High-voltage compound explosion prevention type three-phase asynchronous motor

A three-phase asynchronous, explosion-proof technology, used in electric components, electrical components, electromechanical devices, etc., can solve problems such as high safety hazards and no dust explosion-proof.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

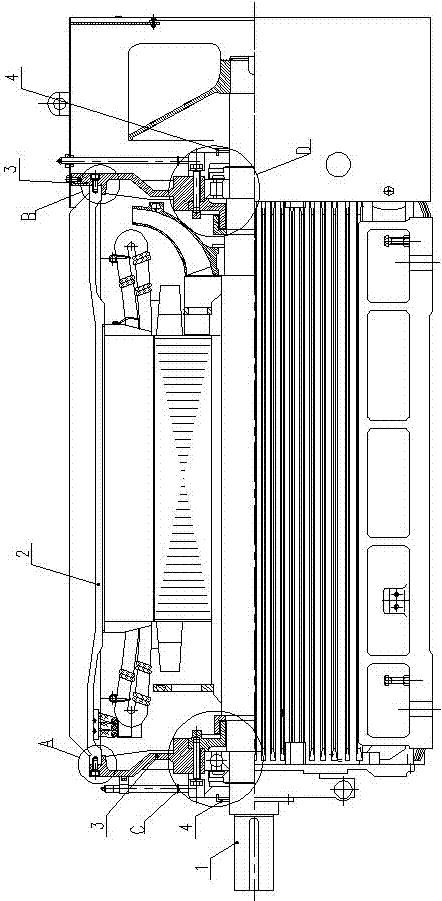

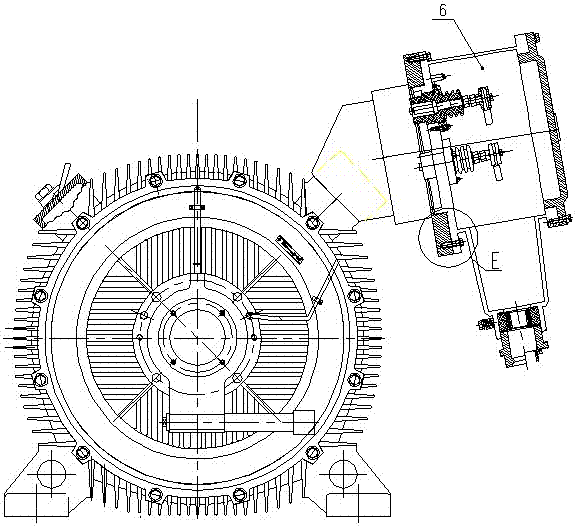

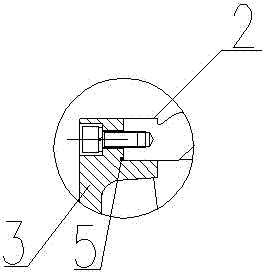

[0022] Such as Figure 1 to Figure 7 As shown, a high-voltage composite explosion-proof three-phase asynchronous motor of the present invention includes a base 2 and a rotating shaft 1, and end covers 3 are respectively provided at the front and rear ends of the base 2, and the cooperation between the end cover 3 and the rotating shaft 1 There is a flameproof structure to prevent combustible dust from entering the bearing chamber or the inside of the motor. The flameproof structure includes a labyrinth seal sleeve 4 fixedly sleeved on the shaft 1. The labyrinth seal sleeve 4 is located outside the motor and coaxial with the shaft 1. set, and the labyrinth sealing sleeve 4 is composed of a radial retaining ring and an axial cylinder, the inner ring of the retaining ring is sealed and fixedly connected with the rotating shaft 1, and the outer ring of the retaining ring is sealed and fixedly connected with the outer end of the cylinder. The inner end of the cylinder extends axial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com