Device for cutting rebars among pre-stressed sleepers

A cutting device and prestressing technology, applied in the direction of grinding/polishing safety devices, grinding machines, metal processing equipment, etc., can solve the problem of not meeting people's needs well, hard or soft, affecting the normal sleeper Use and other issues to achieve the effects of improving service life and use accuracy, preventing pollution, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

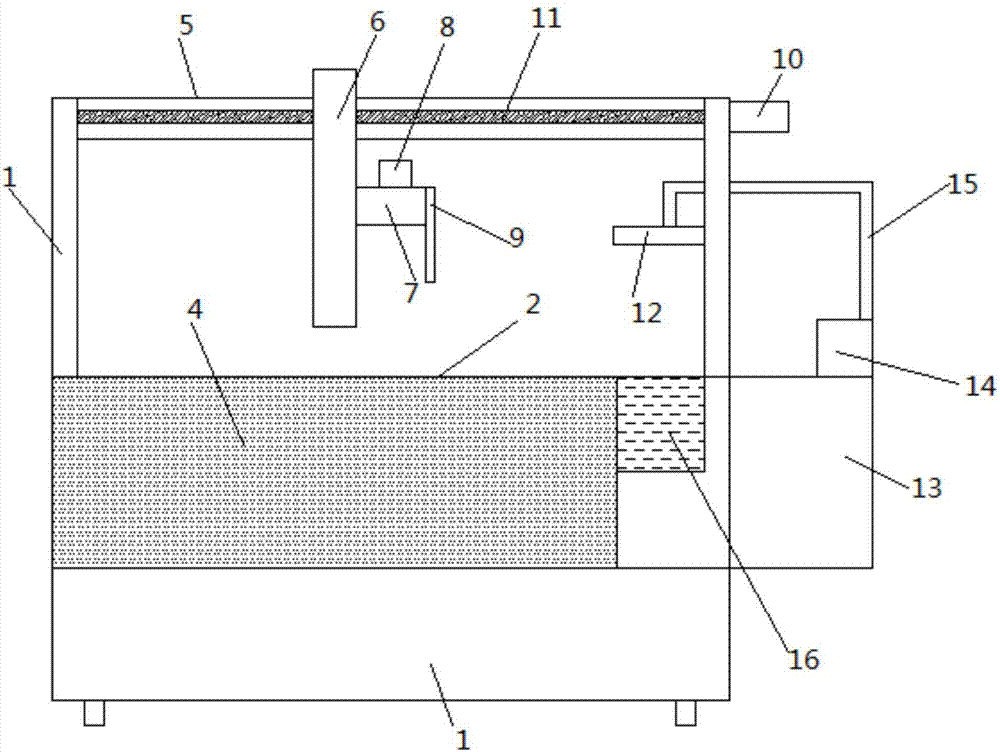

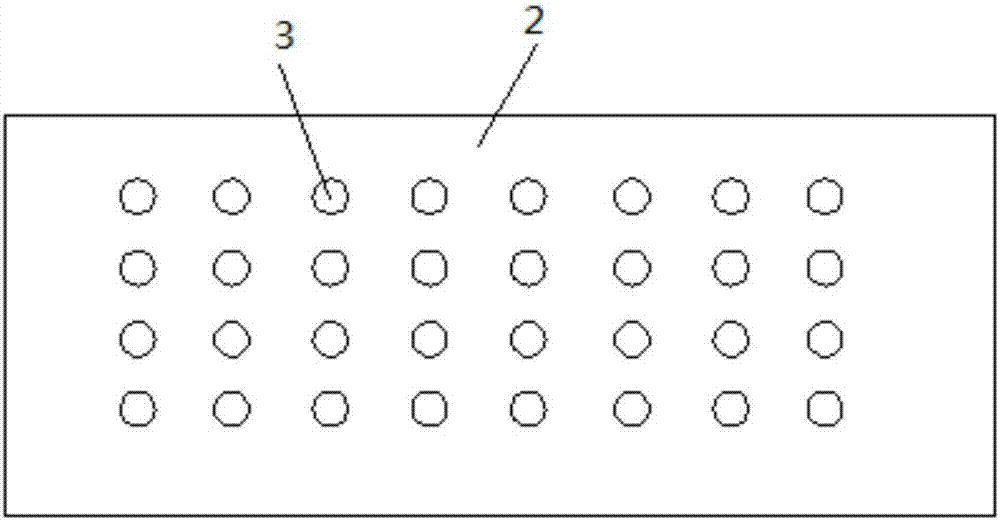

[0014] Refer to attached Figure 1-2 , the present invention provides a steel bar cutting device between prestressed sleepers, comprising a frame 1, a working platform 2 is arranged on the frame 1, a powder cleaning hole 3 is arranged on the working platform 2, and a collecting hole 3 is arranged below the powder cleaning hole 3. The powder box 4, the upper end of the frame 1 is provided with a crossbeam 5, the crossbeam 5 is slidably provided with a longitudinal fixing plate 6, and one end of the crossbeam 5 is provided with a driving device, the driving device is movably connected with the longitudinal fixing plate 6, and the longitudinal fixing plate 6 The upper slidably is provided with cutting device, and described cutting device comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com