Magnetic suspended rotor axial displacement radial measurement method

A magnetic levitation rotor, displacement measurement technology, applied in the direction of measurement devices, electromagnetic means, instruments, etc., can solve the problems of increasing the cost of the measurement system, inconvenient installation of sensors, limited measurement range, etc., to achieve low test costs, data errors, and measurement Install simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

[0028] A radial measurement method for the axial displacement of a magnetic levitation rotor in the present invention comprises the following steps:

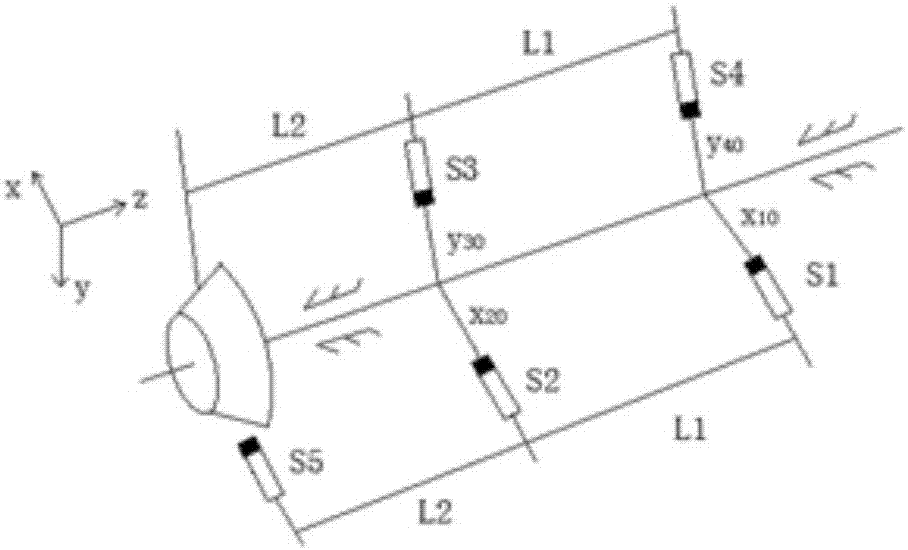

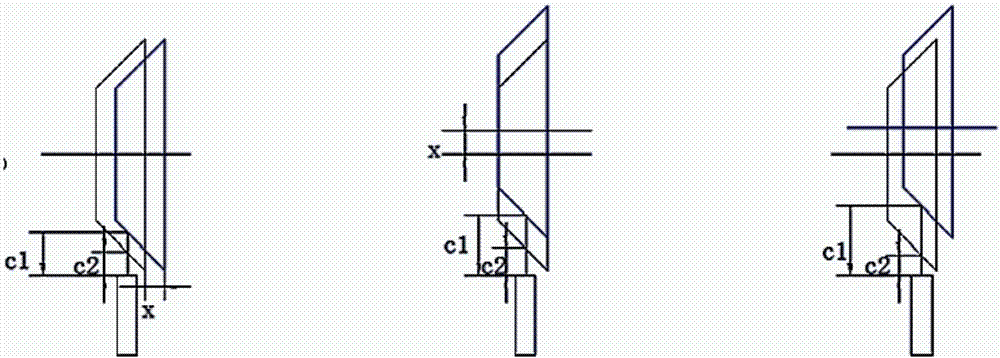

[0029] a1 provides a conical measuring block and 5 displacement measuring devices. The conical measuring block is made of magnetically conductive material; the displacement measuring device generally uses an eddy current sensor to collect the radial displacement data of the maglev rotor;

[0030] a2 Install the conical measuring block coaxially with the magnetic levitation rotor, preferably on the protruding end of the magnetic levitation bearing rotor, and the magnetic levitation bearing adopts the existing magnetic levitation bearing;

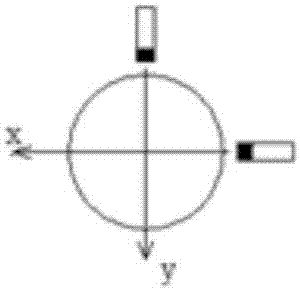

[0031] a3 Set five displacement sensors as S1, S2, S3, S4, and S5 respectively, install S1, S2, and S5 on the first installation line parallel to the axis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com