In-situ chip fixing structure of transmission electron microscope sample holder

An electron microscope and a fixed structure technology, applied in the direction of material analysis using radiation, material analysis using wave/particle radiation, and measuring devices, can solve the problems of in-situ chips that are difficult to fix, inconvenient to use, and high in use cost, and achieve Improve the effect of time cost and economic cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

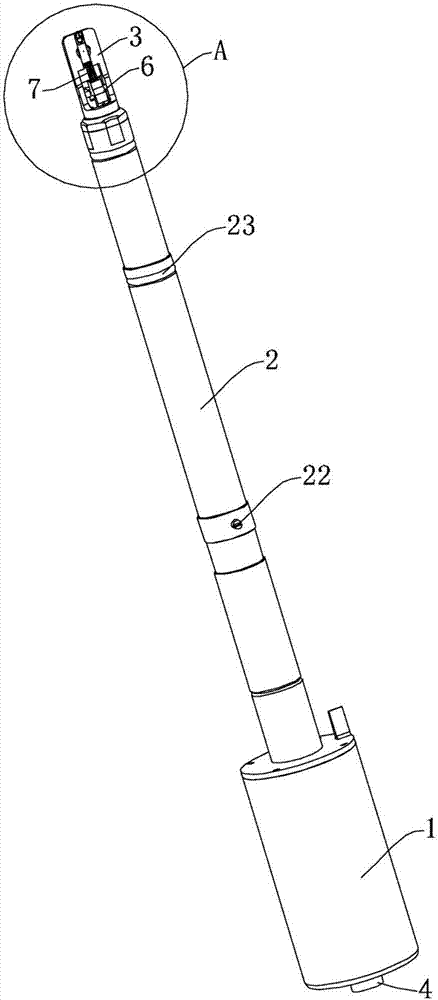

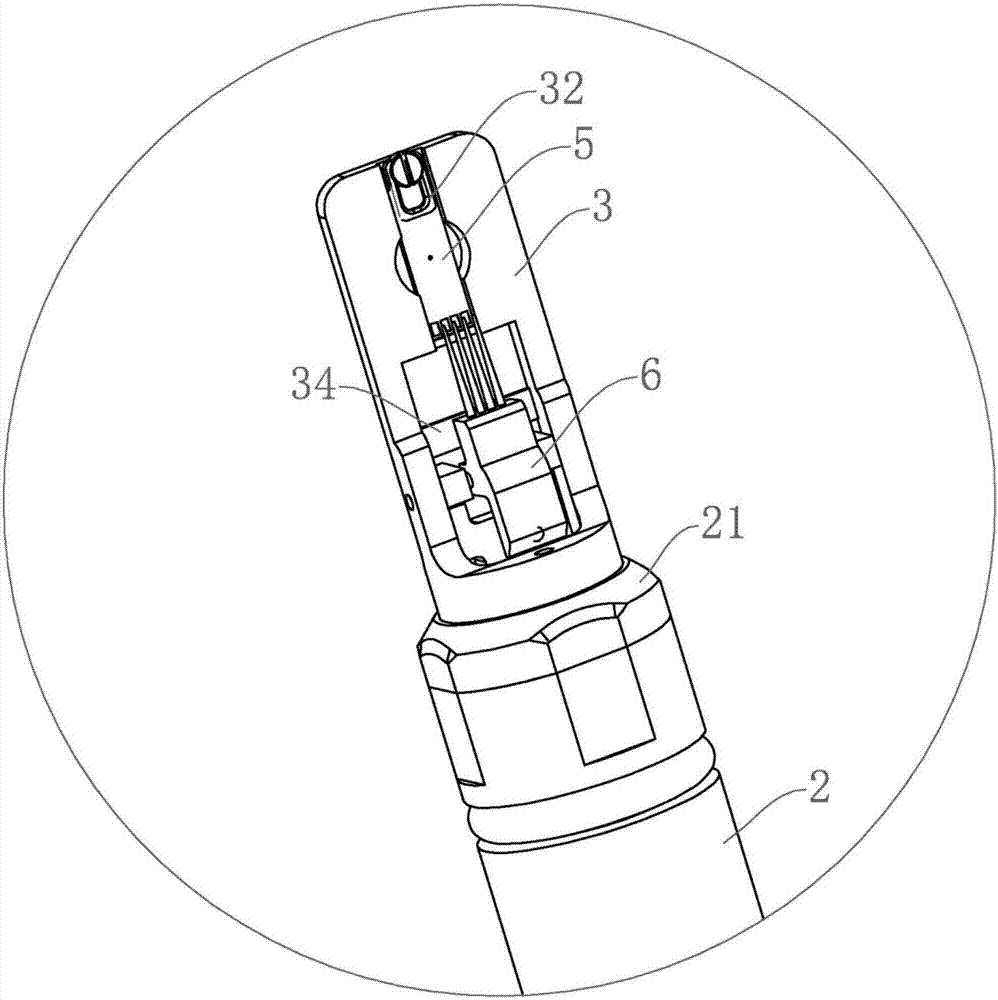

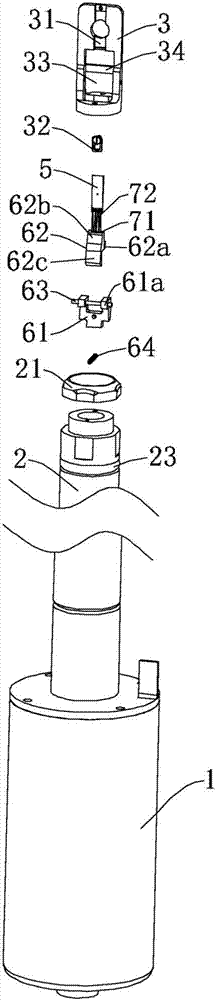

[0022] Figure 1 to Figure 3 Shown is the structural representation of the present invention.

[0023] The reference signs are: hand handle 1, sample rod main body 2, threaded end cap 21, guide pin 22, sealing ring 23, sample rod head 3, fixing groove 31, non-magnetic pressing piece 32, installation groove 33, Limiting plate 34, vacuum electrical connector 4, in-situ chip 5, conductive pin mounting seat 6, rotating base 61, lug mounting part 61a, rotating top cover 62, connecting part 62a, mounting part 62b, pressing part 62c, rotating shaft 63, non-magnetic spring 64, non-magnetic conductive needle 7, needle tube 71, needle point 72.

[0024] Such as figure 1 As shown, an in-situ chip fixing structure for a transmission electron microscope sample rod of the present invention includes a handle 1 , a sample rod body 2 , a sample rod head 3 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com