Carbon dioxide four-stage rotor type compression-expansion machine

A technology of compressing expander and carbon dioxide, applied in compressors, rotary piston machines, rotary piston engines, etc., can solve the problems of low cycle efficiency of energy loss, stagnation of working fluid flow, increase of complexity, etc. , the effect of reducing friction and reducing cooling loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

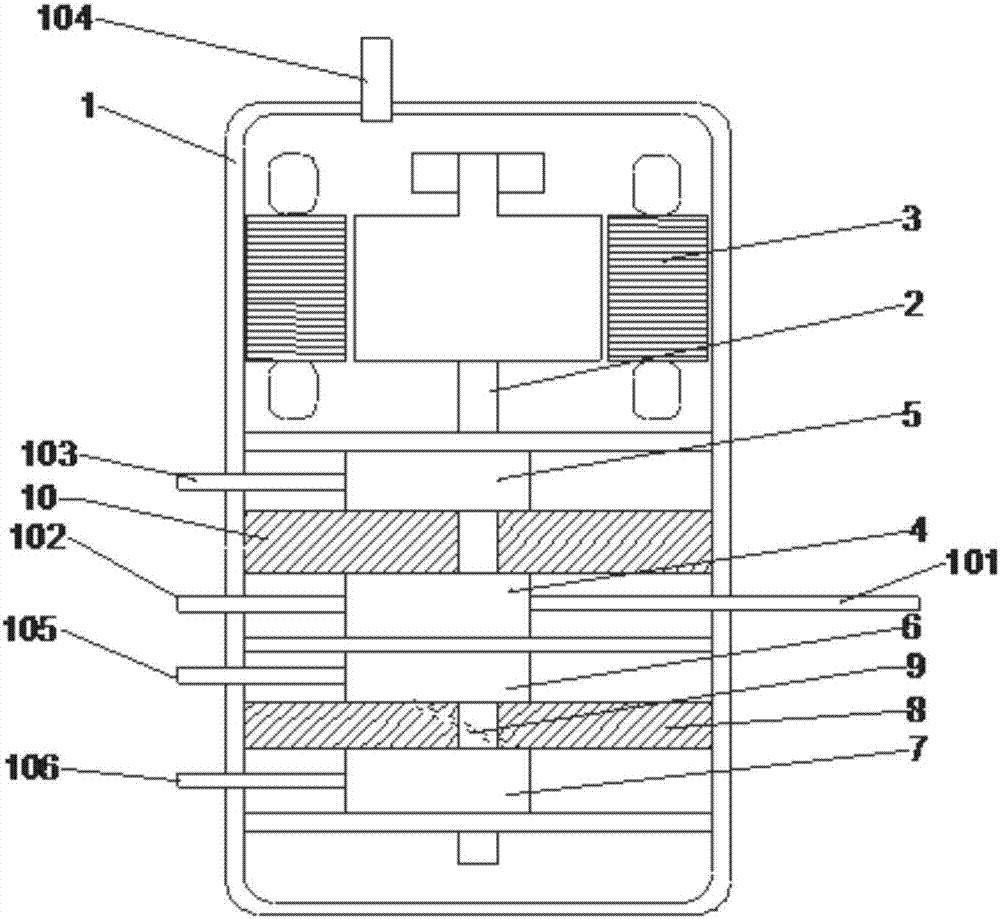

[0030] Such as figure 1 As shown, this embodiment discloses a carbon dioxide four-stage rotor type compression expander, which includes a housing 1, a motor part, a compression part, and an expansion part are arranged inside the housing 1, and the motor part, the compression part, and the expansion part are installed in the housing. 1 The interior is arranged from top to bottom, and separated from each other by baffles.

