Lock cylinder shell machining device

A technology for processing devices and lock cylinder shells, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve problems such as damage, worker fatigue and distraction, fingers involved in equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

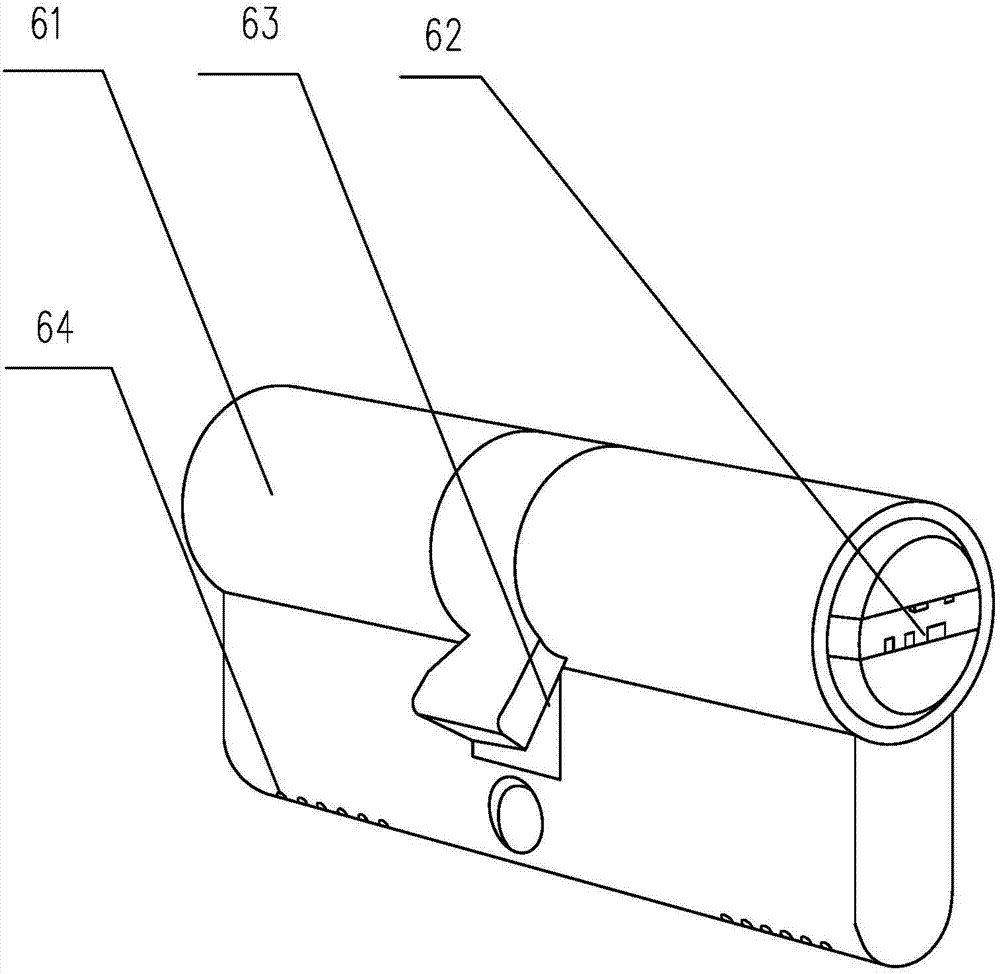

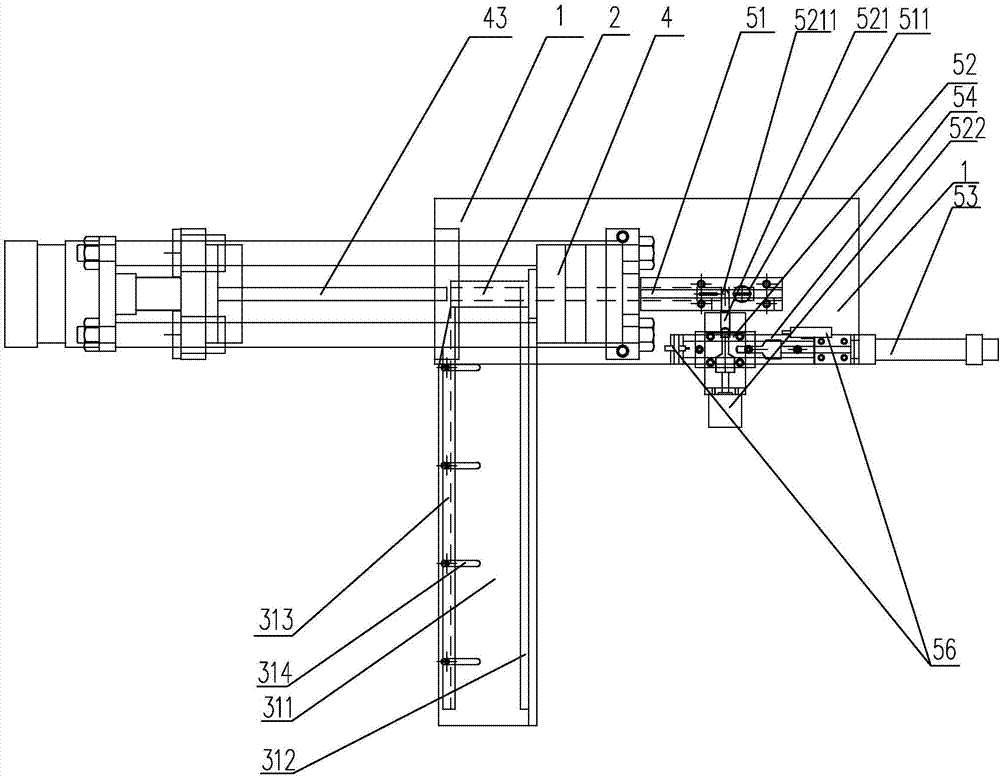

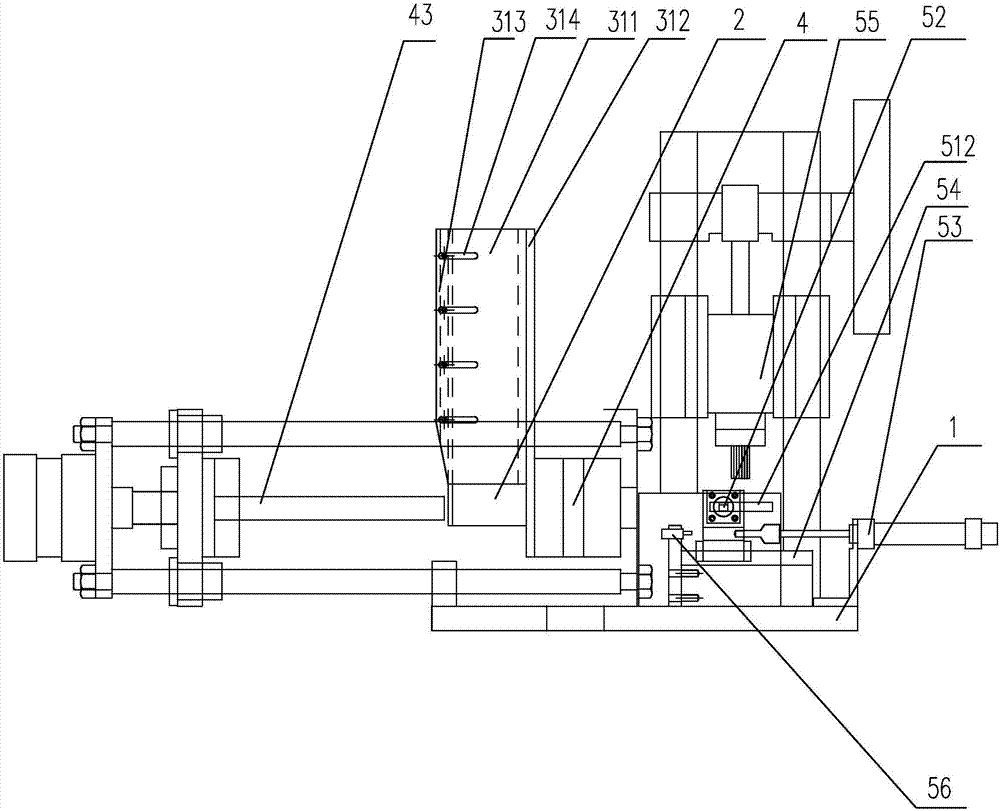

[0028] Depend on Figure 1 to Figure 6It can be seen that the present invention discloses a lock cylinder shell processing device, including a bracket 1, a feeding mechanism, a cutting mechanism 4 and a punching mechanism for punching the lock cylinder shell after the cutting is completed. The mechanism includes a punching chamber 51 and a punching machine 55. The feeding mechanism includes a housing chamber 2 and a feeding track for feeding materials into the housing chamber 2. The feeding track includes a bearing slide 31, and the bearing The slideway 31 is provided with a baffle plate 32 to prevent the lock core shell from turning over. The bearing slideway 31 includes a bearing bottom surface 311, a first side wall 313 and a second side wall 312. The bearing bottom surface 311 is provided with Adjustment groove 314, the second side wall 312 is fixed on the bearing bottom surface 311, the first side wall 313 is arranged on the adjustment groove 314 slidably along the adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com