Horn manufacturing system and control method thereof

A technology for making systems and speakers, applied in the direction of manufacturing tools, sensors, metal processing, etc., can solve the problems of low precision, unfavorable mass and rapid production, low production efficiency, etc., to reduce costs, improve production efficiency and product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

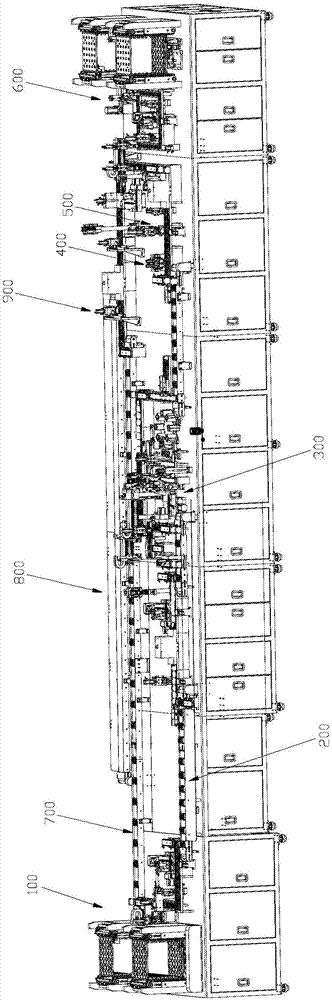

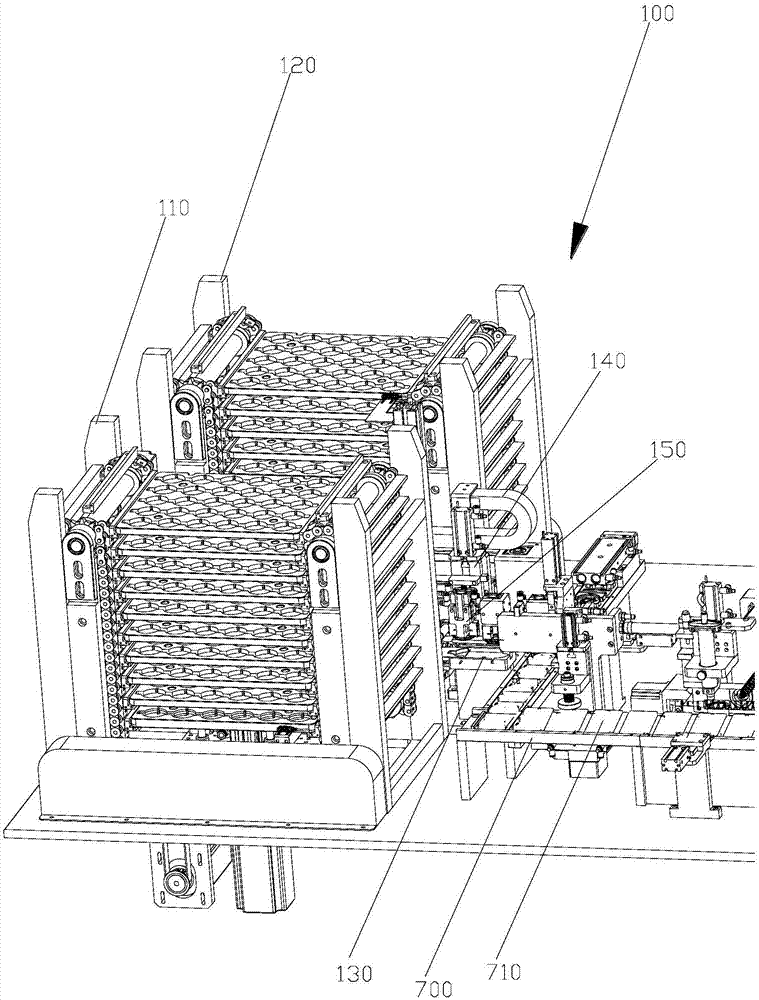

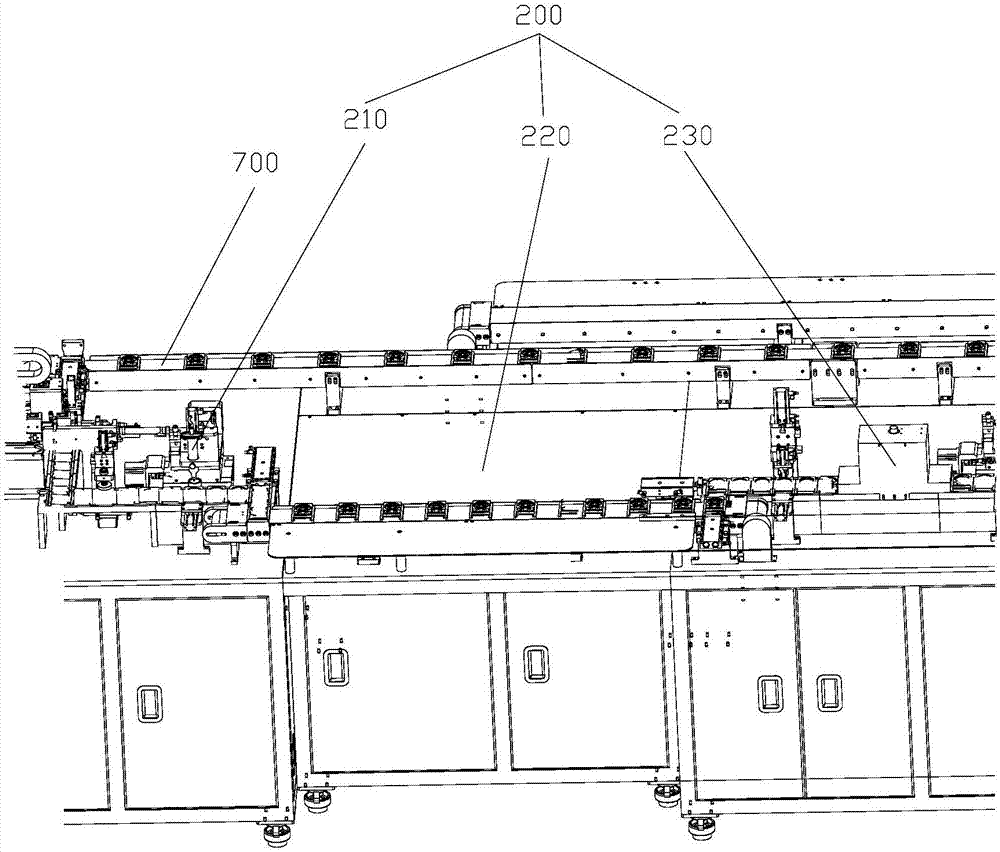

[0041] Such as Figure 1 to Figure 11As shown, the speaker manufacturing system provided by the present invention includes an annular transmission channel 700, and along the transmission channel 700, a first loading and swinging device 100, a first assembly device 200, a second assembly device 300 and a first assembly device 300 are arranged in sequence. 2. Loading and swinging device 600. After the frame body enters the conveying channel 700 from the first loading and swinging device 100, it passes through the first assembly device 200 to complete the turn ring assembly, passes through the second assembly device 300 to complete the sheet assembly, and passes through the The second loading and swinging device 600 completes the magnetic block assembly.

[0042] The first loading and swinging device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com