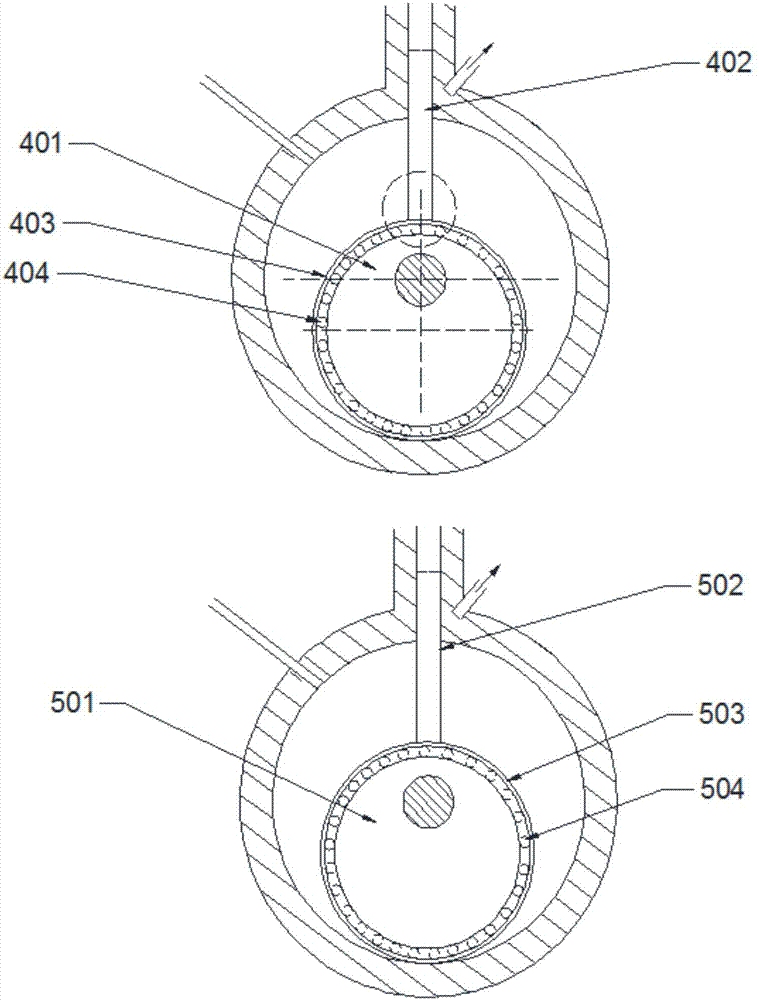

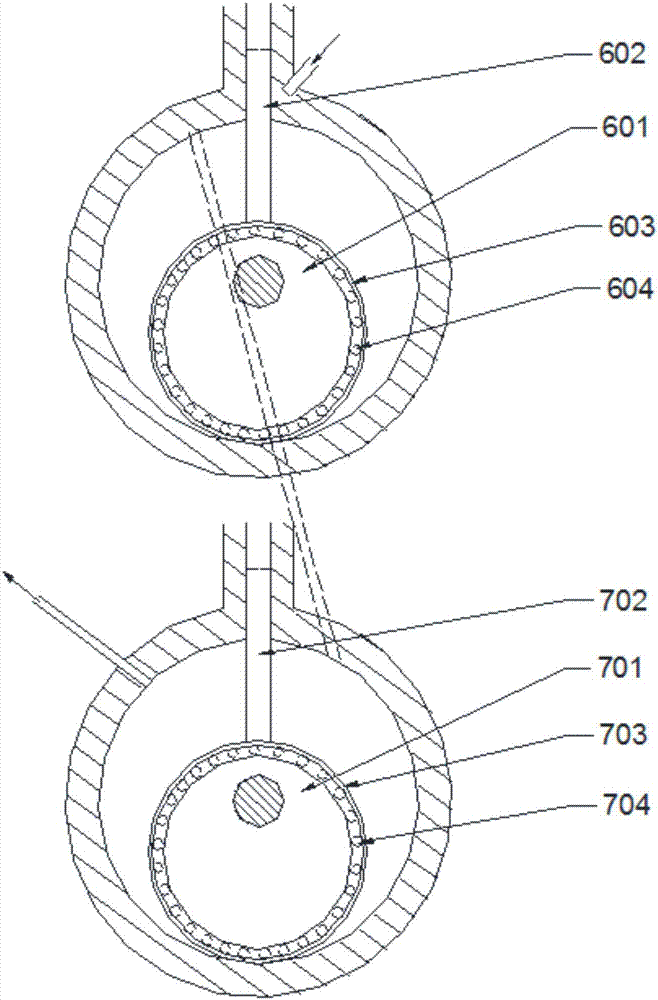

[0031]The motor part is set on the top of the housing 1, including the main shaft 2 and the coil 3, the coil 3 is wound on the main shaft 2, and the second compression cylinder 5 of the compression part, the first compression cylinder 4 and the expansion part are installed in sequence on the main shaft 2 The first expansion cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com