Coating air-drying equipment based on air filtration system

A kind of air filtration and air filter technology, which is applied in the direction of coating, dispersed particle filtration, gas treatment, etc., can solve the problems of affecting the quality of the coating film, the adverse effect of the coating film quality, and the natural wind containing a large amount of impurities and moisture, etc., to achieve Improve drying efficiency, speed up drying rate, good gloss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

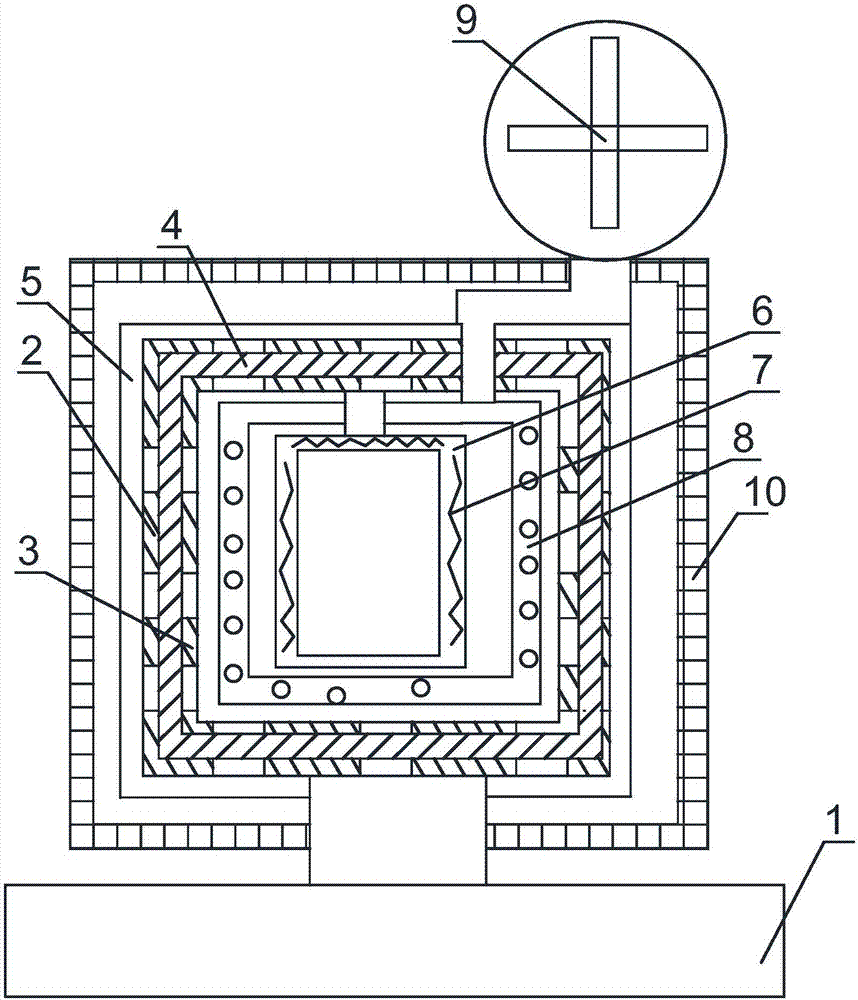

[0022] Such as figure 1 Shown, the present invention is based on the coating air-drying equipment of air filter system, comprises base 1, is connected with air filter above described base 1, and described air filter comprises the outer box body 2 that is surrounded by rough filter screen, is made of The inner box body 3 surrounded by the high-efficiency filter screen, the outer box body 2 and the base 1 are connected and fixed, the inner box body 3 is located inside the outer box body 2, and an activated carbon net 4 is arranged between the inner box body 3 and the outer box body 2, so that The activated carbon net 4 connects the inner box body 3 with the outer box body 2, the outer wall of the outer box body 2 is completely covered with a drying bag 5 with a desiccant inside, and the inside of the inner box body 3 is provided with a fixed coating film substrate The fixed frame 6 is equipped with a heater 7 inside the frame wall of the fixed frame 6.

[0023] In the present i...

Embodiment 2

[0025] Based on embodiment 1, the inside of the inner box 3 is provided with an annular pipe 8, the fixed frame 6 is on the inner side of the annular pipe 8, the annular pipe 8 is connected with an exhaust fan 9, and the exhaust fan 9 is located outside the outer box 2, The annular pipe 8 is provided with a plurality of evenly distributed through holes.

[0026] The exhaust fan is used to extract the air inside the inner box, which is convenient for ventilation treatment. The gas inside the inner box is drawn out from the annular tube. On the one hand, it controls the flow rate of the wind during the exhaust process, and avoids the wind flowing too fast and affecting the substrate. The shape of the film whose surface is not fully formed; on the other hand, it ensures that the air surrounding the coated film substrate is replaced as completely as possible.

[0027] implementation, 3

[0028] Based on the above-mentioned embodiment, a hollow protective cover 10 is installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com