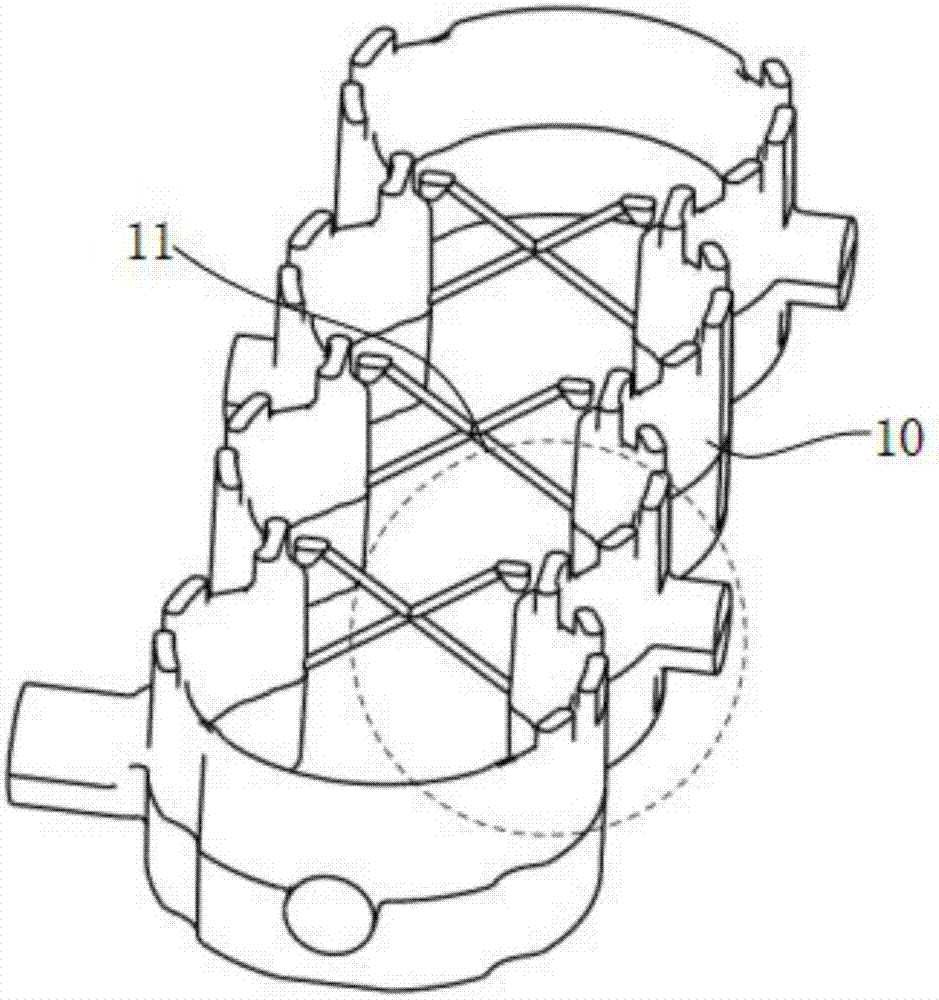

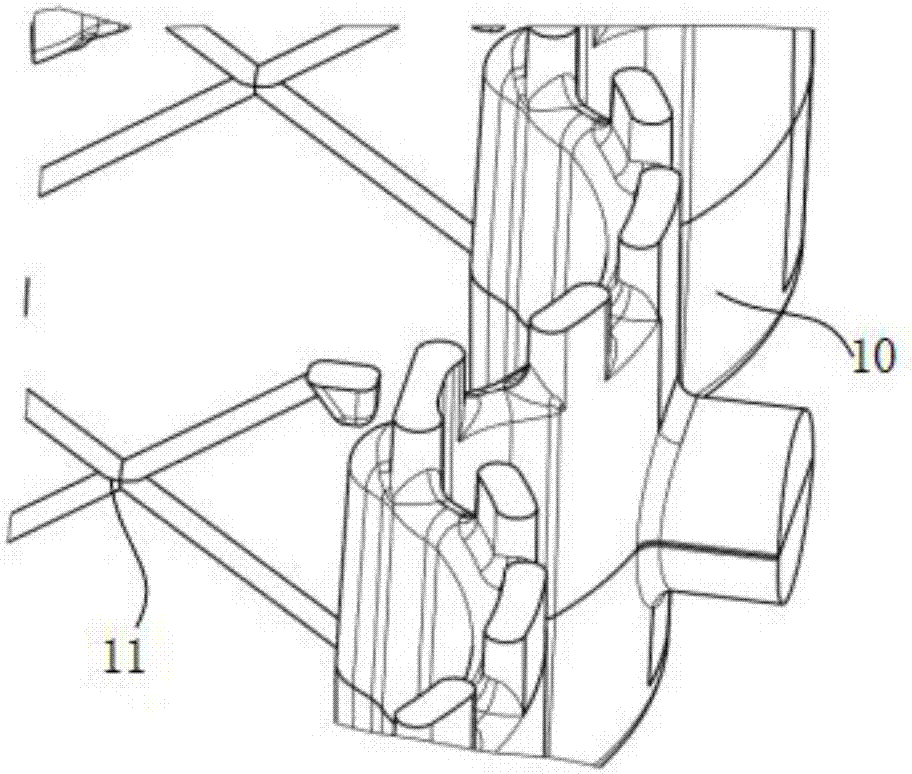

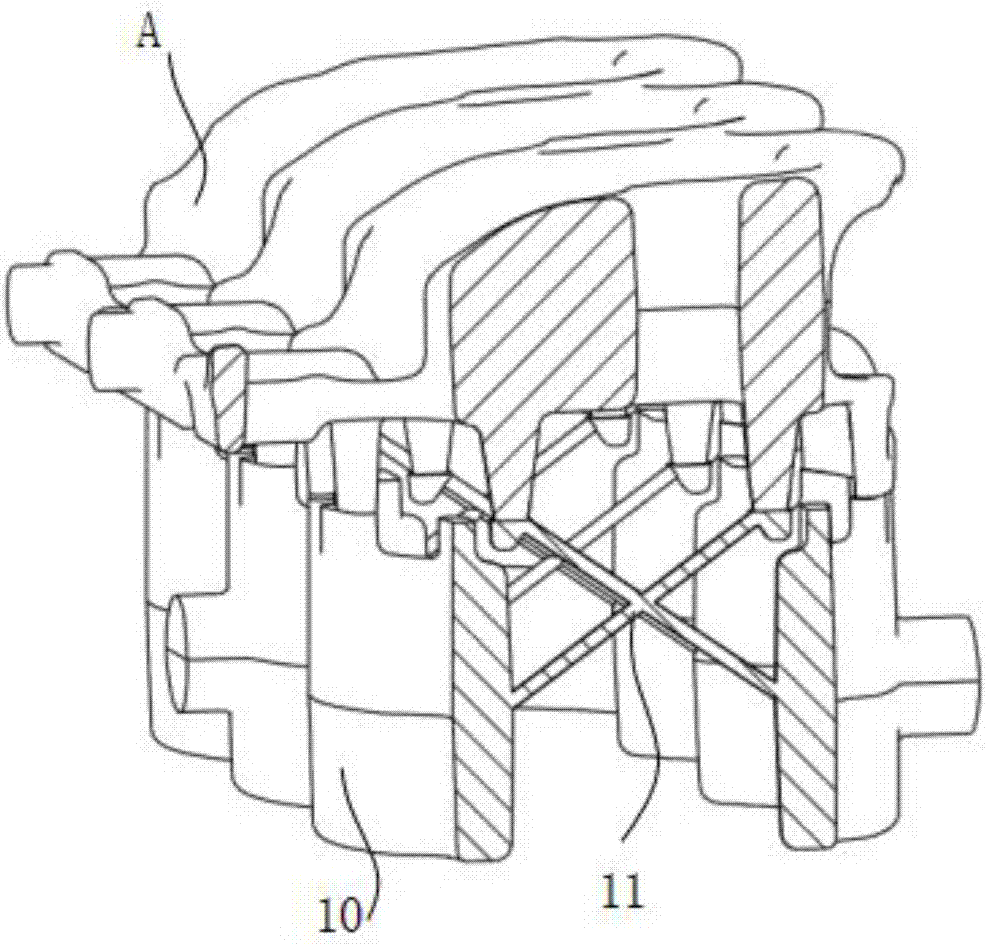

[0011] Combine below Figure 1-Figure 4 The present invention is discussed in further detail.

[0012] A water jacket for an engine cylinder block includes a water jacket body 10 surrounding the outer circumference of the cylinder bore of the cylinder block 20 to form a circulating cooling cavity. The nose area of the water jacket body 10 is provided with X-shaped water passing through the inlet and exhaust sides. Hole 11, the lower end of the X-shaped water through hole 11 communicates with the water jacket body 10, and the upper end extends to the position of the cylinder head water jacket A and communicates with the cylinder head water jacket A. In the above solution, using the pressure difference of the coolant between the cylinder block 20 and the cylinder head, the minimum flow rate of the coolant in the X-shaped water hole 11 is greatly increased, and the heat exchange efficiency with the cylinder block 20 is improved. The ability of hole 11 to control the high temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com