Brushless DC motor torque ripple suppression method based on current hysteresis control

A brushed DC motor, current hysteresis technology, applied in the direction of torque ripple control, current controller, etc., can solve problems such as restricting applications, achieve simple and feasible methods, suppress commutation torque ripple, improve dynamic performance and robustness sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

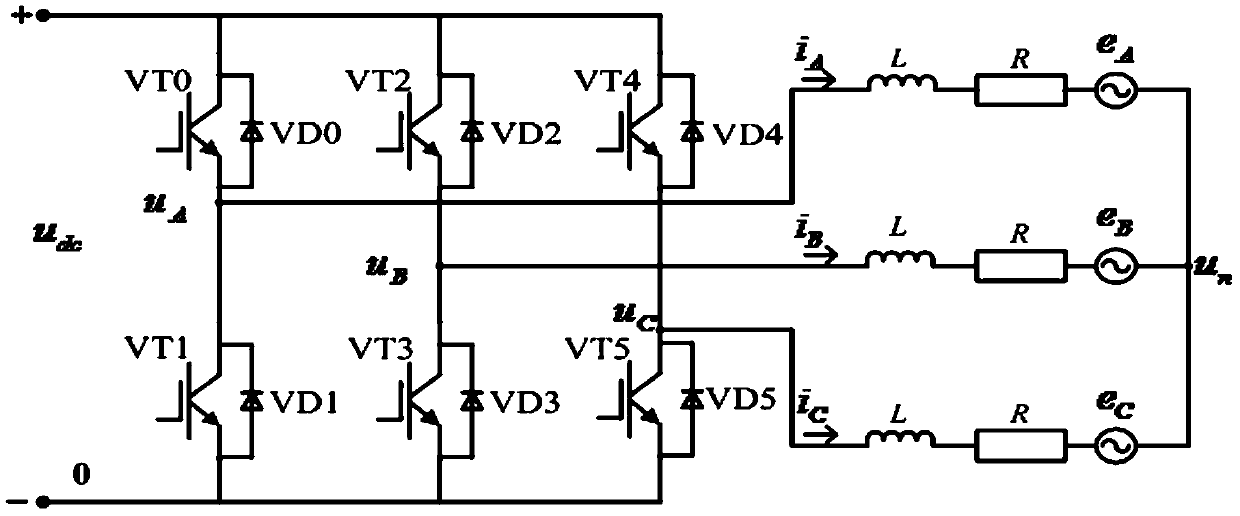

[0025] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

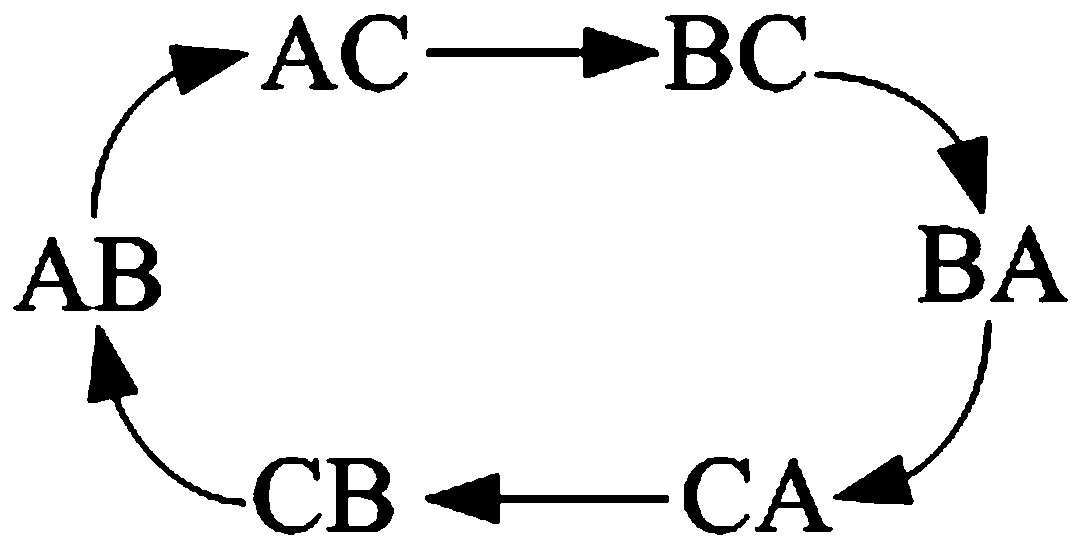

[0026] Such as Figure 4 As shown, a brushless DC motor torque ripple suppression method based on current hysteresis control, the specific implementation process is as follows:

[0027] Process 1: Determine the rotor position and speed calculation based on the Hall signal.

[0028] Process 2: The design of the outer ring of the speed and the setting of the inner ring of the regulator output.

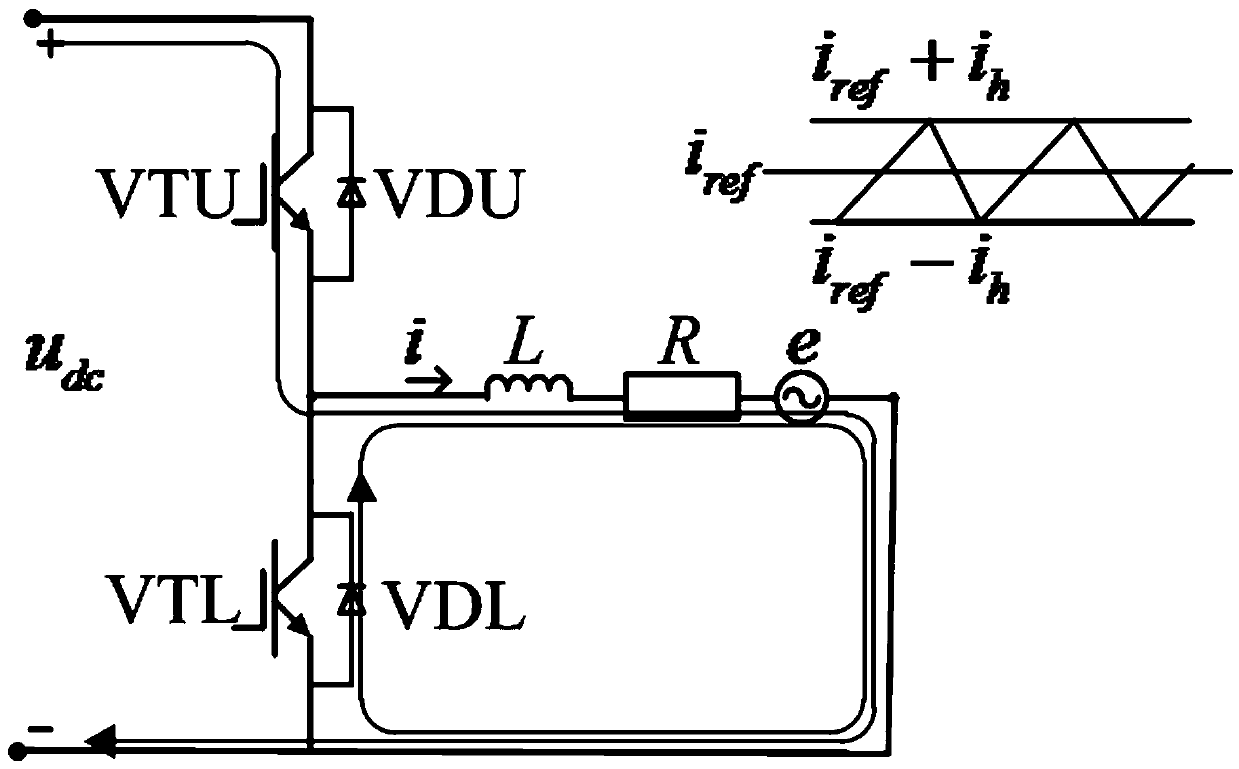

[0029] Process 3: The current given amount output by the outer loop is compared with the current feedback amount of the inner loop, controlled by the current hysteresis loop, and combined with the rotor position signal, the corresponding power tube is controlled to be turned on and off.

[0030] Process 1 includes the follow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com